Refrigerator centralized cold source carbon dioxide cascade refrigeration system and refrigeration method

A carbon dioxide, cascade refrigeration technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of unconcentrated distribution of freezers, increase the operating cost of freezer refrigeration systems, etc., achieve superior thermodynamic performance, reduce energy consumption, The effect of uniform liquid supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

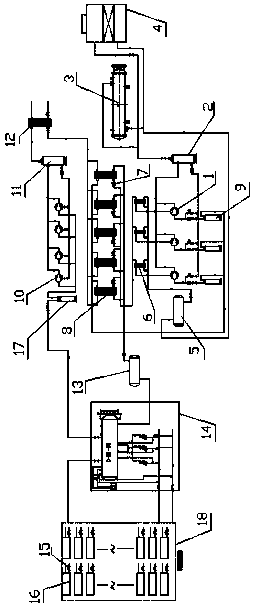

Embodiment 1

[0021] A carbon dioxide cascade refrigeration system with a centralized cold source for a freezer, which comprises: an R134a compressor 1 and an R744 compressor 10, and the R134a compressor is connected to a secondary oil separator 2, an economizer 6 and an R134a gas-liquid separator respectively 9 connection, the secondary oil separator is connected to the shell-and-tube heat exchanger 3, the shell-and-tube heat exchanger is connected to the evaporative condenser 4, and the evaporative condenser is connected to the R134a liquid receiver 5 , the R134a liquid reservoir is connected to the economizer, the economizer is connected to the expansion valve 7, the expansion valve is connected to the condensing evaporator 8, and the condensing evaporator is respectively connected to the The R134a gas-liquid separator, the desuperheater 12 and the R744 liquid reservoir 13 are connected.

Embodiment 2

[0023] According to the carbon dioxide cascade refrigeration system of the freezer centralized cold source described in embodiment 1, the R744 compressor is connected to the R744 oil separator 11 and the R744 gas-liquid separator 17 respectively, and the R744 oil separator is connected to the R744 oil separator To remove the superheater connection, the R744 gas-liquid separator is connected to the R744 low-pressure circulation barrel skid block 14, and the R744 low-pressure circulation barrel skid block is connected to the R744 liquid reservoir and the freezer group 18 respectively.

Embodiment 3

[0025] According to the carbon dioxide cascade refrigeration system with concentrated cold source of the freezer described in embodiment 1 or 2, the freezer group is 1200 freezers, the freezer group is composed of an electronic expansion valve 15 and a freezer 16, and the freezer is connected with the freezer The electronic expansion valve connection described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com