Imaging method and device for track board internal defect detection

A technology for internal defects, imaging methods, applied to measuring devices, processing response signals of detection, analysis of solids using acoustic/ultrasonic/infrasonic waves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

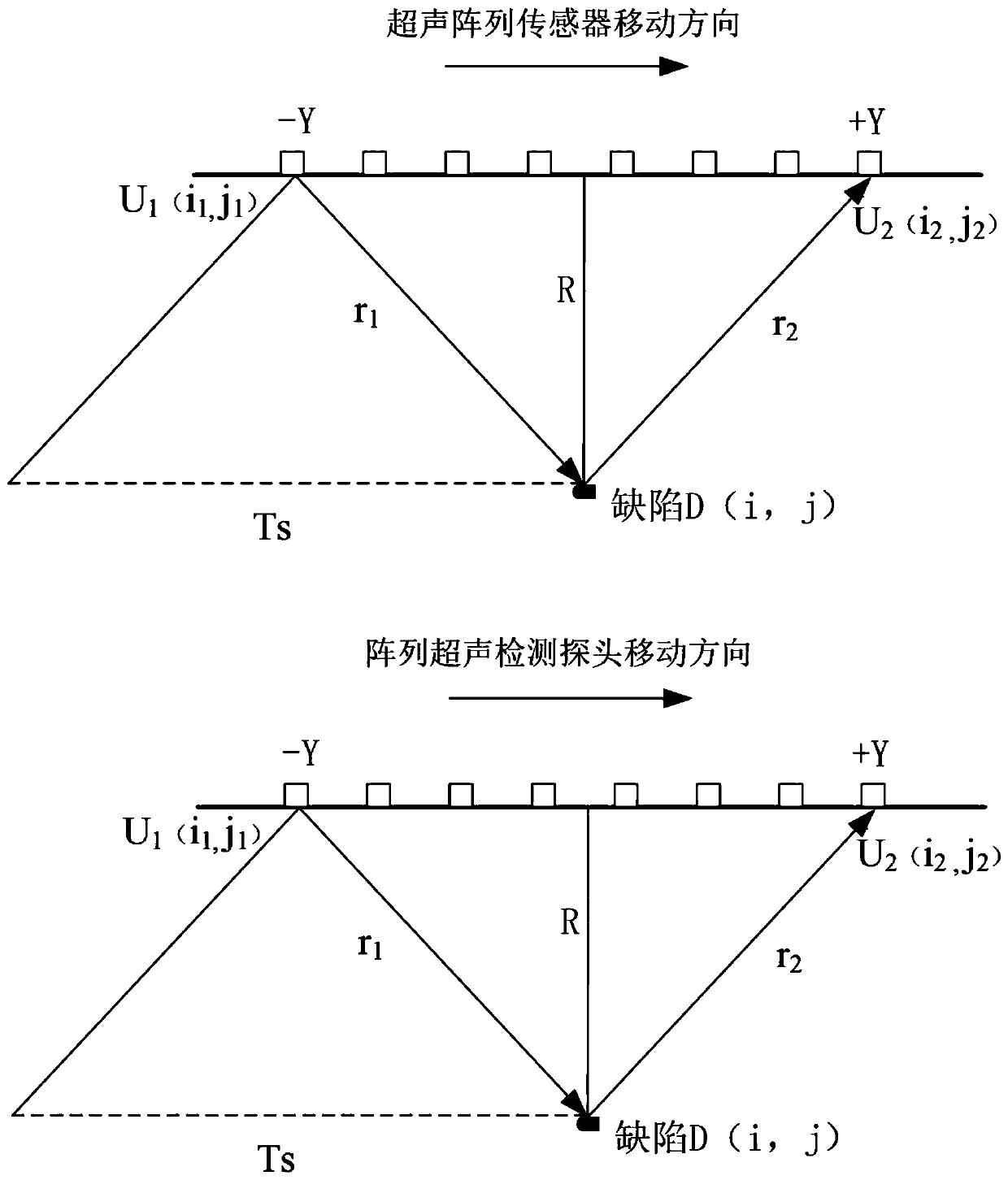

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

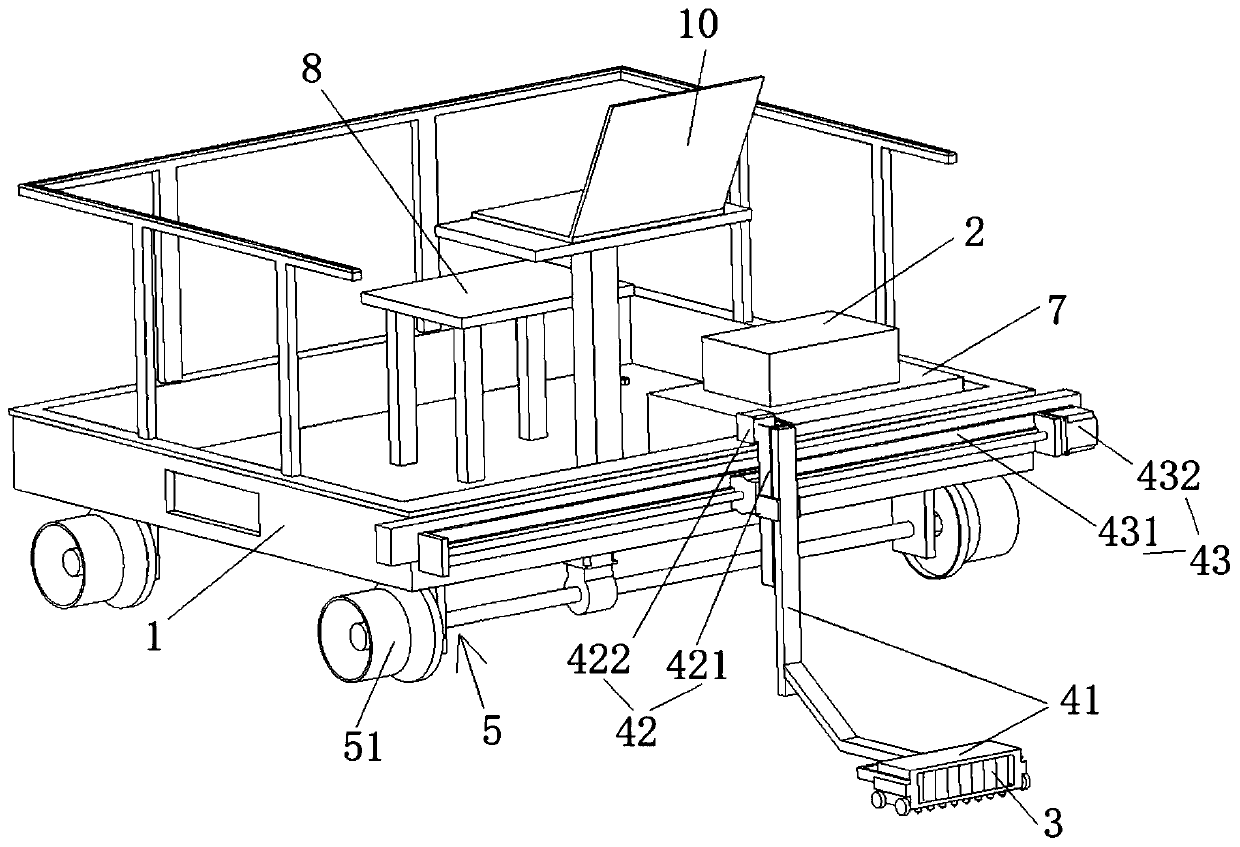

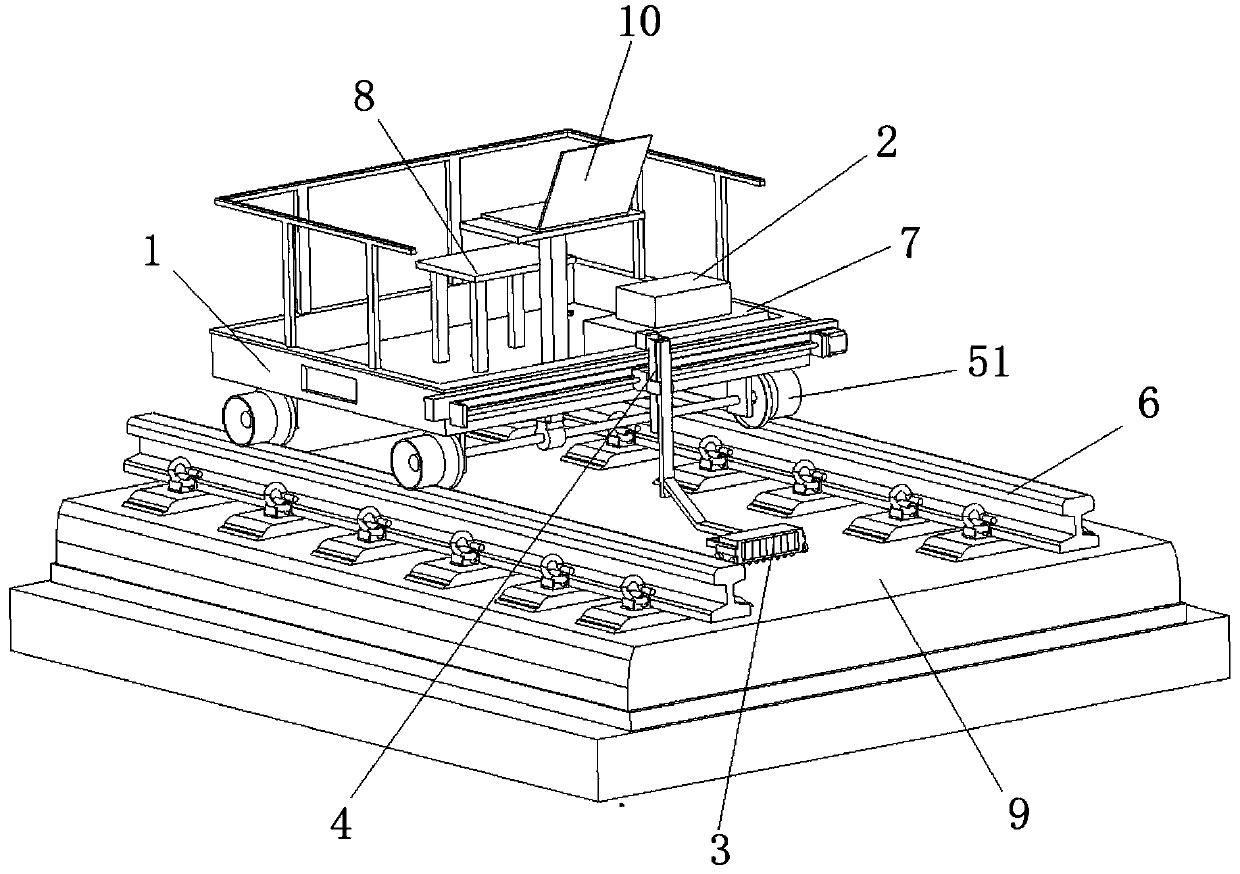

[0071] combine Figure 2 to Figure 4 Shown: an imaging device for internal defect detection of track slabs provided by the present invention, including a track inspection trolley 1 and an ultrasonic transmitter receiver 2 and a computer 10 arranged on the track inspection trolley 1, the ultrasonic transmitter receiver 2 Comprise ultrasonic signal excitation unit 21 and ultrasonic signal receiving unit 22, also comprise ultrasonic array sensor 3, the transmission end of described ultrasonic array sensor 3 is connected with ultrasonic signal excitation unit 21 signal, the receiving end of described ultrasonic array sensor 3 is connected with ultrasonic signal The receiving unit 22 is connected to the signal, the ultrasonic signal receiving unit 22 is connected to the computer 10, the ultrasonic array sensor 3 is connected to an adaptive displacement feedback adjustment device 4, and the adaptive displacement feedback adjustment device 4 is fixedly connected to the The front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com