Method for determining maximum field intensity of intermediate joint for medium-low-voltage direct-current XLPE cable

An intermediate joint, medium and low voltage technology, applied in electrical digital data processing, instruments, computer-aided design, etc., can solve problems such as time-consuming iterative process, complex modeling, and difficulty in mastering, and achieve strong universality and meet engineering requirements. The effect of application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

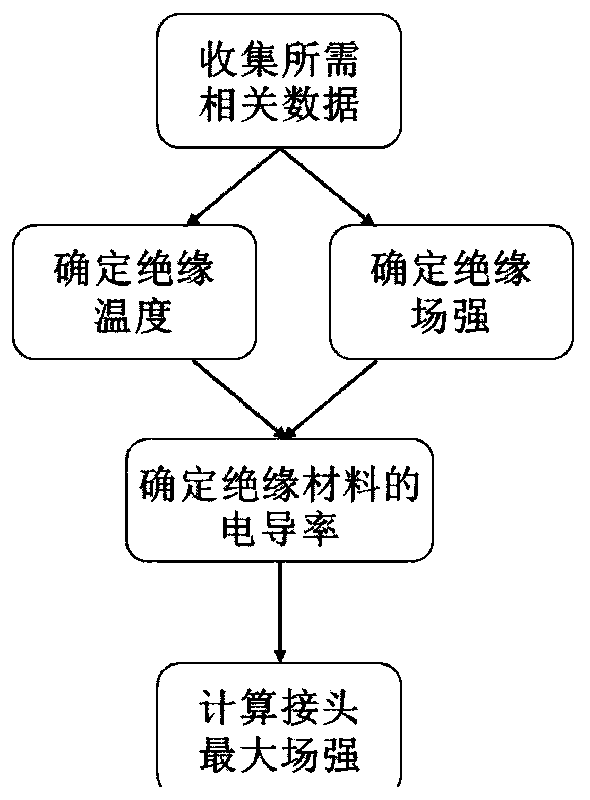

[0060] Utilize the method proposed by the present invention to calculate the maximum field strength of the 10kV DC XLPE cable with the intermediate joint running under different loads after the AC transformation of the medium and low-voltage cable lines into DC operation, such as image 3 shown, including the following steps:

[0061] Step 1: Gather required relevant data

[0062] 1) Determine the size parameters of the joint

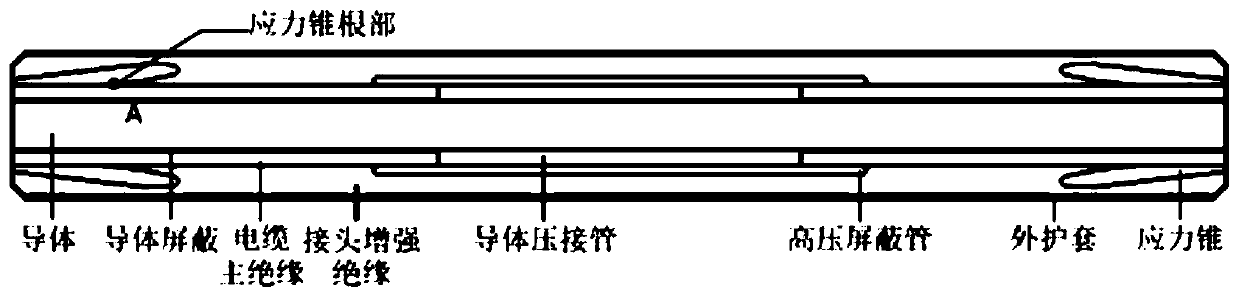

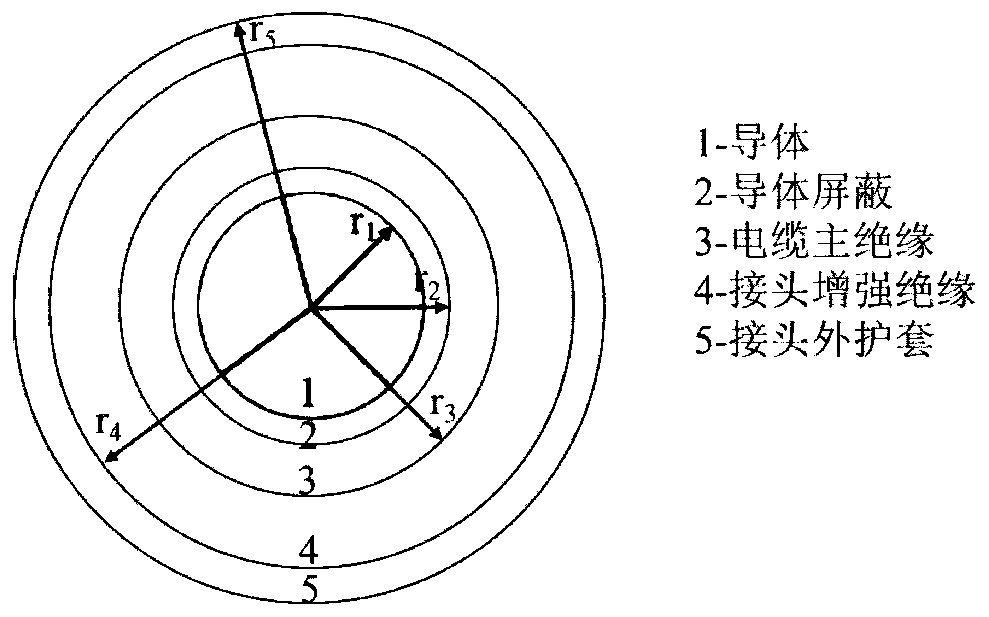

[0063] Such as figure 1 with figure 2 As shown, adopt YJV22-8.7 / 15-3×240mm 2 The 10kV XLPE cable joint is used as the calculation object, and the reinforced insulation material of the joint is silicone rubber (SIR). According to the data provided by the manufacturer, the conductor radius r 1 =9.15mm, conductor shielding radius r 2 =9.95mm, cable main insulation radius r 3 =14.45mm, reinforced insulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com