Superconducting conductor high-precision hole shrinkage method and device

A superconducting conductor, high-precision technology, applied in superconducting/high-conducting conductors, usage of superconducting elements, superconducting devices, etc., can solve the problem of high processing site requirements, high consistency requirements for installation accuracy, and unsatisfactory precision Requirements and other issues, to achieve the effect of high shrinkage forming precision and stable operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

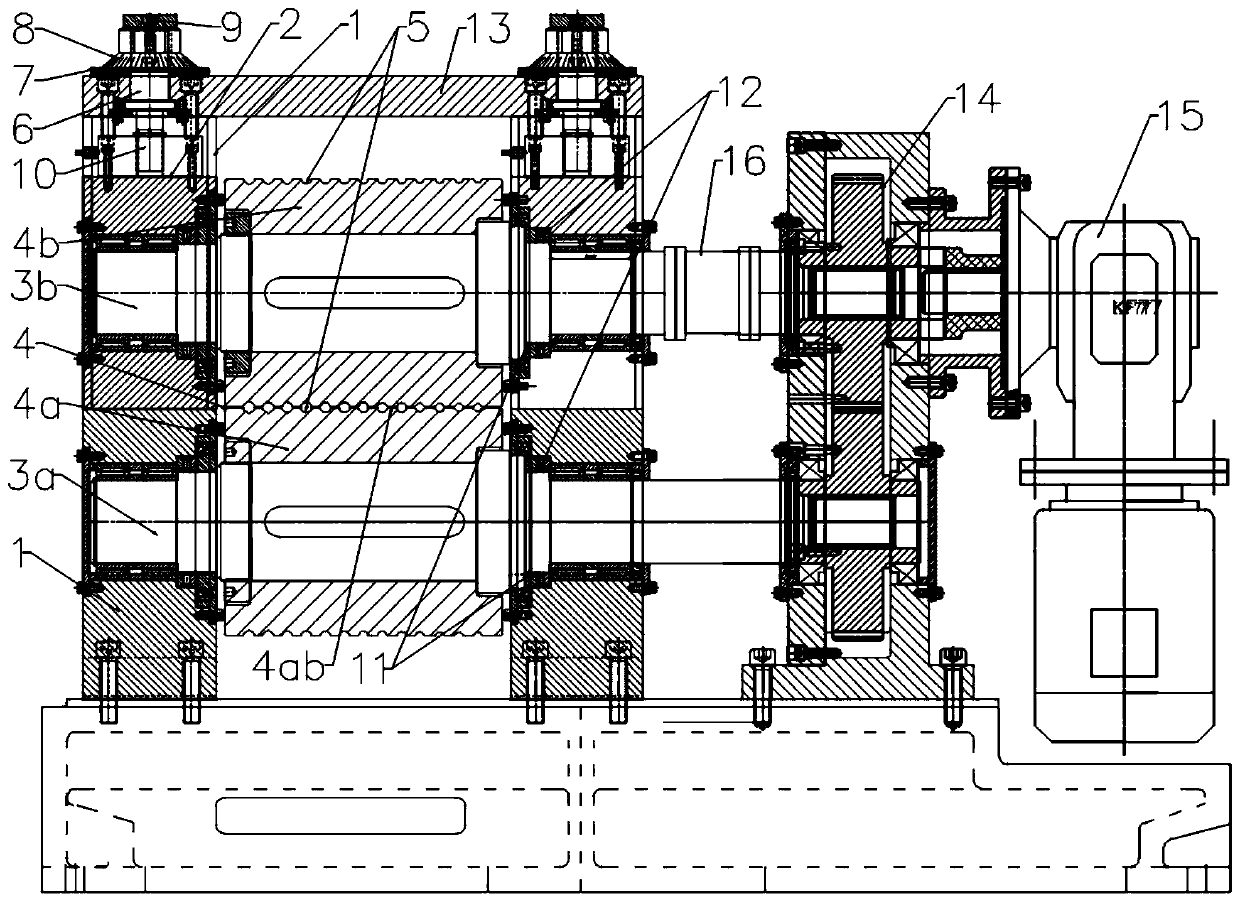

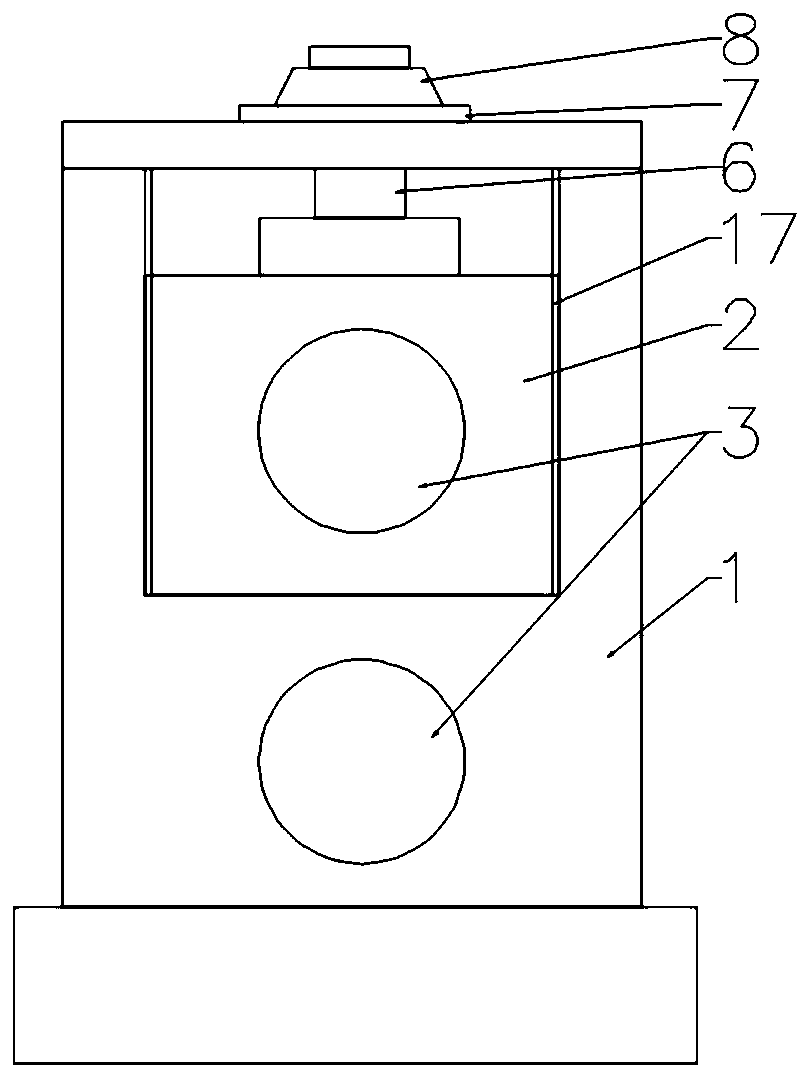

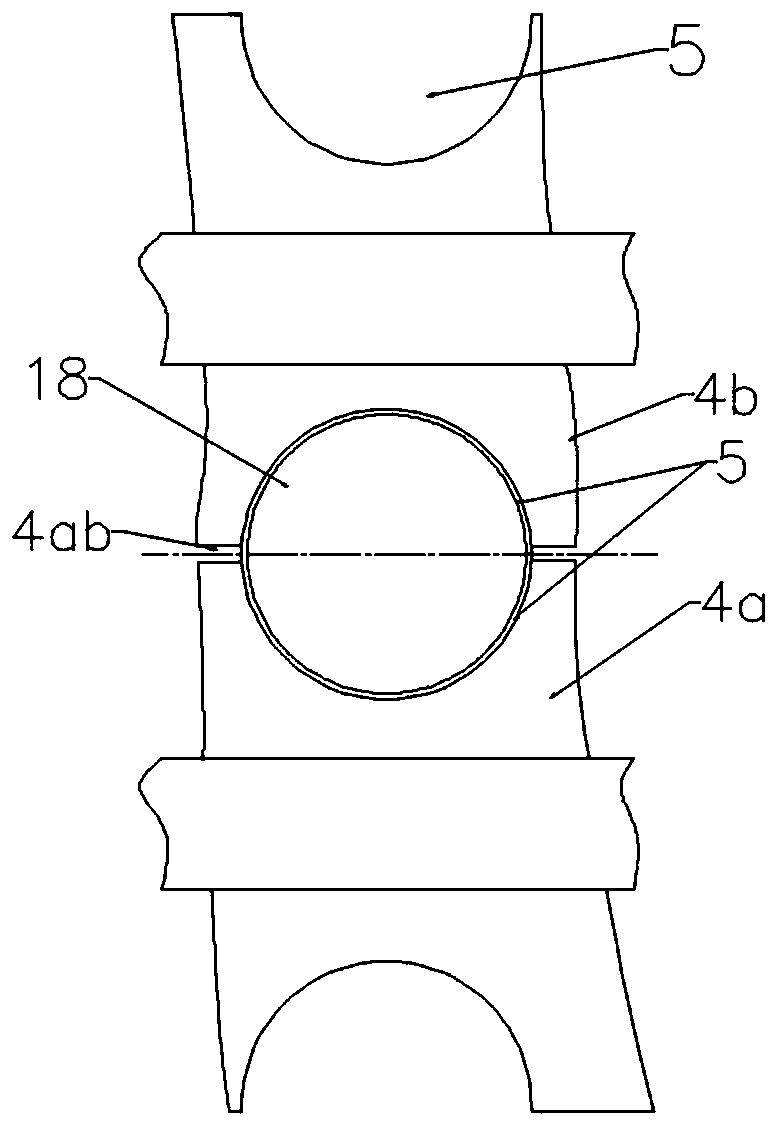

[0011] In order to facilitate a better understanding of the present invention, the present invention will be further described below with reference to the accompanying drawings.

[0012] The high-precision diameter reduction method of superconducting conductors is to reduce or enlarge several pairs of forming die grooves according to a certain ratio and set them on one or several pairs of rollers, and use the several pairs of forming die grooves on the pair of rollers to make superconducting According to the required total diameter reduction, the conductor is rolled and extruded to reduce the diameter step by step according to a ratio.

[0013] Several pairs of rollers are arranged in turn corresponding to several pairs of mold grooves that are reduced or enlarged in the same or / and different proportions. When measuring, use another pair or several pairs of rollers with the same die cavity specifications, the same or different diameter reduction ratios to carry out rolling ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com