Three-dimensional memory manufacturing method and three-dimensional memory

A manufacturing method and memory technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problem of difficult control of gate seam etching depth, achieve precise control of etching precision, reduce etching Depth, the effect of reducing machining errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the present invention is not limited to the following specific embodiments.

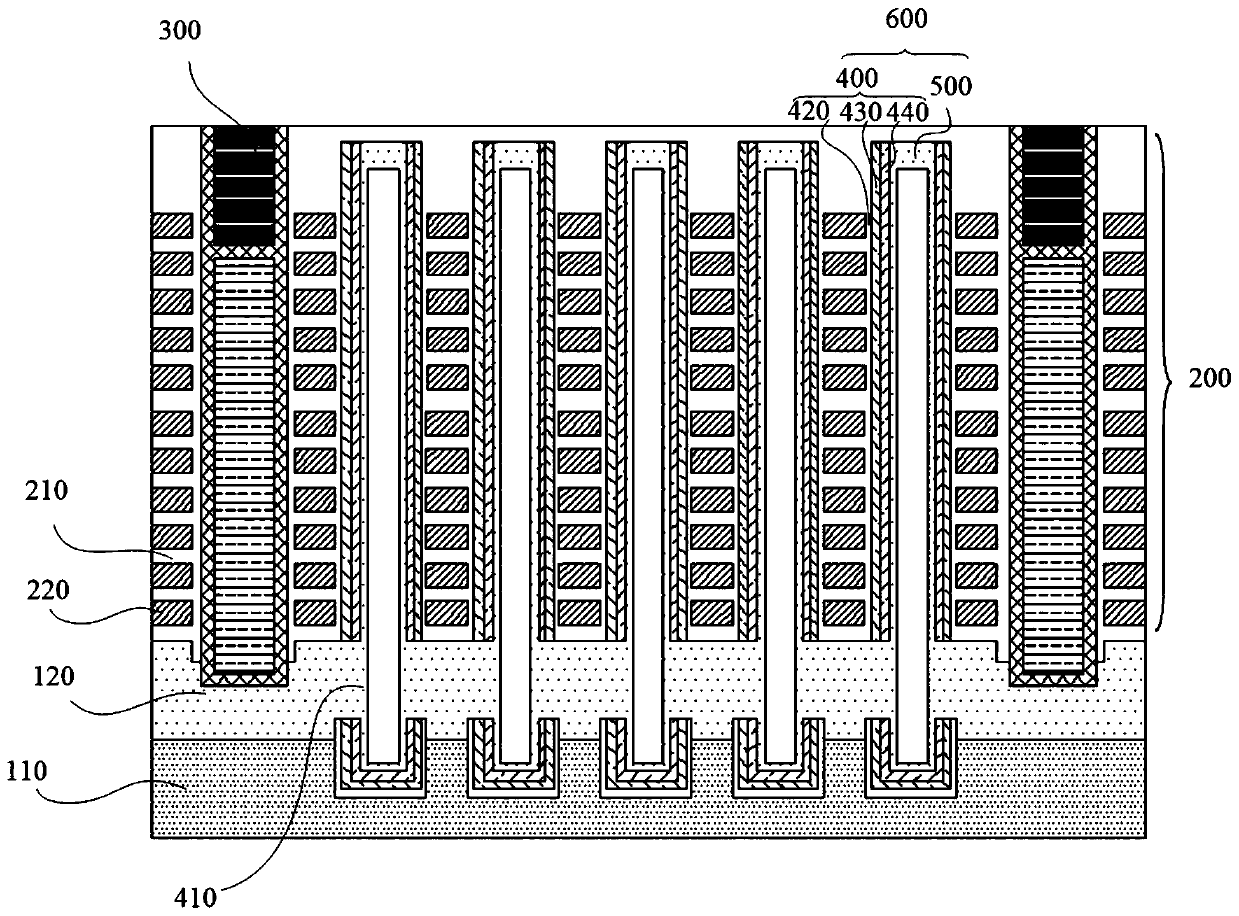

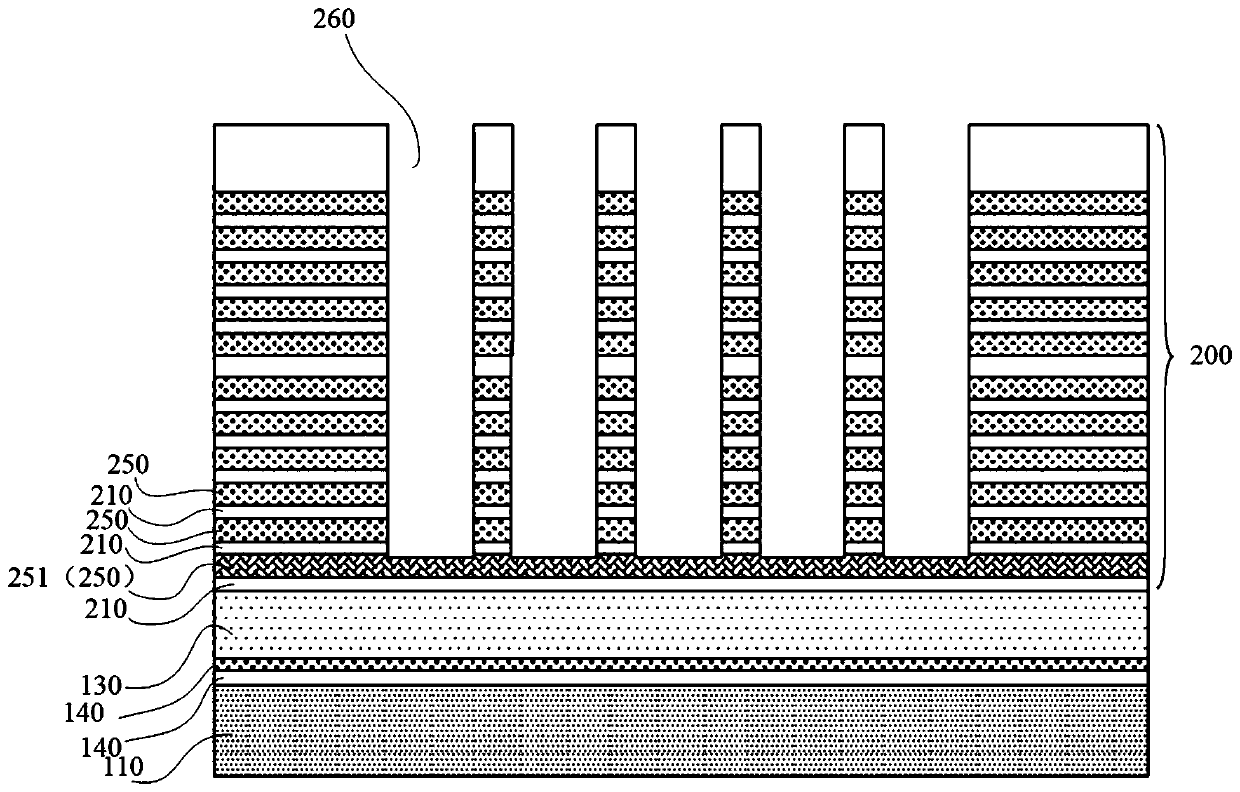

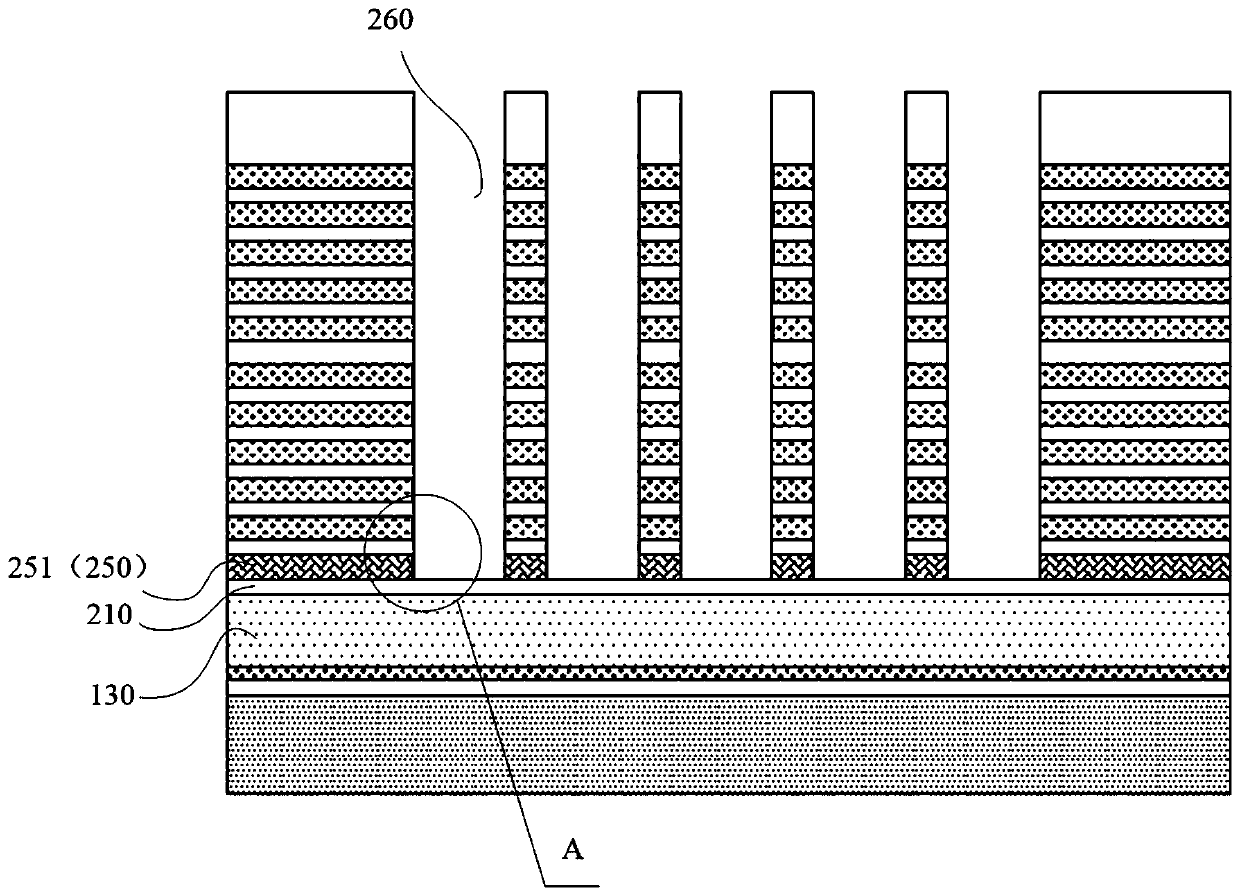

[0061] At present, in the manufacturing process of a three-dimensional memory, in order to electrically connect the channel layer in the channel hole to the common source contact in the gate slit, it is usually chosen to first provide a sacrificial layer between the stack structure and the substrate, and use The gate slit is etched so that the gate slit extends into the sacrificial layer, thereby removing the sacrificial layer and the functional layer in the sacrificial layer, and exposing the channel layer from the sidewall of the channel hole, and then passing through the stack structure and the substrate A semiconductor substrate is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com