Electric energy transmission connector and preparation method thereof

A technology of power transmission and integration, which is applied in the direction of conductive connection, contact manufacturing, and connection contact materials, etc., can solve the problems of high production cost of power transmission copper parts, increase equipment tooling cost, and not easy to automate production, so as to save processing Time, quick and easy production, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further elaborate the technical means and effects that the present invention adopts for reaching the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention are described in detail as follows:

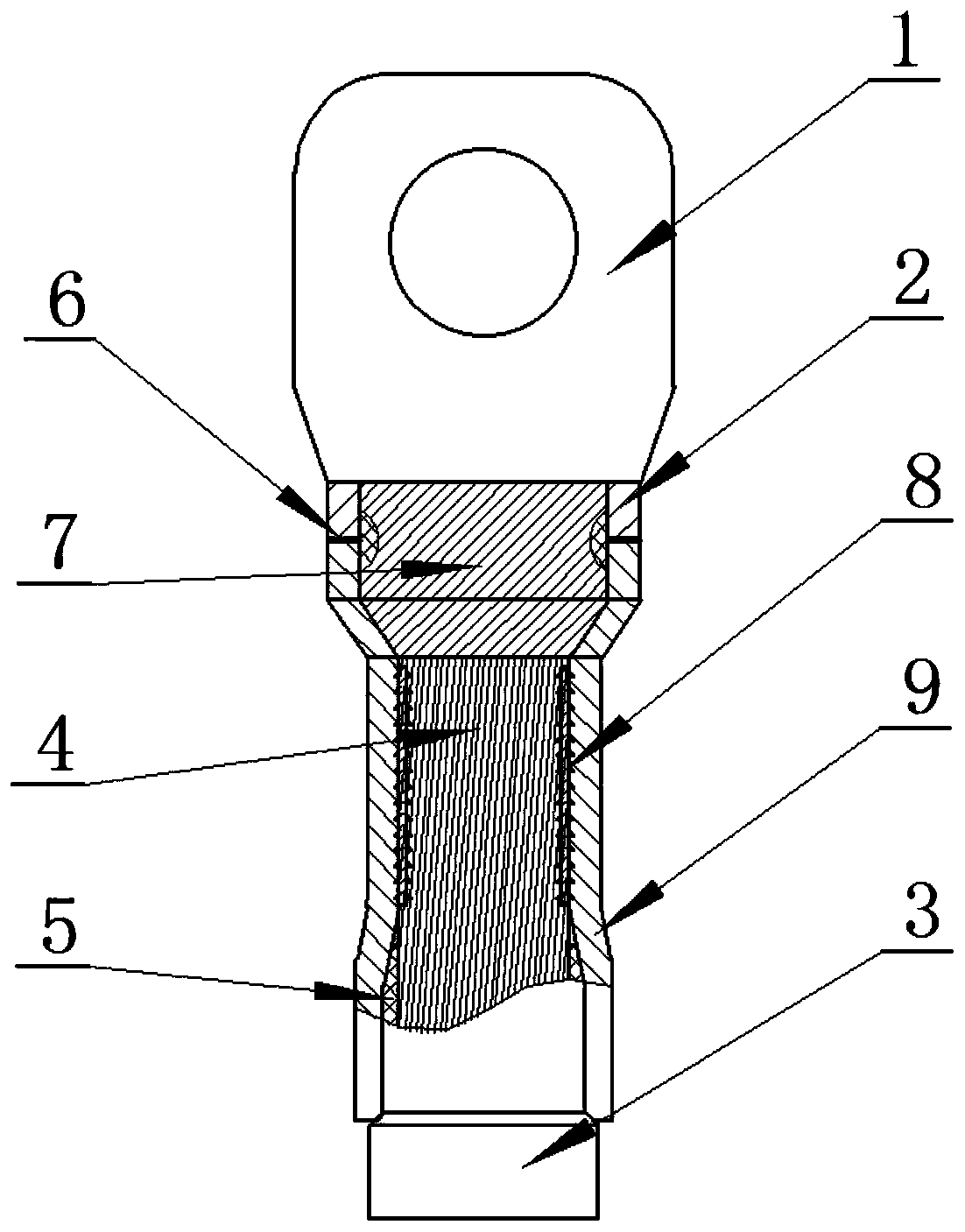

[0034] Such as figure 1 , the invention discloses a power transmission joint, which includes a power transmission copper part, a power transmission aluminum part 9 and an aluminum wire 3, the power transmission copper part includes a fixing part 1 for connecting an electrical device and a The connection part 2 of the aluminum part 9 for power transmission, the second through hole is provided inside the connection part 2, the first through hole is provided inside the aluminum part 9 for power transmission, and the insulation layer is stripped off at the front end of the aluminum wire 3 5 and then extend into the cavity formed by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com