A high-speed rice pot seedling transplanting machine seedling separating device

A technology of transplanting machine and rice, applied in the field of agricultural machinery, can solve the problems of inaccurate position of seedling tray, large space occupation, and many electric components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

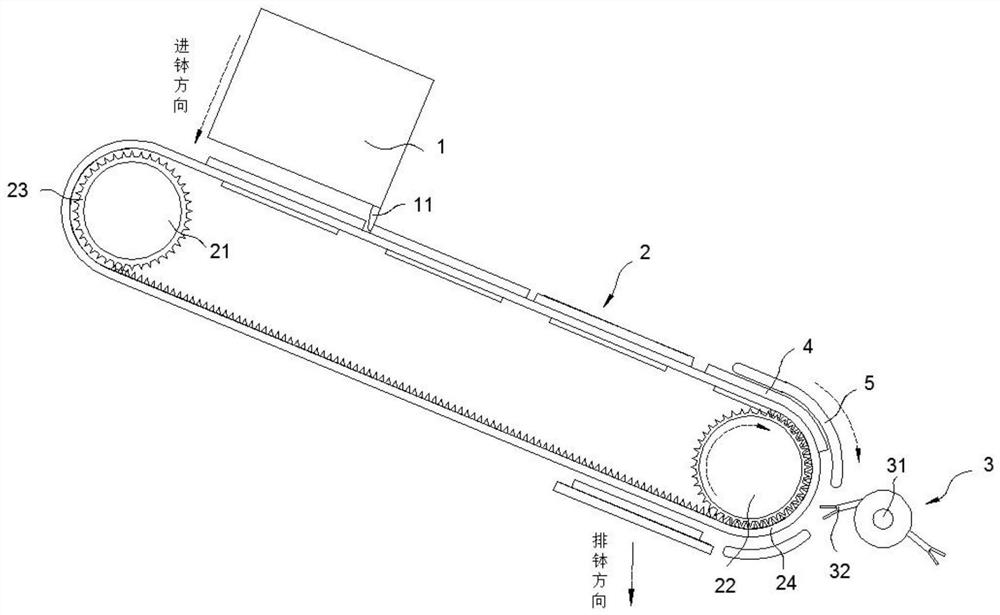

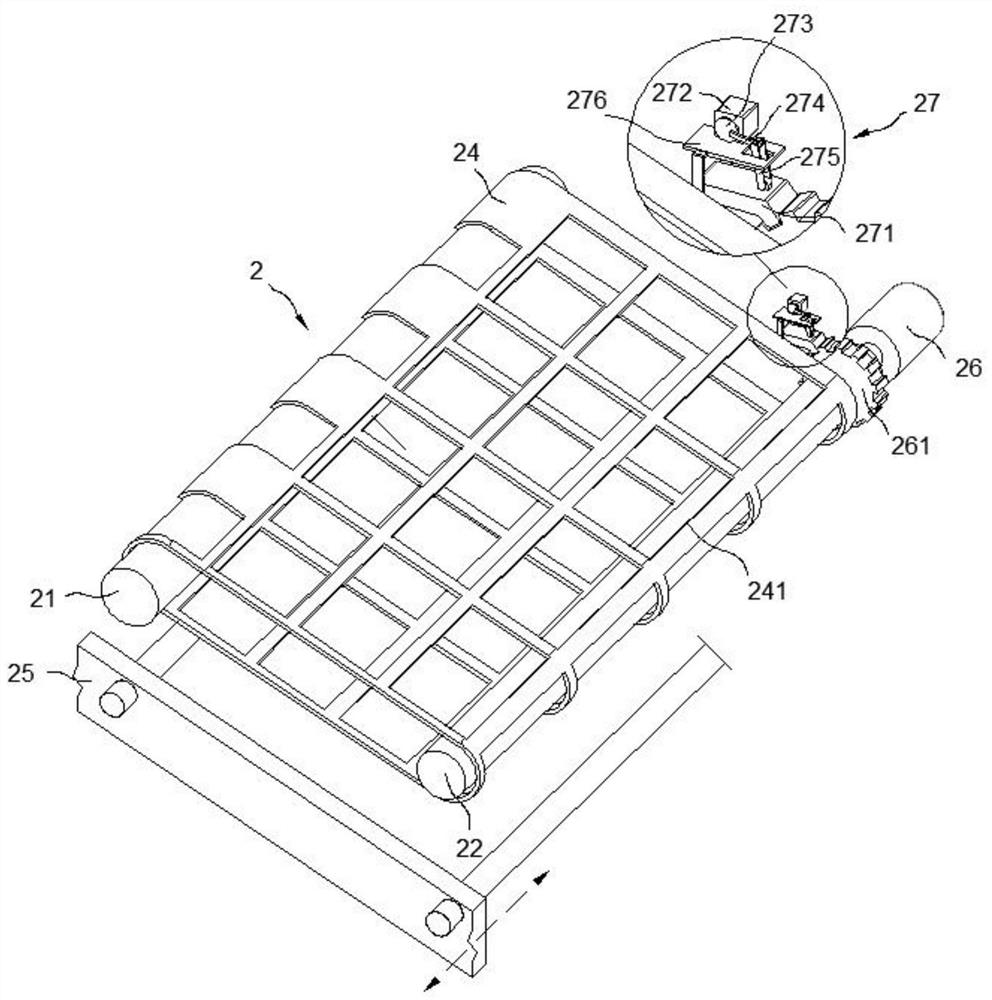

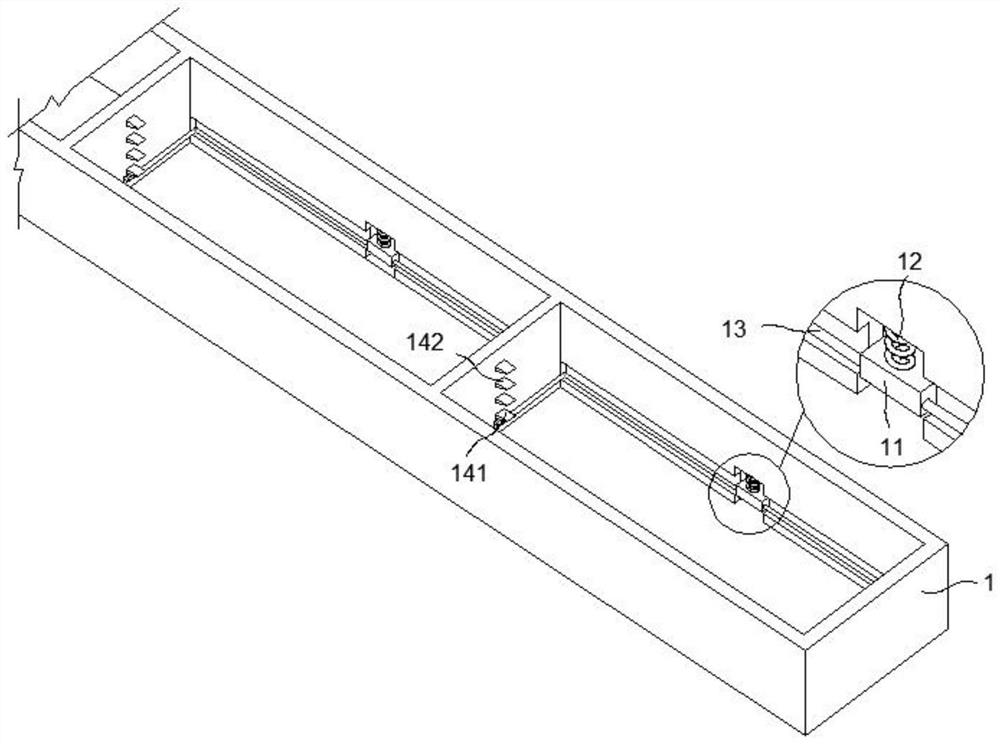

[0034] Embodiment: When using the seedling separating device, put the seedling tray 4 into the seedling tray box 1, then start the seedling tray transport mechanism 2 to transport the seedling tray 4, and use the transplanting mechanism 3 to clamp the seedlings for planting. The position-limiting effect of the assembly 27, each displacement of the carrier belt 24 is limited to the arc radius of each gear tooth, preventing the jamming phenomenon that the carrier belt 24 is repeatedly stressed and shifted when the seedlings are clamped; at the same time When a group of seedling trays 4 are used up, each group of trapezoidal blocks stretches from bottom to top after being detected by the contact block 11, so that the seedling trays 4 are fed in an orderly manner, and the seedling trays 4 are lowered sequentially, and the feeding process is stable; When the seedlings are held, the two pneumatic chucks 32 operate in sequence to make up for the intermittent time of the chucks in clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com