Preparation method and application of microporous ultrafine polymer polyurethane core material

A polyurethane and polymer technology, which is applied in the preparation and application of microporous ultrafine polymer polyurethane core materials, can solve the problems of reduced liquid absorption efficiency, easy shedding of SAP, and high rewetting, so as to reduce blocking effect and fast water absorption rate , the effect of large water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

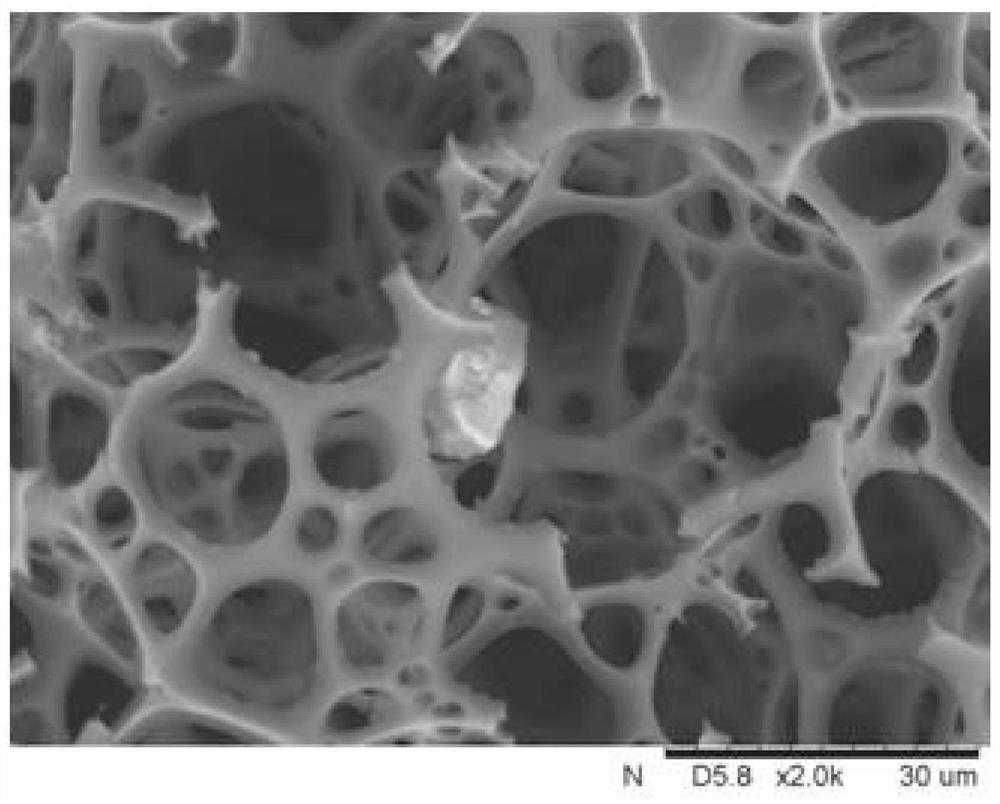

Image

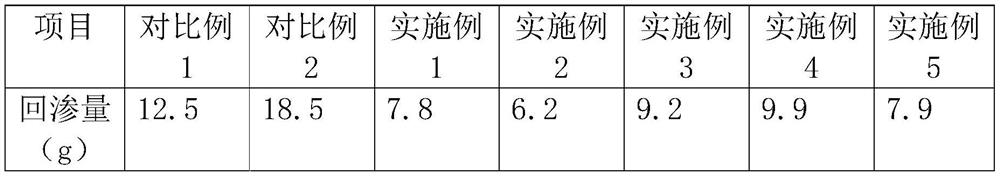

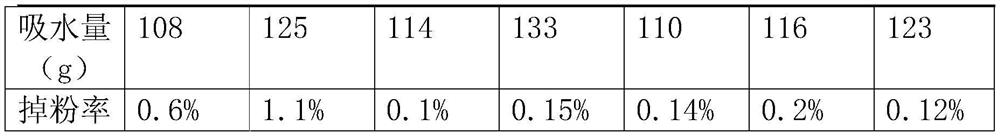

Examples

Embodiment 1

[0056] Step 1: Provide the raw material of polymer water absorbent resin, the grade is SA60N polyacrylic resin of Sumitomo Refinery, with a particle size of 230 μm, and the high molecular water absorbent resin raw material is formed by jet-type jet pulverization to form ultra-fine high-quality resin with a particle size of 45 μm. Molecular water absorbent resin.

[0057] Step 2: Prepare a microporous ultra-fine polymer polyurethane core material according to predetermined components and proportions, wherein the ultra-fine polymer water-absorbing resin accounts for 5% of the matrix, and the core material density is 83g / m 3 , 35% porosity, 3% resilience.

[0058] The components are: toluene diisocyanate, polyether polyol, stannous octoate, organosilicon oil, water, triethanolamine.

Embodiment 2

[0060] In Example 2, the ultrafine polymer water-absorbent resin accounts for 8% of the matrix, and the rest are basically the same as in Example 1;

Embodiment 3

[0062] In Example 2, the particle size of the ultrafine polymer water-absorbent resin was 75 μm, and the rest were basically the same as in Example 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com