Cooling system of partial condenser in polyamide-6 polymerization process and process thereof

A technology of cooling system and polymerization process, which is applied in the field of cooling system of part of the cooling medium of the condenser, which can solve the problems that affect the accurate control of the condensation amount of the condenser, the influence of the polymerization device on the process stability, and the heavy workload of daily operation and maintenance. Effects of equipment investment, reduction in the number of equipment, manpower and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

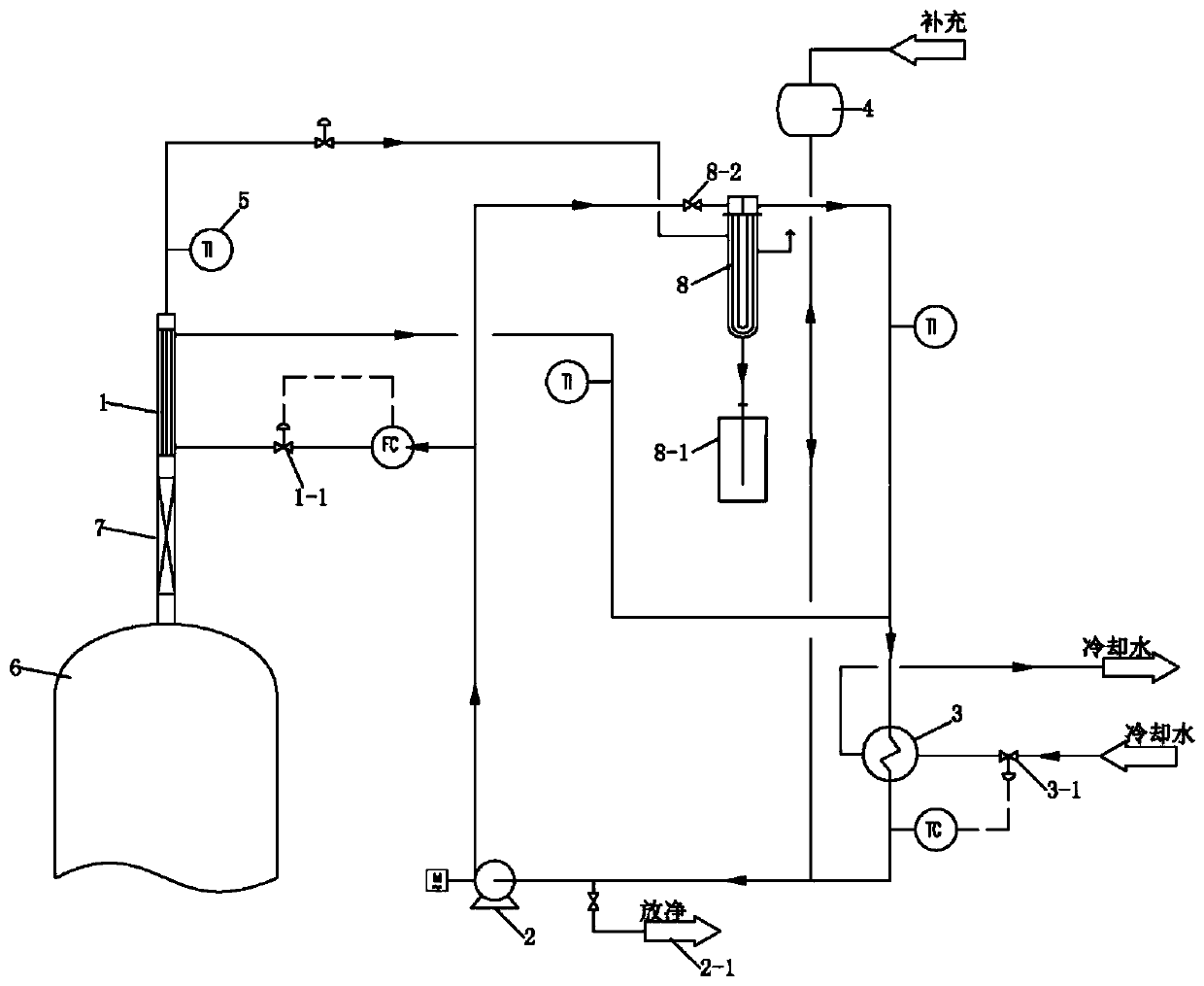

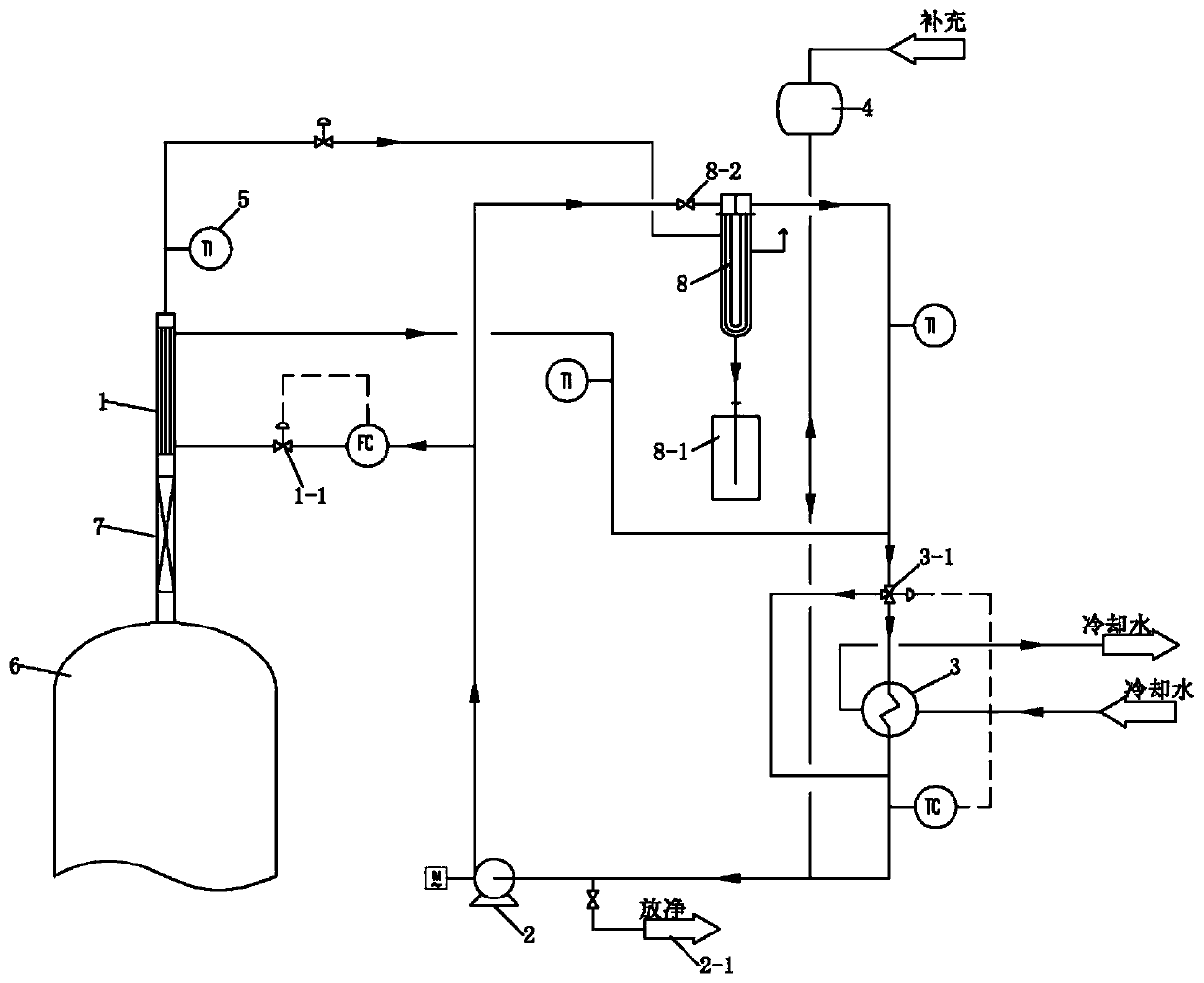

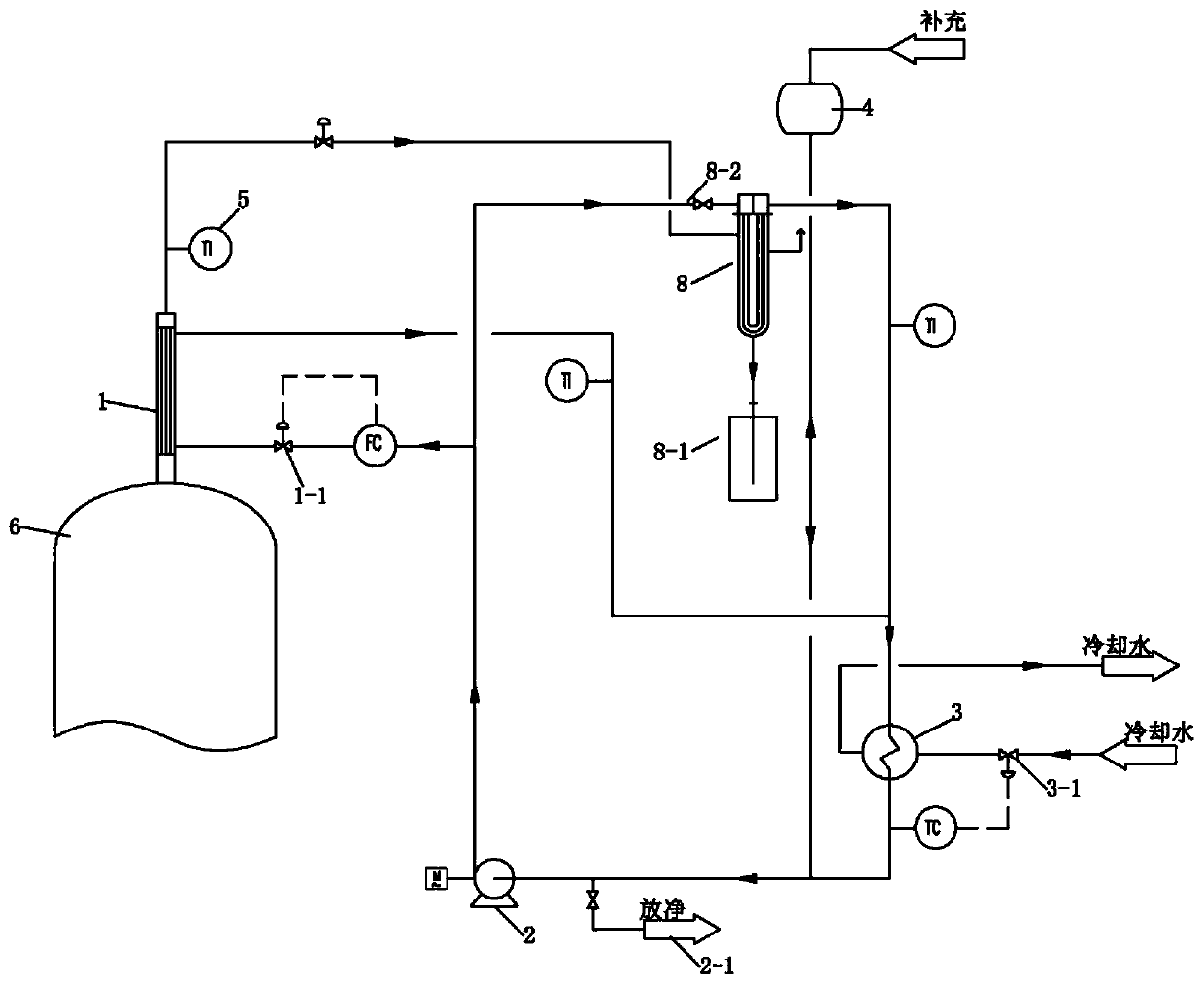

[0045] It is used in the top part condenser of single reactor 6 of nylon 6 polymerization unit ( Figure 1~3 , Figure 5~7 ).

[0046] The outlet of the circulation pump 2 is connected to the inlet of the high-boiling point cooling medium on the shell side of the partial condenser 1 through a pipeline, and the high-boiling point cooling medium outlet of the shell side of the partial condenser 1 is connected to the cooler 3 through a pipeline, and the high-boiling point cooling medium is cooled in the cooler 3 Water cooling, the outlet of the cooler 3 is connected to the inlet of the high-boiling cooling medium of the circulation pump 2 through a pipeline, forming a closed cycle of the high-boiling cooling medium; the high-boiling cooling medium outlet of the circulating pump 2 is connected to the high-boiling cooling medium of the shell side of the partial condenser 1 A flow meter and a flow regulating valve 1-1 are arranged on the pipeline between the inlets, and a three-way...

Embodiment 2

[0056] Partial condensers ( Figure 4 , Figure 8 ).

[0057] In the polyamide 6 polymerization process, when partial condensers 1 are installed at the top of cracking reactor 6, pre-polymerization reactor 6 and post-polymerization reactor 6, all partial condensers 1 can share a set of high boiling point cooling medium closed circulation cooling system . Specifically: the temperature control of the circulating pump 2, cooler 3, expansion tank 4 and cooling medium is the same as that of Embodiment 1, but in order to realize that the condensation amount of each partial condenser 1 can be controlled, it is necessary to set it separately for each cooling circuit Flow regulation, specifically involves the following:

[0058] Each partial condenser 1 high-boiling point cooling medium inlet is respectively provided with pipelines to be connected with the circulation pump 2 outlets in the above-mentioned cooling system, and flow meters and FC flow regulating valves 1-1 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com