Preparation and application method of high-strength adhesive for laminated veneer lumber

A technology of laminated veneer lumber and adhesives, which is applied in the jointing of wooden veneers, non-polymer adhesive additives, adhesives, etc., can solve the problems of affecting the working environment of workers, strong smell, high price, etc., and achieve Avoid excessive condensation, simple preparation process, and time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

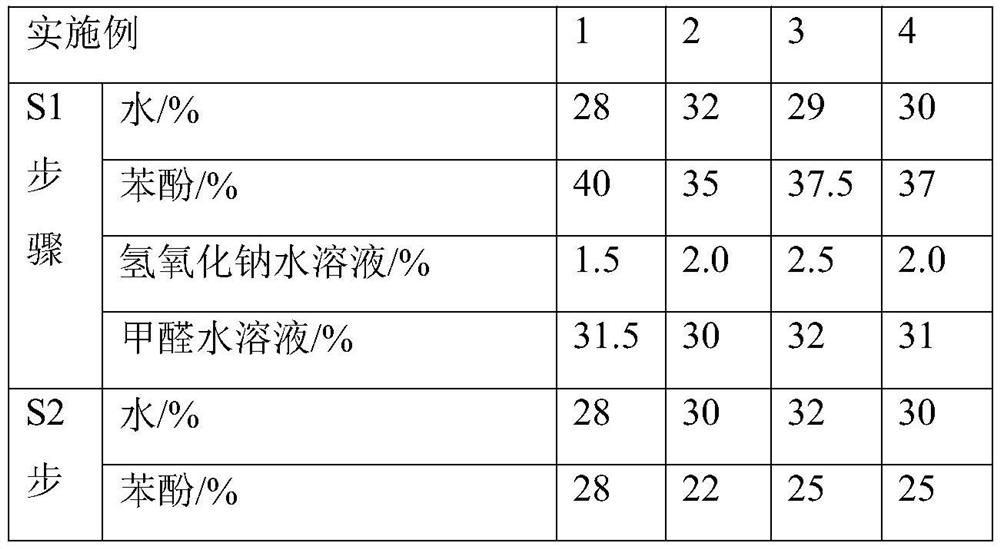

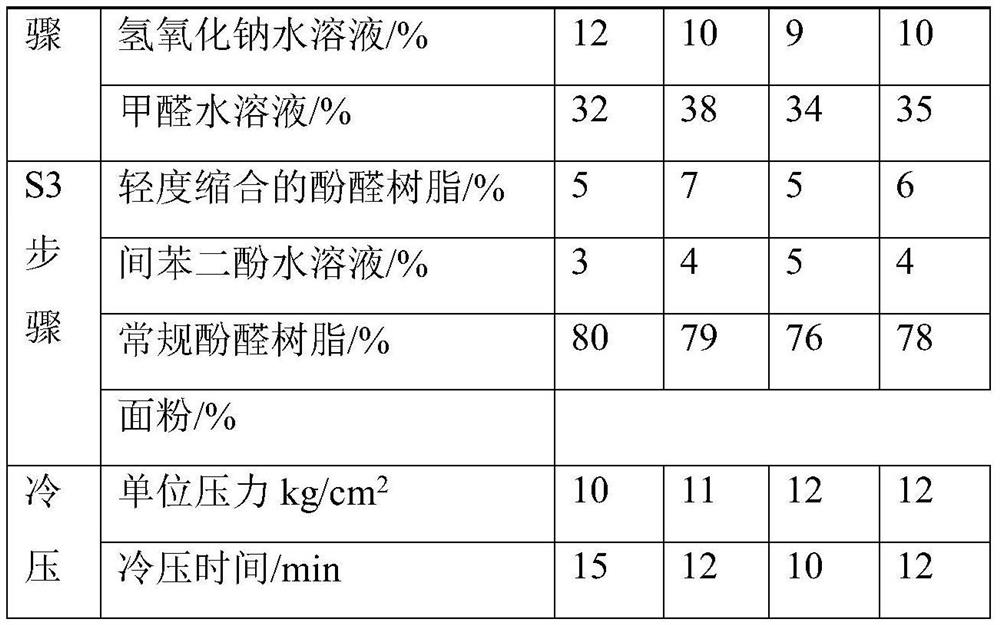

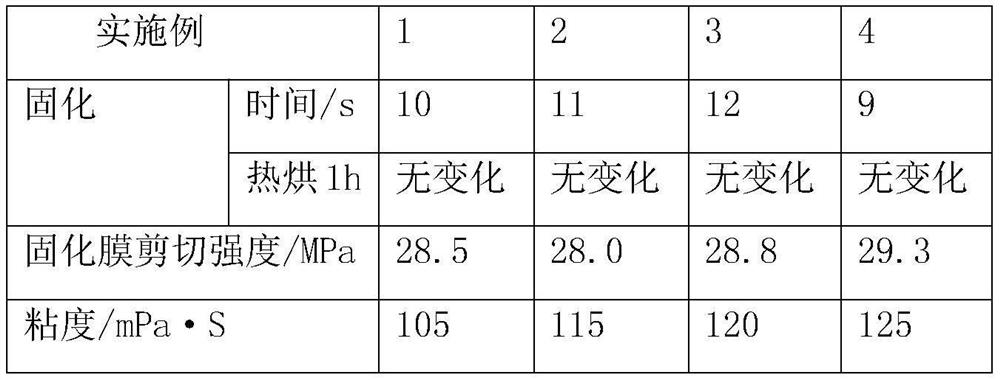

[0028] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

[0029] A preparation method for a high-strength adhesive for laminated veneer lumber, comprising the steps of:

[0030] S1 Preparation of lightly condensed phenolic resin: add water, phenol, sodium hydroxide aqueous solution and formaldehyde aqueous solution to the reaction kettle in sequence at 20-30°C, stir and react at a constant temperature of 58-62°C for 25-35min, and then heat up to 63- Stir and react at a constant temperature of 67°C for 25-35min. After reaching the cloud point, cool down to ≤30°C and discharge the material to obtain a slightly condensed phenolic resin for use;

[0031] S2 Preparation of conventional phenolic resin: Add water, phenol, sodium hydroxide aqueous solution and formaldehyde aqueous solution to the reaction kettle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com