Hardware paint spraying and drying robot

A technology of robots and hardware, applied in spray booths, spray devices, pre-treated surfaces, etc., can solve the problem that the clamping part is not sprayed, and achieve the effect of avoiding solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] see Figure 1-Figure 5 :

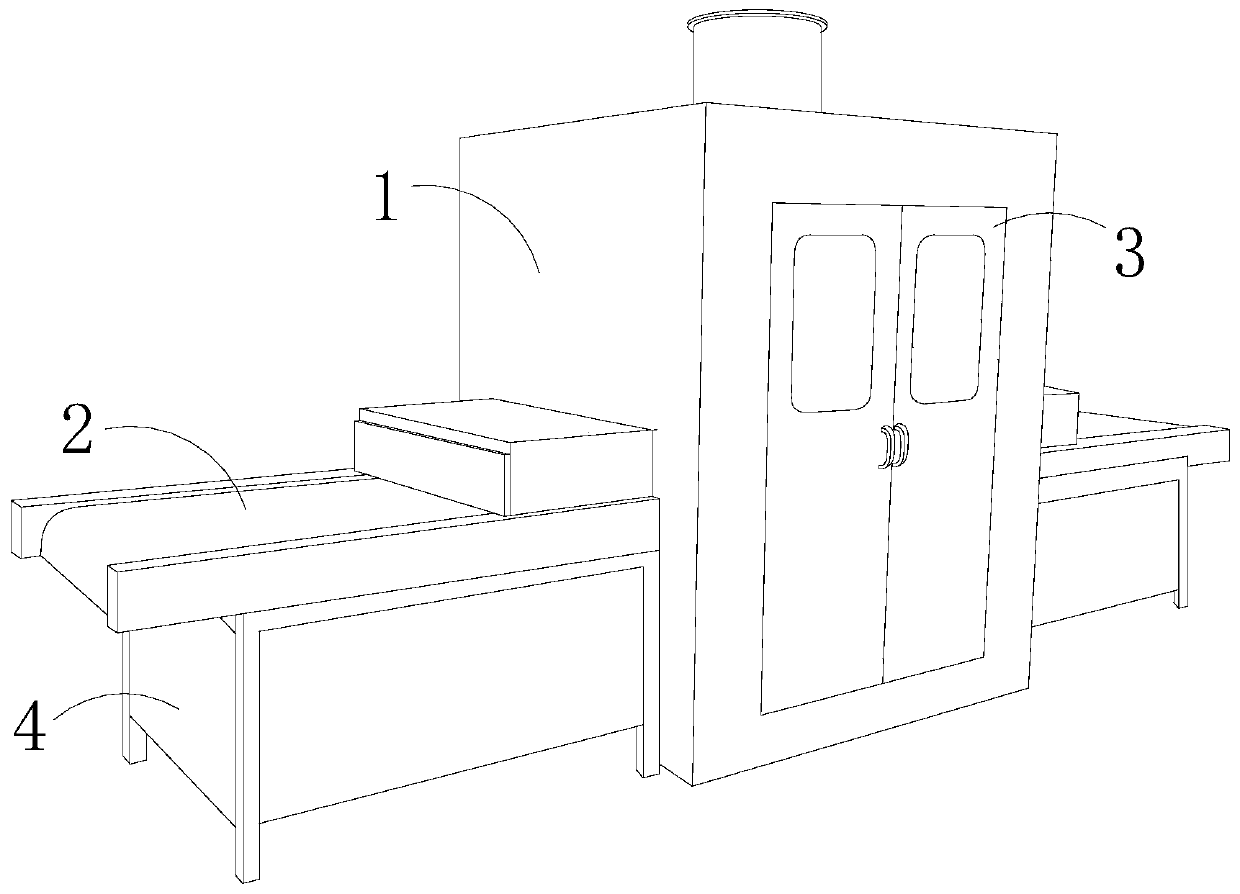

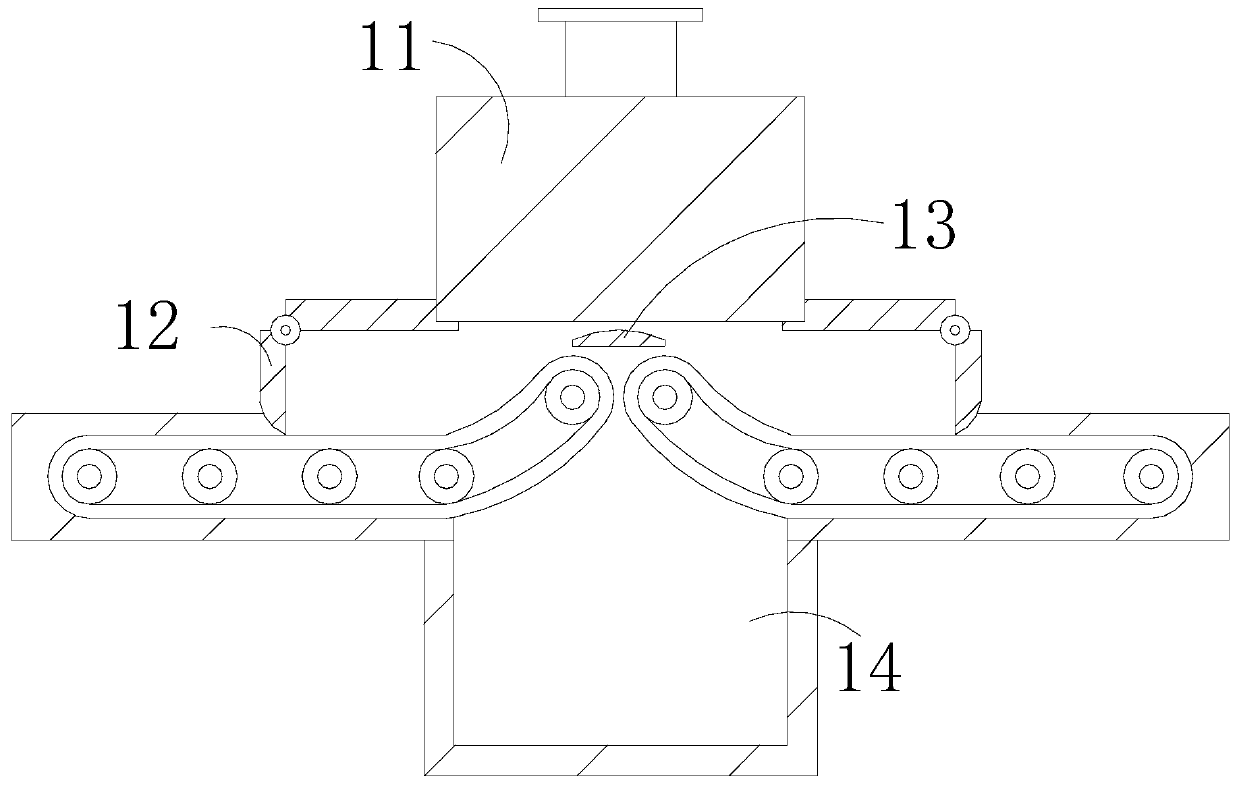

[0029] A metal spraying and drying robot, its structure includes a processing cabinet 1, a conveyor belt 2, a box door 3, and a base 4, the processing cabinet 1 is connected to the middle of the base 4 by welding, the conveyor belt 2 is installed above the base 4, and the The box door 3 is mounted on the front end of the processing cabinet 1. The processing cabinet 1 includes a paint drying chamber 11, a valve 12, a guide plate 13, and a miscellaneous storage chamber 14. The paint spray drying chamber 11 is embedded in the upper inner wall of the processing cabinet 1. The valve 12 is connected to both sides of the processing cabinet 1 through hinges, the guide plate 13 is connected to the inside of the processing cabinet 1 by welding and placed at the bottom of the paint drying chamber 11, and the miscellaneous storage chamber 14 is installed on the lower inner wall of the processing cabinet 1. The end of the conveyor belt 2 is connected to b...

Embodiment 2

[0035] see Figure 6-Figure 8 :

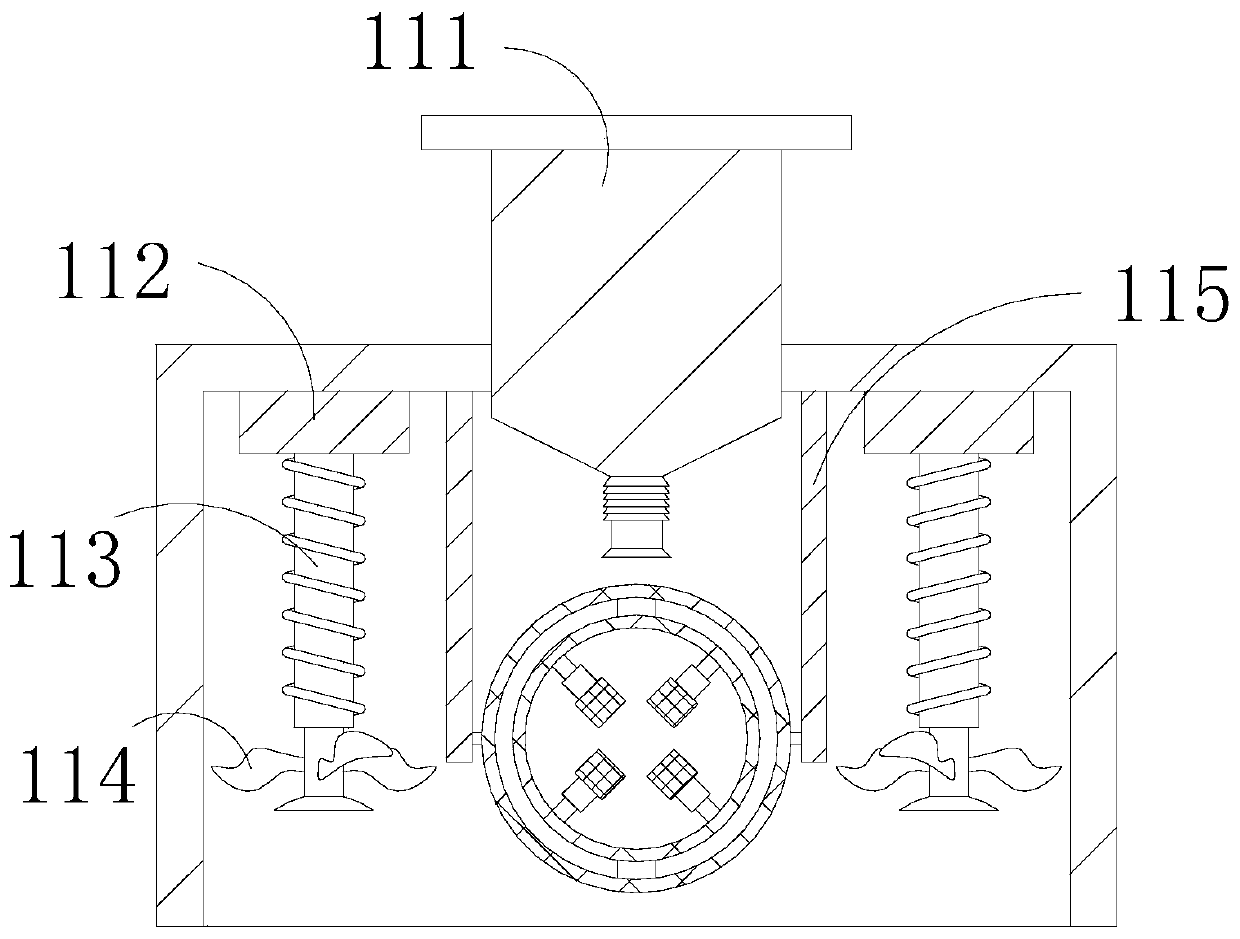

[0036]In the figure, the paint storage cylinder 111 includes an upper cover b1, a stirring paddle b2, an adjustment device b3, a lower plug b4, and a paint spray tube b5. The upper cover b1 is fitted on the upper surface of the paint storage cylinder 111. The top of b2 is connected to the bottom of the upper cover b1 by welding, the adjustment device b3 is installed at the end of the stirring paddle b2, the lower plug b4 is located below the adjustment device b3, and the paint spray pipe b5 is embedded in the bottom of the paint storage cylinder 111. The size of the lower plug b4 is matched with the inside of the paint spray pipe b5 to prevent the paint spray from solidifying inside the paint storage cylinder 111.

[0037] In the figure, the adjustment device b3 includes a concave-convex block b31, a guide rail b32, a roller b33, a support block b34, a limit plate b35, and a support rod b36. Set on the lower surface of the concave-convex blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com