Method for controlling hydraulic brake system and corresponding device

A hydraulic brake and hydraulic fluid technology, applied in the field of hydraulic brake systems, can solve problems such as not directly affecting the step-down gradient, achieve good wheel observability, reduce volume consumption, and improve braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

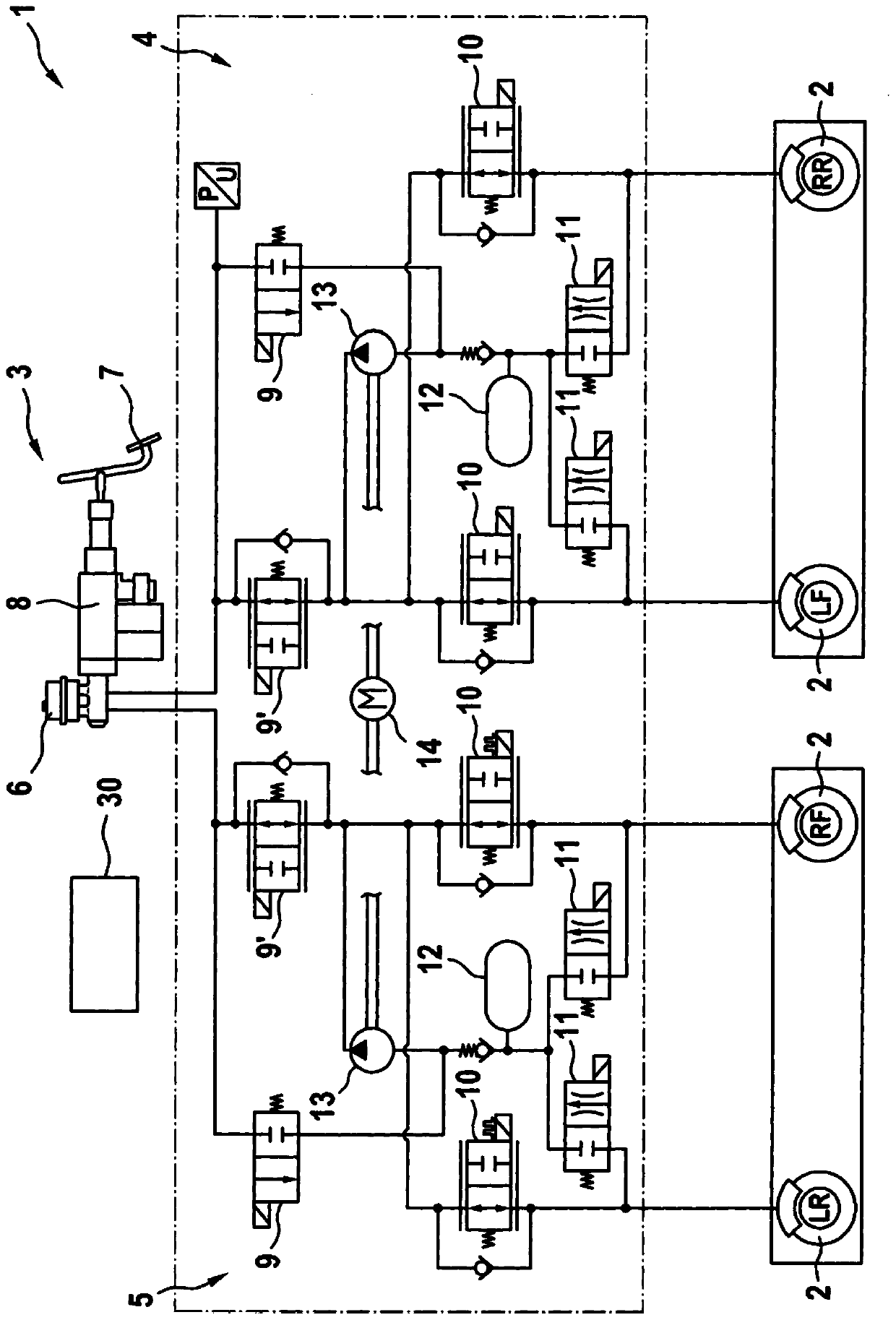

[0041] figure 1 A simplified diagram of a brake system 1 for a motor vehicle (not shown in detail) is shown. Brake system 1 has a plurality of wheel brakes 2 which can be actuated by a driver of the motor vehicle by means of a brake pedal device 3 as an actuation brake. The wheel brakes 2 are labeled LR, RF, LF and RR, thereby indicating their position or correspondence on the motor vehicle, wherein LR stands for rear left, RF stands for front right, LF stands for front left, and RR stands for rear right.

[0042] In the dotted box are the components that make up the ESP module. This is also known as the hydraulic assembly. In this example, two brake circuits 4 and 5 are formed, wherein wheel brakes LF and RR belong to brake circuit 4 and wheel brakes LR and RF belong to brake circuit 5 . The two brake circuits 4 and 5 are identically constructed, so that the structure of the two brake circuits 4 , 5 will be explained in more detail below with reference to the brake circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com