Ultrahigh-pressure water rust removal intelligent overhead vehicle

A technology of ultra-high pressure and elevated vehicles, which is applied in the direction of ships, ship cleaning devices, cleaning methods using liquids, etc. It can solve the problems of complex equipment and high cost, and achieve the effects of simple operation, high degree of automation, and safe and reliable construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

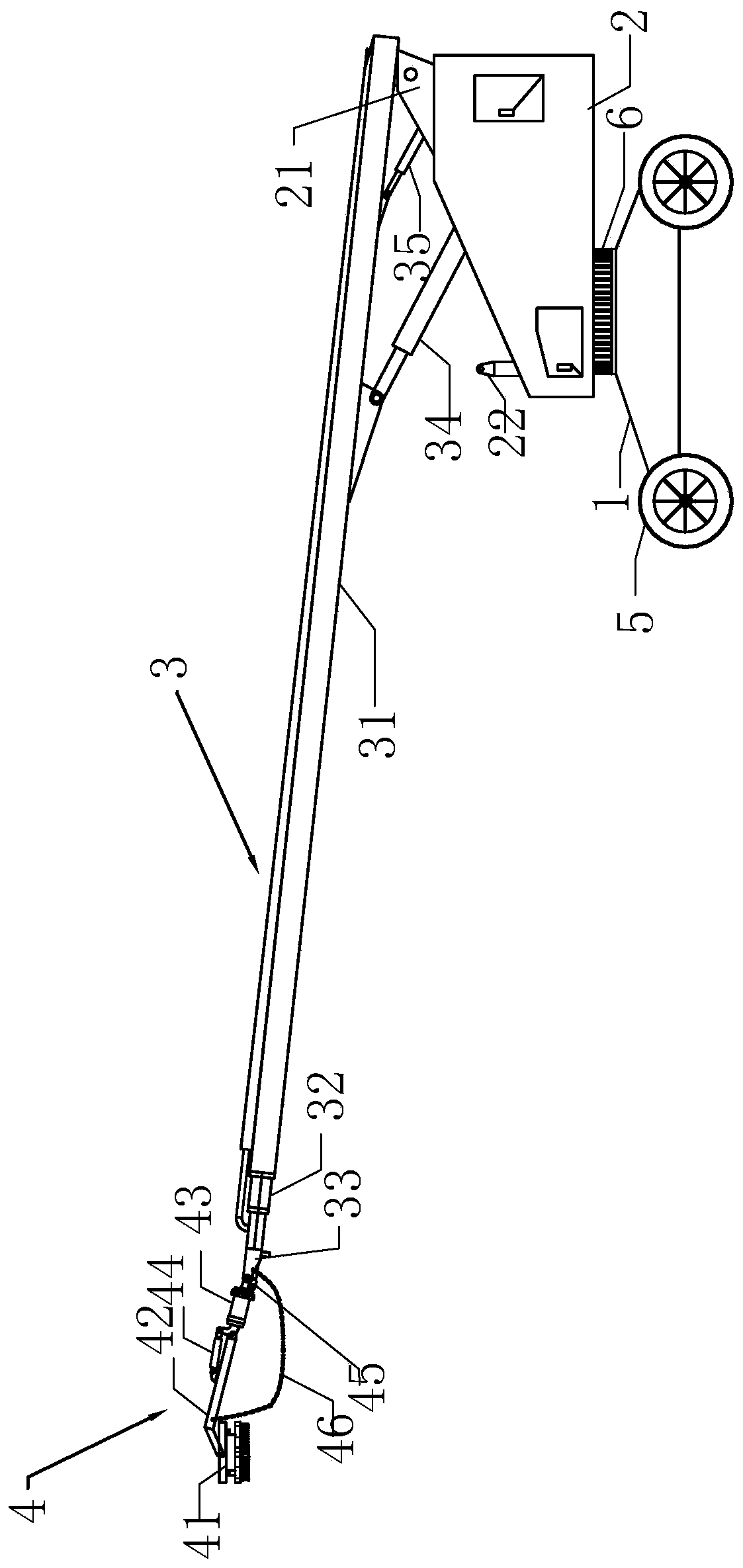

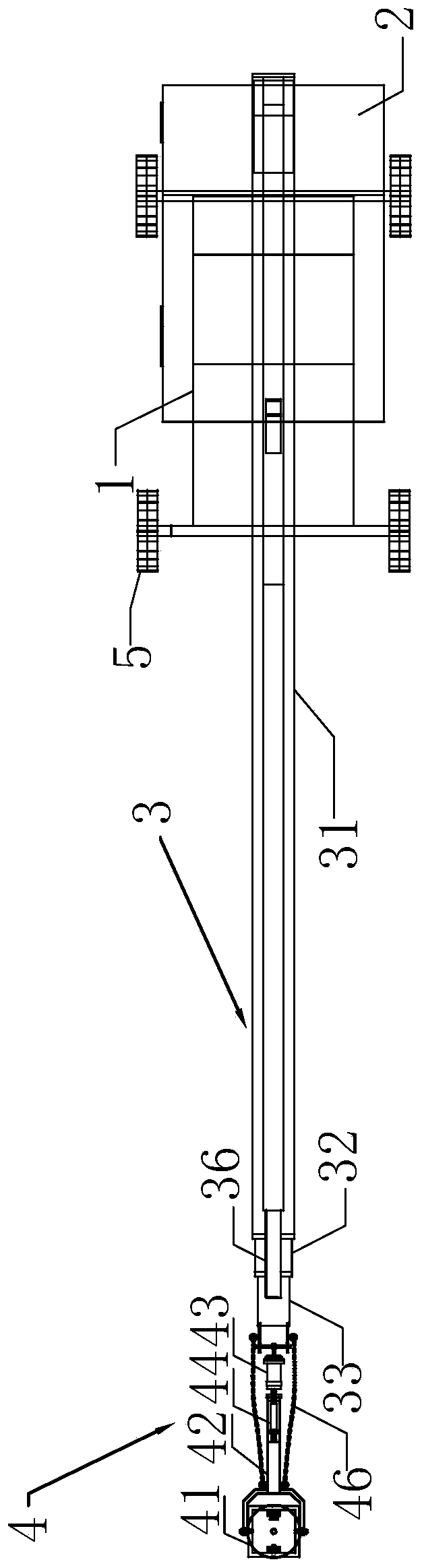

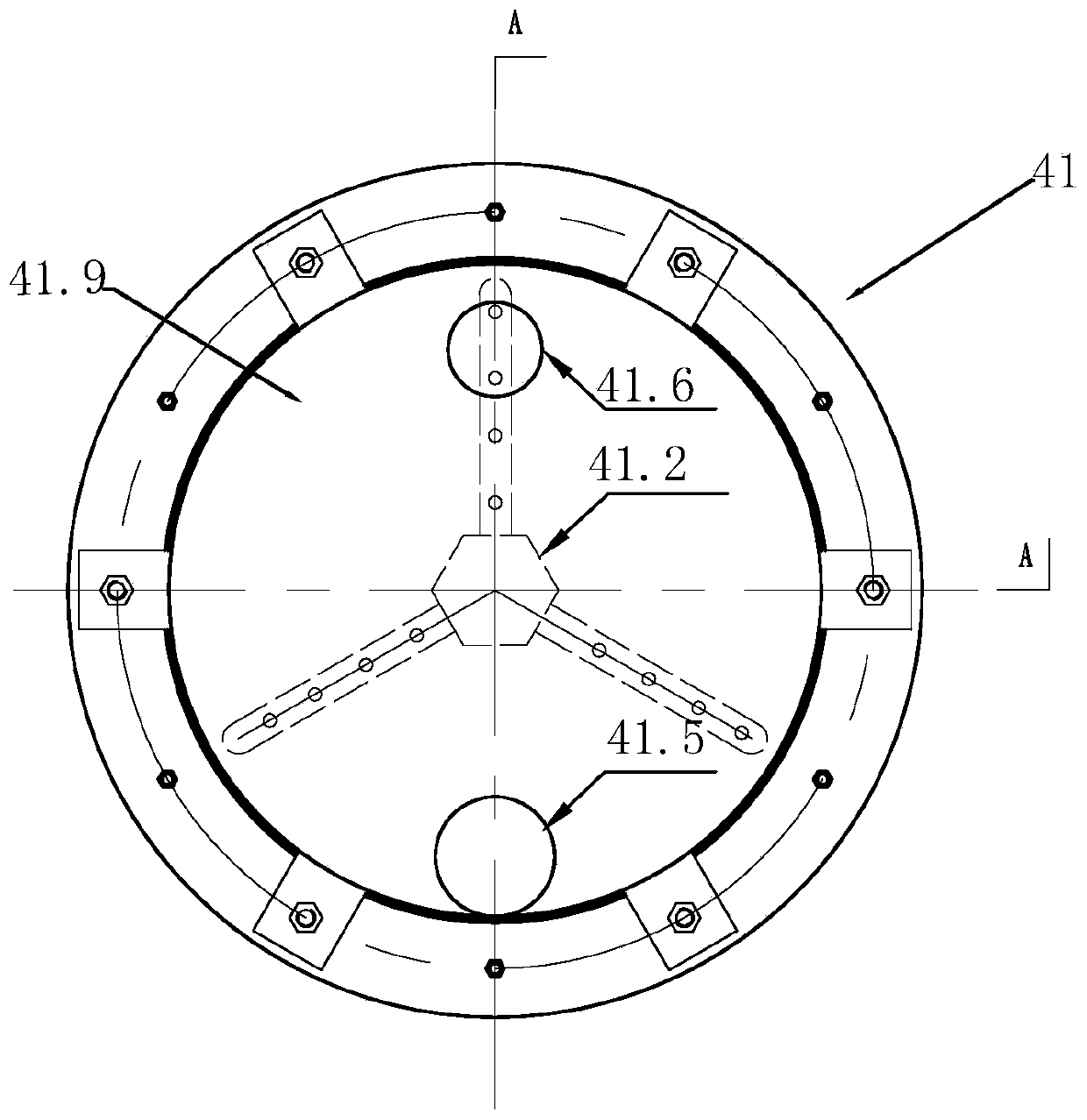

[0027] Such as figure 1 , 5 As shown, a remote-controlled ultra-high pressure water derusting intelligent elevated vehicle includes a vehicle frame 1, a chassis 2, a derusting mechanism 4, an arm telescoping mechanism 3, a traveling mechanism and a control system, and the chassis 2 is arranged above the vehicle frame 1 , the chassis 2 and the vehicle frame 1 are provided with a turntable 6 that can make the chassis 2 rotate 360°, the turntable 6 is driven by a rotating turntable motor 6A, and the boom telescopic mechanism 3 can be arranged on the upper end of the chassis 2 to rotate up and down at a certain angle. The rust mechanism 4 is detachably arranged on the upper end of the boom telescopic mechanism 3, and can rotate 360 degrees and hover at any angle position.

[0028] The specific structure is:

[0029] Boom telescopic mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com