Earth surface organic plant residue composting process and application of earth surface organic plant residue composting

A technology of plant residues and organic fertilizers, applied in the preparation of organic fertilizers, organic fertilizers, applications, etc., can solve problems such as high maintenance costs, large floor space, and adverse effects on the living environment, so as to reduce ecological restoration costs and improve The level of ecological construction and the effect of promoting resource conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

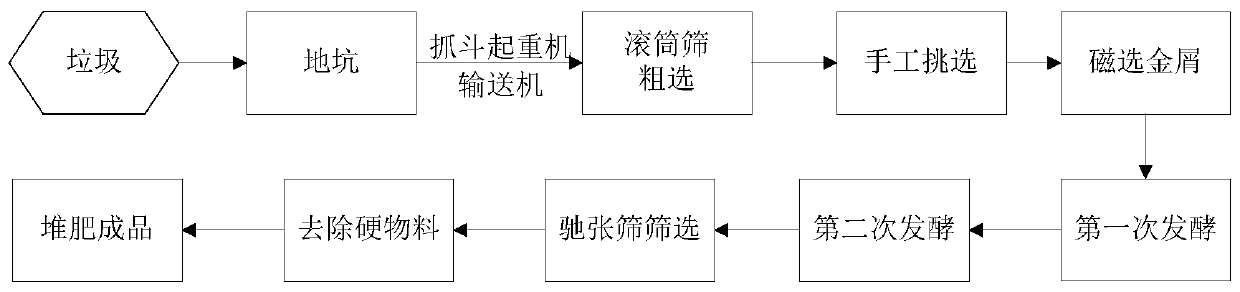

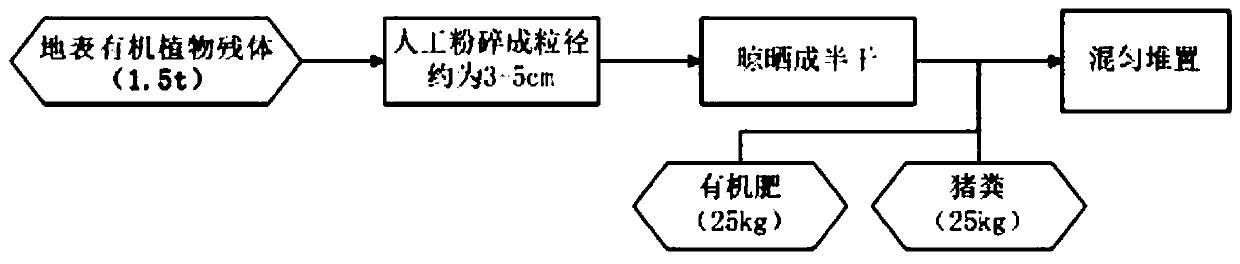

[0069] Using the organic plant residues (such as branches, leaves, shrubs, etc.) produced during the roadbed surface cleaning process as materials, after being crushed as compost raw materials, a static aerobic composting test was carried out. By monitoring the physical and chemical properties and oxygen in the composting process and greenhouse gas changes, comprehensively evaluate the composting process, and determine the appropriate composting conditions; and use the organic plant residue composting products as additive materials for slope greening planting substrates to study their effects on plant traits and soil physical and chemical properties, and then determine their use as Feasibility and generalizability of added substances.

[0070] 1. Process design of surface organic plant residue composting

[0071] The composting material adopts the surface organic residue, organic fertilizer and pig manure produced by roadbed surface cleaning as the main raw materials. The spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com