Pneumatic wear-resistant ceramic rotary slag valve

A wear-resistant ceramic and shaft technology, used in sliding valves, valve details, valve devices, etc., can solve the problems of wear of sealing rings and valve plates, affecting safe production, ash formation, etc., to achieve good sealing performance, long service life, Maintenance simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

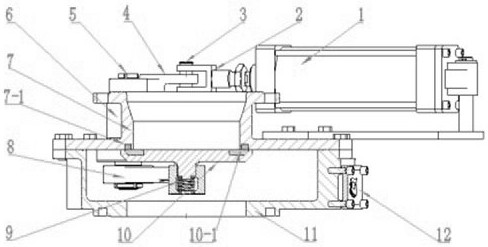

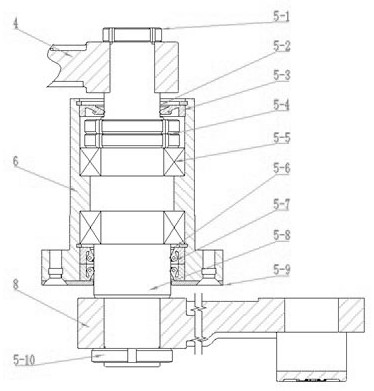

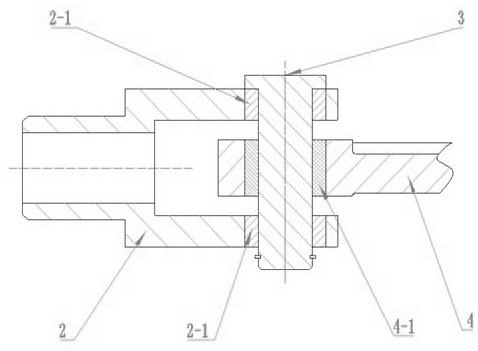

[0022] see Figure 1-3 A pneumatic wear-resistant ceramic rotary slag discharge valve shown includes a pneumatic mechanism 1, an outer rocker arm 4, a shaft assembly 5, a shaft sleeve 6, an upper valve body 7, an inner rocker arm 8, a spring seat, a valve plate 10 and a lower The valve body 11, the upper valve body 7 and the lower valve body 11 are fixed and sealed, and the pneumatic mechanism 1 is connected with the outer rocker arm 4. The preferred pneumatic mechanism 1 is installed on the outside of the upper valve body 7 through the cylinder bracket; the outer rocker arm 4 The shaft assembly 5 is connected to the inner rocker arm 8, and the inner rocker arm 8 is connected to the valve plate 10 through a spring seat. The shaft assembly 5 includes a shaft 5-8, and the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com