Tunnel step-by-step excavation simulation device

A simulation device and step-by-step technology, applied in the field of tunnel stress simulation experiments, can solve problems such as inability to simulate in reality, complicated modeling and analysis steps, and no entity in the simulation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

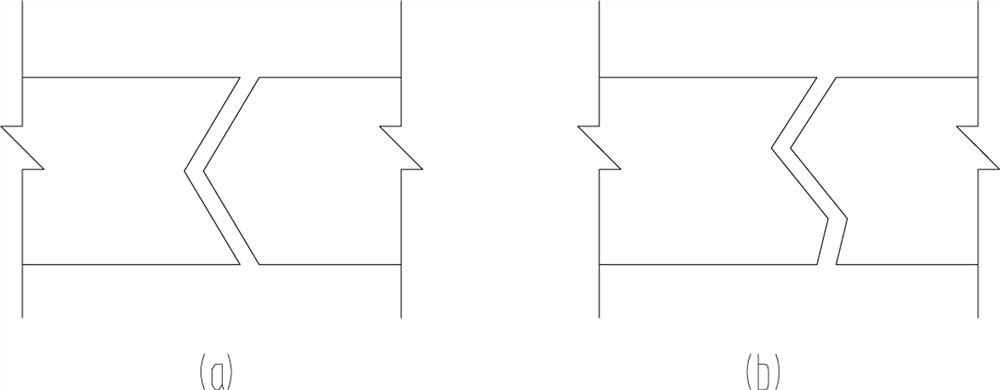

[0033] exist figure 2 Among them, (a) figure describes the "V" shape of the rock mass simulation block 2; (b) figure describes the "Z" shape of the rock mass simulation block 2; The linear rock mass simulation block 2, the rock mass simulation block 2 designed with the above two chimeric shapes has a good limit ability when it is in contact with each other, which greatly improves the stability of the overall structure; when pouring the rock mass simulation block 2, one or both of the fitting methods can be selected to prefabricate the pouring formwork of the rock mass simulation block 2.

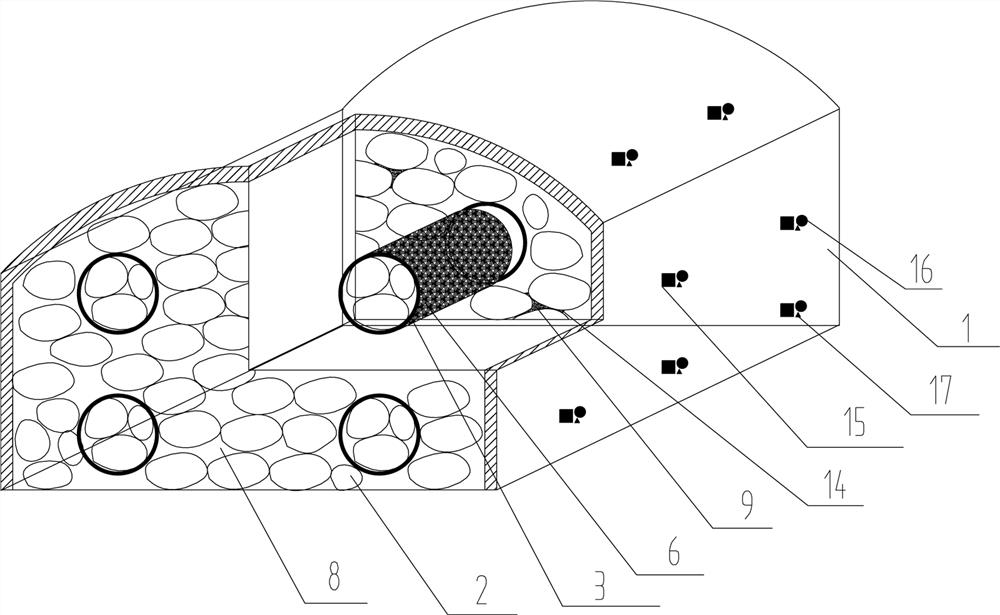

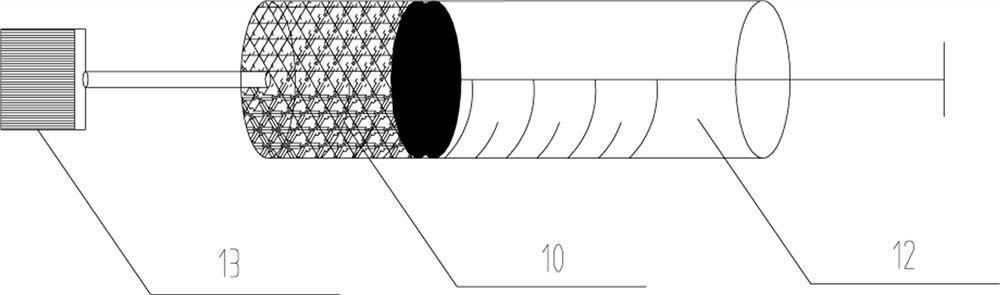

[0034] Combine below Figure 1~Figure 3 Embodiments of the present invention will be further described.

[0035] A step-by-step excavation simulation device for tunnels, including a simulated tunnel 1 made of tempered glass, inside the simulated tunnel 1 is arranged a "V"-shaped fitting and " Z"-shaped rock mass simulation block 2 that fits and cooperates with each other; at the same time,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com