Stretchable transient wire and preparation method thereof

A wire and transient technology, applied in the field of preparation of composite films based on silver microsheets and gelatin, can solve the problems of high processing cost and long dissolution time, and achieve a product that can withstand external stress, simple processing technology, and controllable dissolution speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

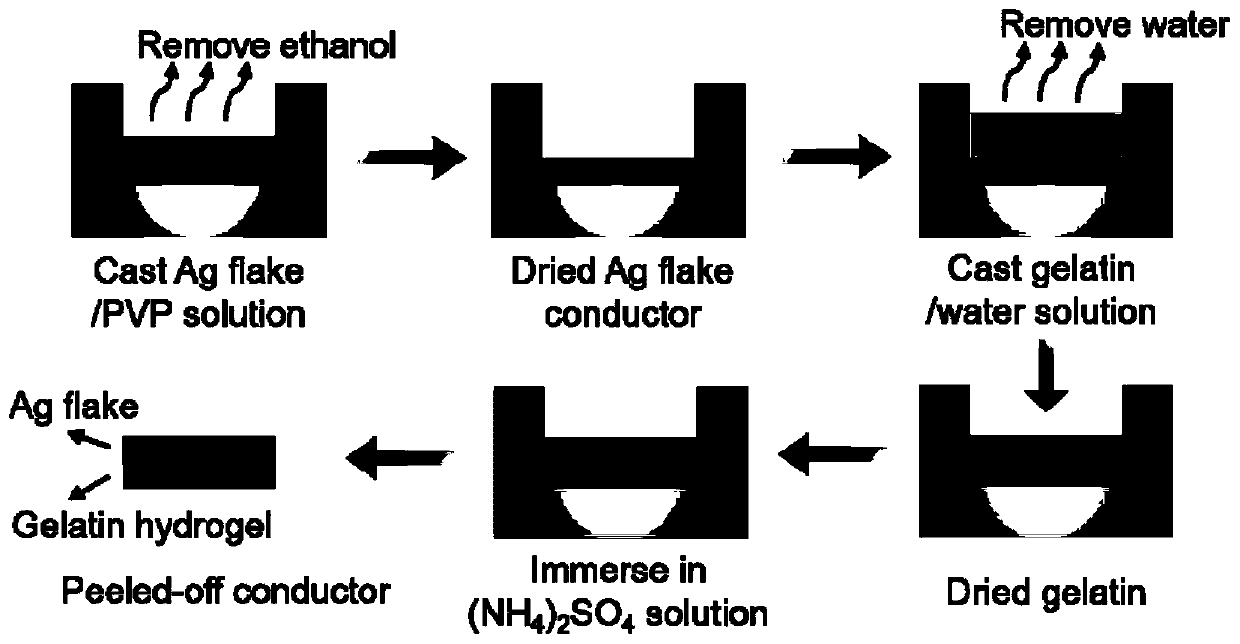

Method used

Image

Examples

Embodiment 2

[0023] In this example, the polyvinylpyrrolidone solution with a mass fraction of 20% is blended with the silver microflake powder at a mass ratio of 5:1, and the other procedures are consistent with those in Example 1.

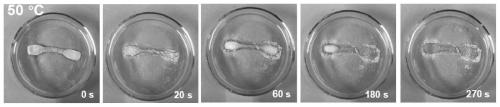

[0024] The transient wire prepared in this example was placed in an aqueous solution at 60°C as Figure 4 As shown, due to the higher temperature and the higher content of polyvinylpyrrolidone, the dissolution rate is accelerated, and the transient wire has been decomposed in about 2 minutes and the gelatin is completely dissolved in water.

Embodiment 3

[0026] In this example, the polyvinylpyrrolidone solution with a mass fraction of 20% was blended with the silver microflake powder at a mass ratio of 15:7, and the other procedures were consistent with those in Example 1.

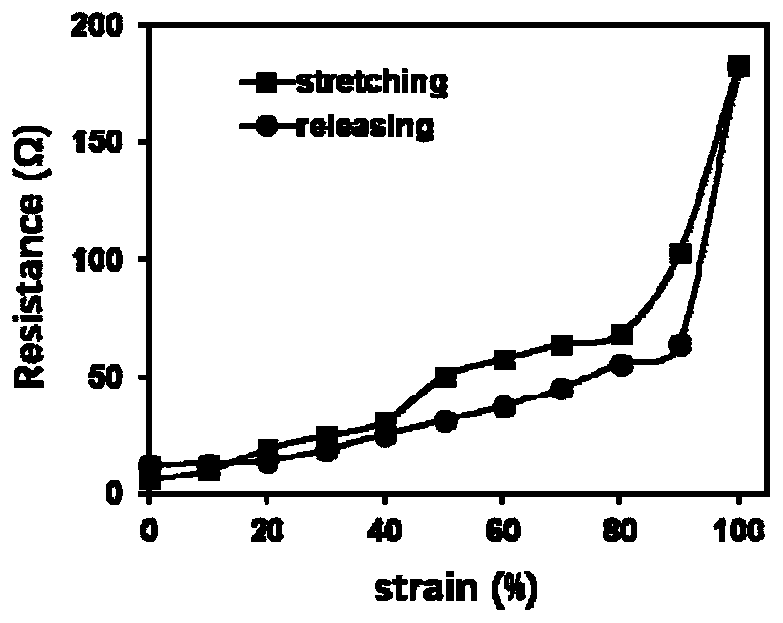

[0027] The transient wire in this example is clamped on the clamp of the stretching rod, the stretching speed is set to 1.25mm / s, the maximum stretching strain is set to 20%, 30% and 50% respectively, and 100 cycles of stretching are carried out. Stretch / release, the change in resistance when the strain reaches 0% after each cycle is as Figure 5 shown. This embodiment has excellent electrical conductivity (R=4Ω), and after 100 cycles of stretching / releasing at 50% stress, the resistance only doubles, showing excellent stability under external stress.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com