A kind of instant water-soluble starch film-forming composition

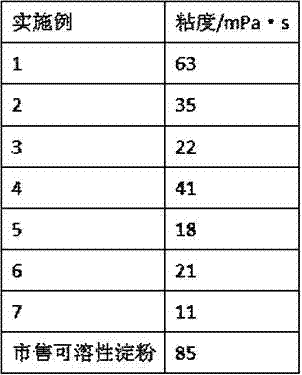

A composition and starch technology, applied in the field of starch derivatives, can solve the problems of limited application, undisclosed dissolution time, etc., and achieve the effects of rapid disintegration, controllable dissolution speed, and controllable viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

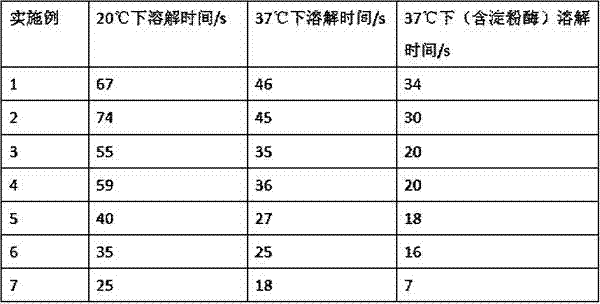

Examples

Embodiment 1

[0032] Low degraded starch 100kg

[0033] Macrogol 4000 1g

[0034] Make 1 g of polyethylene glycol 4000 into 1 L of aqueous solution. The low-degradation starch is put into a high-speed mixer, and the polyethylene glycol 4000 aqueous solution is added in portions under stirring, and stirred for at least 3 hours to obtain the product.

Embodiment 2

[0036] Low degraded starch 100kg

[0037] Polyacrylic acid 10g

[0038] The low-degradation starch and polyacrylic acid are respectively prepared into solutions, wherein the mass concentration of the low-degradation starch solution is 10%, and the polyacrylic acid solution is 0.1%, and the two are mixed with a sprayer and dried.

Embodiment 3

[0040] Hydroxypropyl starch 100kg / h (feed speed)

[0041] Polyethylene glycol 4000 50g / h (feed rate)

[0042] step

[0043] The parameters of the extruder are: the length-to-diameter ratio of the screw is 15:1, the rotation speed is 200rpm, the temperatures of the inlet and outlet and each slider are respectively:

[0044] Feed inlet: room temperature,

[0045] Slider 1: 60°C

[0046] Slider 2: 90°C

[0047] Slider 3: 140°C

[0048] Slider 4: 150°C

[0049] Slider 5: 145°C

[0050] Slider 6: 130°C

[0051] Outlet: 80°C.

[0052] Put the hydroxypropyl starch into the hopper of the extruder, start the extruder, the material enters the barrel under the drive of the screw, pour pure water into the extruder on the second slider, and connect the third slider to polyethylene Alcohol 4000 feeder, the fifth slider connected to vacuum for exhaust. The material is extruded into long strips through a die, and cut into pellets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com