Optical lens group, camera module and terminal

An optical mirror and optical system technology, applied in optics, optical components, instruments, etc., can solve problems such as inability to accurately control the air gap, low imaging quality of the camera lens, and difficulty in grasping the size of the edge area, so as to reduce poor imaging performance , Improve stability and reliability, and reduce production cost loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

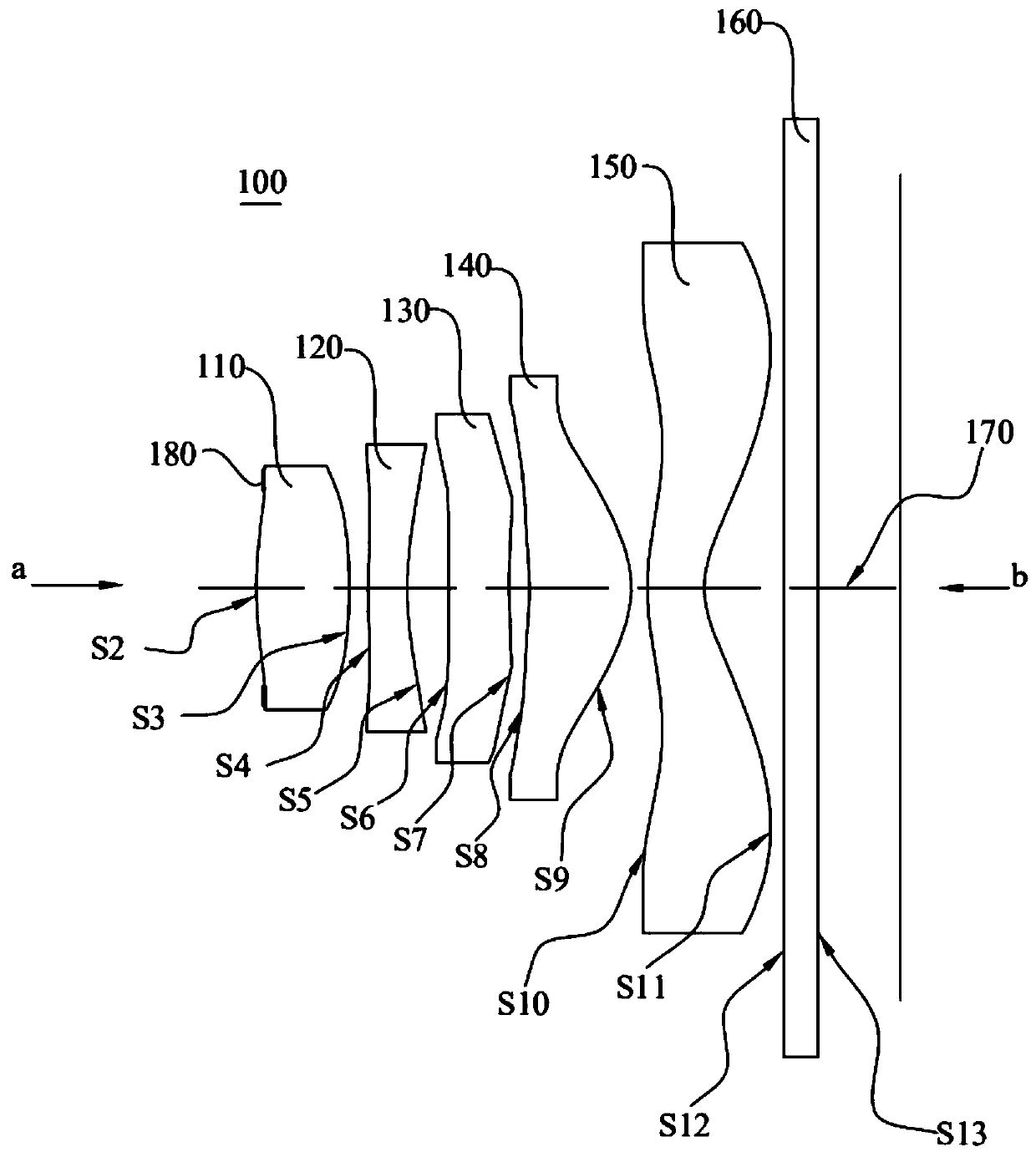

[0101] For a schematic structural diagram of the imaging optical mirror group 100 of the embodiment of the present application, see figure 1 , the optical lens group 100 includes a diaphragm 180 (attached to the object side of the first lens 110 ), a first lens 110 , a second lens 120 , and a third lens 130 arranged in sequence from the object plane a to the image plane b along the optical axis 170 , the fourth lens 140, the fifth lens 150 and the infrared filter 160.

[0102] The first lens 110 has a positive refractive power, the object side of the first lens 110 at the optical axis 170 is a convex surface, and the image side of the first lens 110 at the optical axis 170 is a convex surface. The object side of the first lens 110 at the circumference is convex, and the image side of the first lens 110 at the circumference is convex.

[0103] The second lens 120 has a negative refractive power, the object side of the second lens 120 at the optical axis 170 is convex, and the ...

Embodiment 2

[0130] For a schematic structural diagram of the imaging optical mirror group 100 of the embodiment of the present application, see Figure 5 , the optical lens group 100 includes a diaphragm 180 (attached to the object side of the first lens 110 ), a first lens 110 , a second lens 120 , and a third lens 130 arranged in sequence from the object plane a to the image plane b along the optical axis 170 , the fourth lens 140, the fifth lens 150 and the infrared filter 160.

[0131] The first lens 110 has a positive refractive power, the object side of the first lens 110 at the optical axis 170 is a convex surface, and the image side of the first lens 110 at the optical axis 170 is a convex surface. The object side of the first lens 110 at the circumference is convex, and the image side of the first lens 110 at the circumference is convex.

[0132] The second lens 120 has a negative refractive power, the object side of the second lens 120 at the optical axis 170 is convex, and the...

Embodiment 3

[0159] For a schematic structural diagram of the imaging optical mirror group 100 of the embodiment of the present application, see Figure 9 , the optical lens group 100 includes a stop 180 (attached to the object side of the first lens 110 ), a first lens 110 , a second lens 120 , and a third lens 130 arranged in sequence from the object plane a to the image plane b along the optical axis 170 , the fourth lens 140, the fifth lens 150 and the infrared filter 160.

[0160] The first lens 110 has a positive refractive power, the object side of the first lens 110 at the optical axis 170 is a convex surface, and the image side of the first lens 110 at the optical axis 170 is a concave surface. The object side of the first lens 110 at the circumference is convex, and the image side of the first lens 110 at the circumference is convex.

[0161] The second lens 120 has a negative refractive power, the object side of the second lens 120 at the optical axis 170 is convex, and the ima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com