Coordinated control method for vehicle roll and ride comfort

A coordinated control, vehicle-side technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of difficult to provide anti-rolling force, low telescopic speed, low damping force, etc., and achieve simple structure, Reduced energy consumption and wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

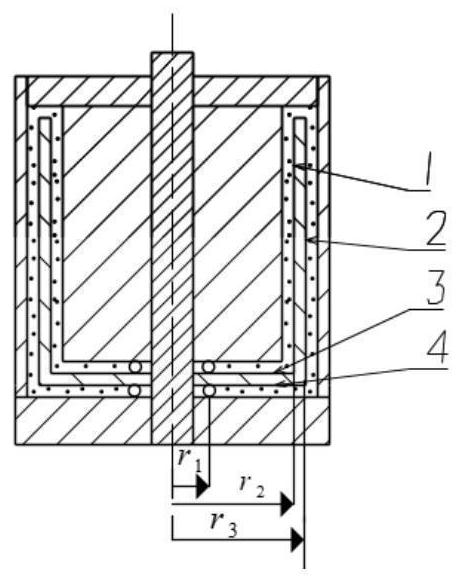

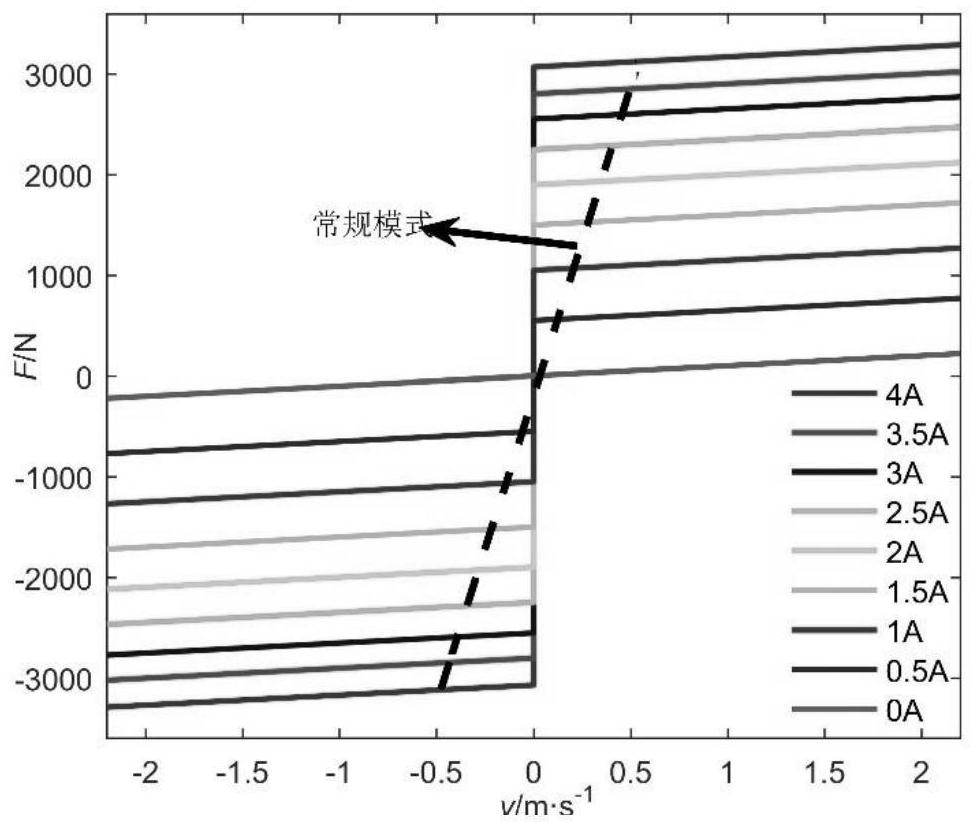

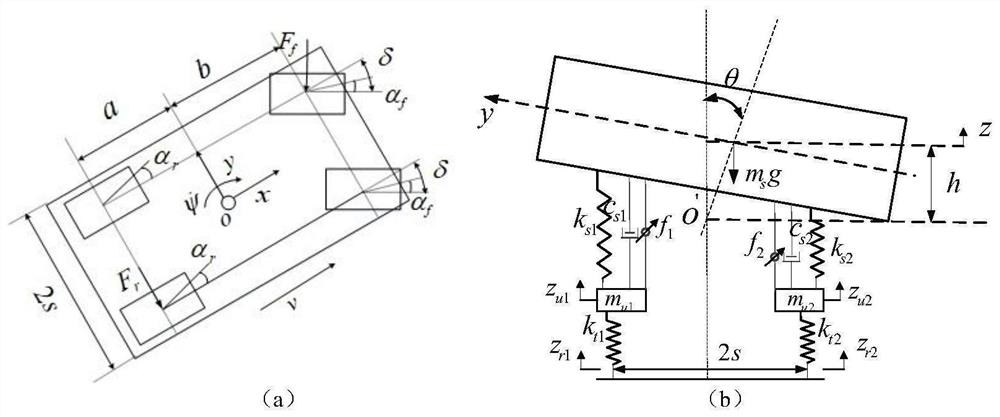

[0089] The present invention adopts the shear mode magneto-rheological shock absorber as the actuator for the coordinated control of vehicle roll and ride comfort. Taking a car with independent front and rear axles as an example, the four shock absorbers of the car suspension are replaced by This kind of shear mode magnetorheological shock absorber. This kind of magnetorheological shock absorber works in shear mode. Under the action of an external magnetic field, the magnetorheological fluid in the magnetorheological shock absorber exhibits obvious Binghim plastic fluid characteristics, that is, as the magnetic field increases, the magnetic The rheological fluid gradually transforms from liquid to semi-solid, and this process reacts rapidly and is reversible. Compared with the traditional magneto-rheological damper, the shear-mode magneto-rh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com