Special floating type static contact assembly device structure

A device structure and static contact technology, applied in the direction of circuit breaker contacts, circuit breaker components, etc., can solve the problems of inability to meet market demand, unfavorable actual mass production, complex design, etc., to improve the ability to make or break, The effect of protecting safety and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

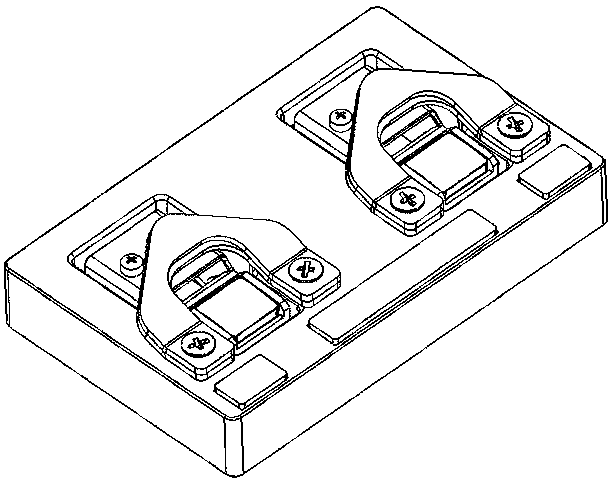

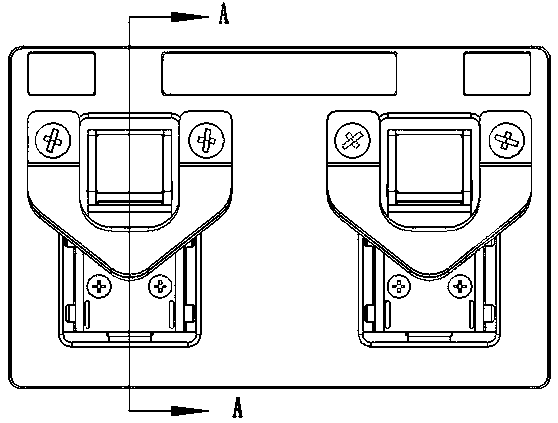

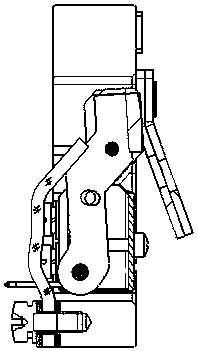

[0022] Such as Figure 1 to Figure 9 As shown, a special floating static contact assembly device structure described in the present invention includes a main static contact assembly 1, a clip-shaped piece 2, a floating arc-starting static contact assembly 3, and a clip-shaped piece fixing screw 4. Connecting screw 5, limit shaft 6, positioning shaft 7, torsion spring 8, limit screw 9 and arc striker 10, a groove cavity 101 is provided in the main static contact assembly 1, and the floating Arc strike static contact assembly 3 is composed of arc strike static contact 301, arc strike static contact silver alloy 302, arc shield 303, pin 304, copper braided wire 305 and pressure piece 306, and the arc shield 303 passes through the pin 304 is installed on the front end of the arc-starting static contact 301, the arc-starting static contact silver alloy 302 is arranged on the arc-blocking plate 303, and one end of the copper braided wire 305 is connected with the arc-starting static...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com