PCB (printed circuit board) splitting control system and PCB splitting control method

A technology of PCB board and control method, which is applied in the fields of printed circuit manufacturing, insulating substrate/layer processing, electrical components, etc., can solve the problems of low precision and low efficiency of board division, and achieve high production precision and high production efficiency , Reduce the use of human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Existing PCB splitting often adopts two methods, which are manual folding or splitting by a splitting machine; among them, the degree of automation of manual folding is low, and the PCB board is damaged due to manual operation errors; although the splitting machine is automated The degree is high, but there is still a certain error in the existing board splitting machine, and the precision is not high, resulting in a high product scrap rate.

[0038] In order to solve the above technical problems, this embodiment provides the following technical solutions:

[0039] This embodiment provides a PCB sub-board control system, including a material channel and a camera.

[0040] Specifically, the material processed in this embodiment is a material board, wherein the material board includes a material frame and a number of evenly arranged and connected PCB boards, and the PCB boards and the PCB board and the material frame are connected through nozzle materials.

[0041] Speci...

Embodiment 2

[0047] This embodiment will specifically describe how to perform precise board splitting through the PCB splitting control system provided in Embodiment 1.

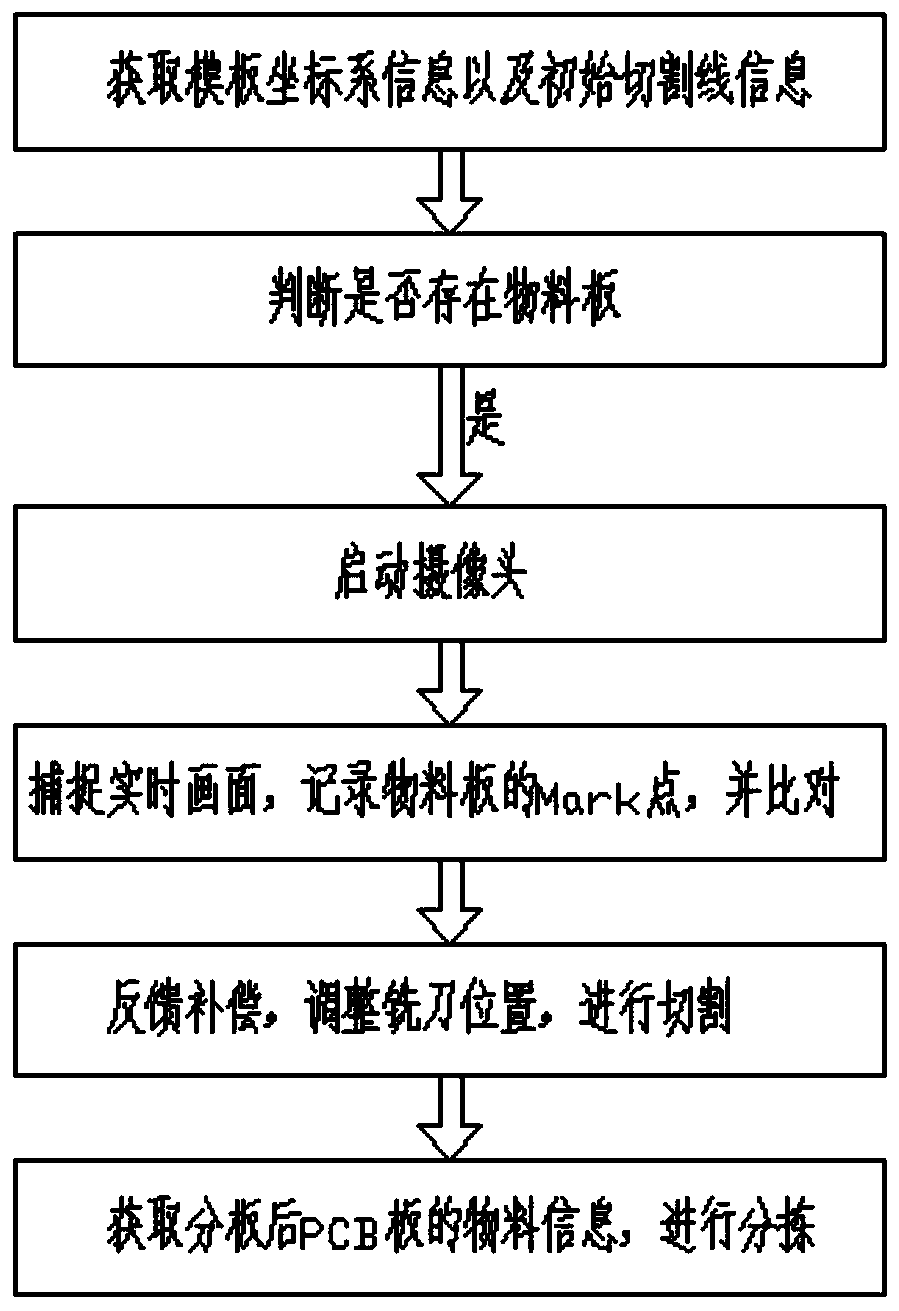

[0048] Specifically, this embodiment provides a control method for PCB sub-boards, including the following steps:

[0049] Step A100, obtaining the template coordinate system information of the material plate to be cut and the initial cutting line information corresponding to the template coordinate system information;

[0050] Step A200, detecting and judging whether there is a material plate in the material channel; if it exists, start the camera;

[0051] Step A300, the camera captures the real-time picture in the material channel, records the Mark point of the material plate and compares it with the template coordinate system information in step A100;

[0052] Step A400, perform feedback compensation according to the comparison result in step A300, obtain the cutting coordinate system information and the correspondin...

Embodiment 3

[0060] This embodiment will describe the specific way of acquiring template coordinate system information and initial cutting line information in step A100.

[0061] Specifically, the template coordinate system information and the initial cutting line information can be acquired through manual adjustment or directly retrieved from the database.

[0062] Further, the specific steps of manual adjustment acquisition are:

[0063] A101. Place the material plate to be cut in the material channel along the correct cutting direction;

[0064] A102. After the material channel transfers the material board to the cutting station, the camera captures the Mark point of the material board, and establishes a template coordinate system based on the Mark point;

[0065] A103. Manually adjust the milling cutter position and cutting direction, and record the initial cutting position and cutting direction with the template coordinate system as a standard.

[0066] In the actual production proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com