Boosting stirrer for biotechnology deep processing

A deep processing and agitator technology, which is applied in the field of biotechnology, can solve the problems of affecting the mixing effect and the inability to realize the mixing of upper and lower layers of raw materials, and achieve the effect of improving the mixing effect, simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

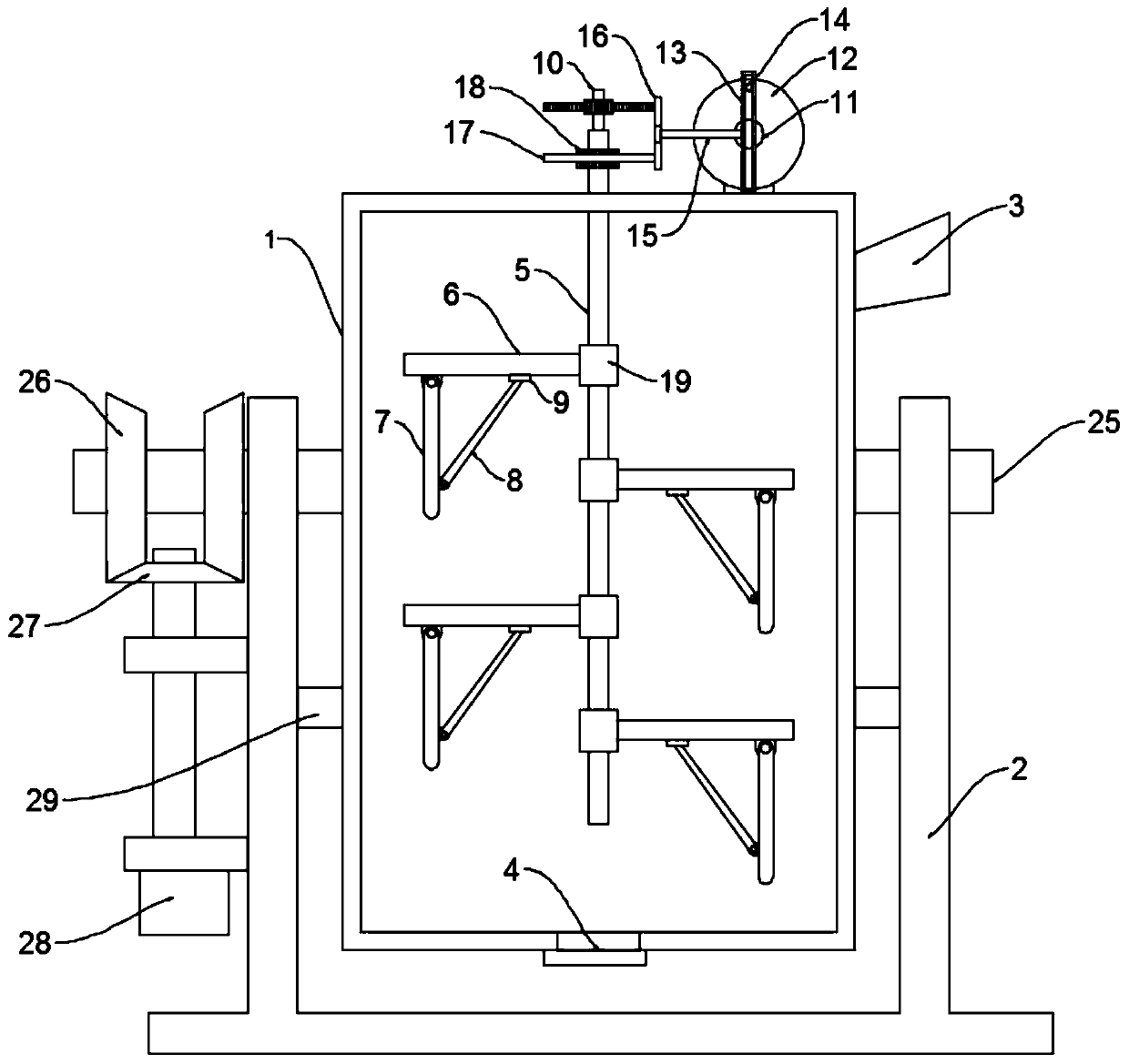

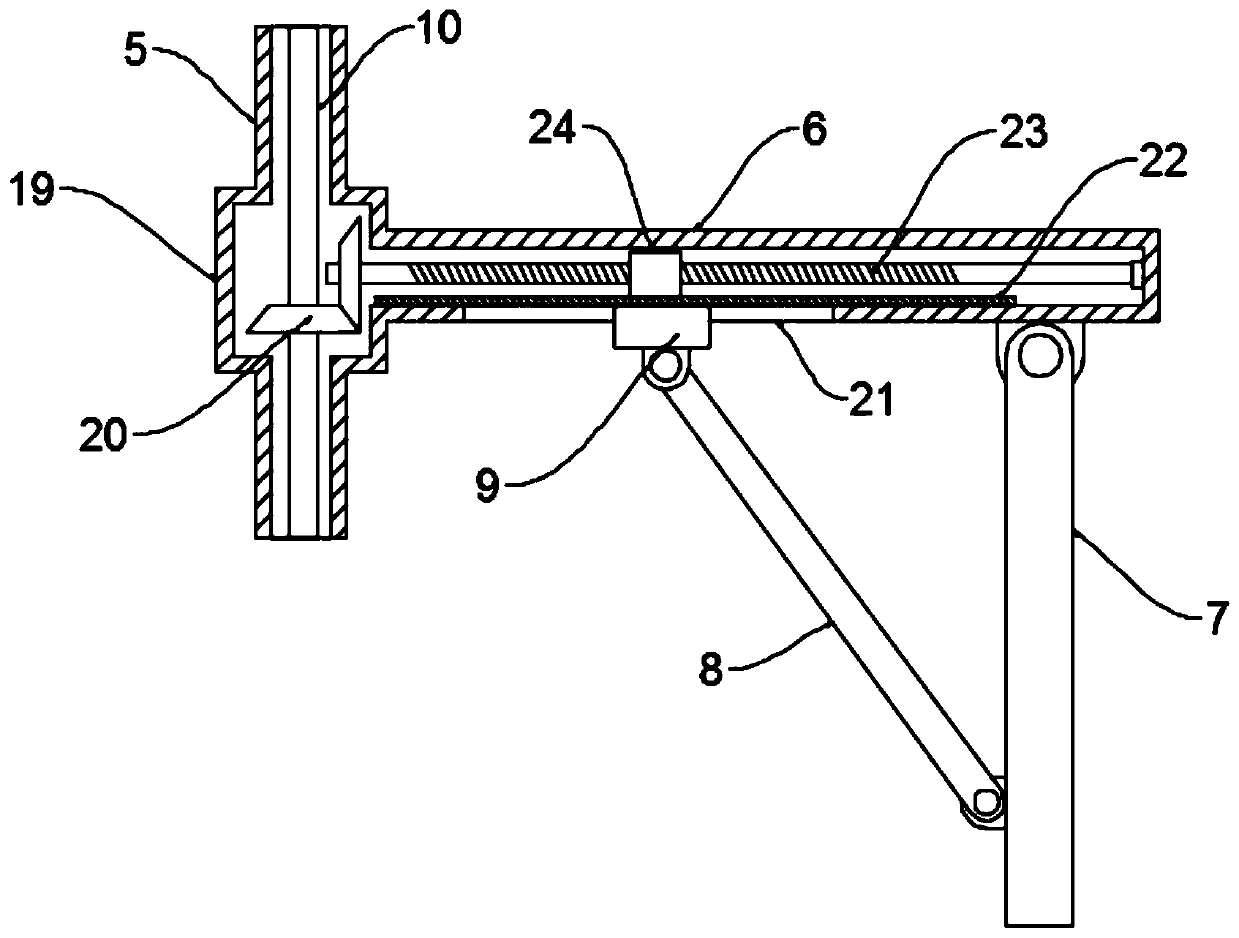

[0024] see figure 1 and 2 , in an embodiment of the present invention, a biotechnology deep processing booster agitator includes a stirring box 1, a feed hopper 3 is arranged on the side wall of the stirring box 1, and a rotating vertical rod is arranged inside the stirring box 1 The shaft 5 and the outer wall of the rotating vertical rod shaft 5 are equipped with a plurality of side stirring rods 6, and the end of each side stirring rod 6 away from the rotating vertical rod shaft 5 is hinged with a swing rod 7, and the ends of the side stirring rods 6 pass through the transmission shell The body 19 is fixedly connected with the rotating vertical rod shaft 5, and the inner rod shaft 10 which is rotatably connected with it is also arranged inside the rotating vertical rod shaft 5. The driving unit that rotates forward and backward with the inner rod shaft 10 and rotates the vertical rod shaft 5 and the inner rod shaft 10 keeps rotating in the opposite direction. The side stirr...

Embodiment 2

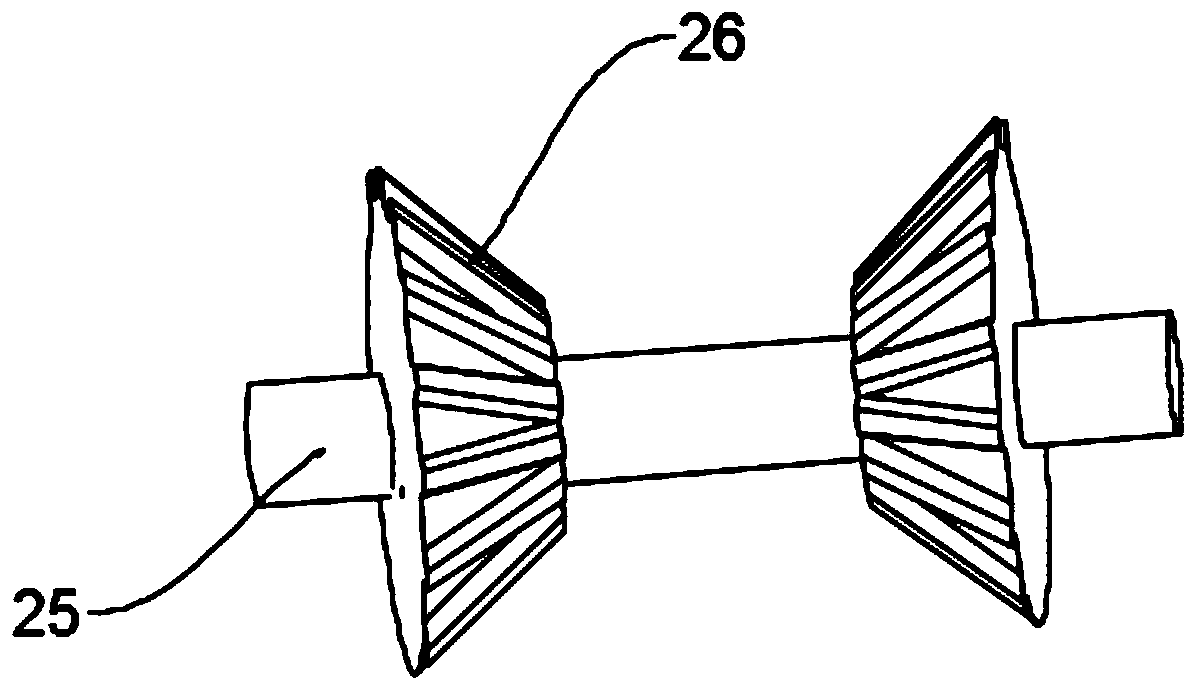

[0029] see Figure 1-4 The difference between this embodiment of the present invention and Embodiment 1 is that the installation rod shaft 25 is rotationally connected to the fixed bracket body 2 and the outer wall of the fixed bracket body 2 is provided with a power assembly that drives the installation rod shaft 25 to rotate positively and negatively. The above-mentioned power assembly includes a swing motor 28 arranged on the fixed bracket body 2 and two transmission bevel gears 26 arranged on the installation rod shaft 25, the two transmission bevel gears 26 are oppositely arranged and are incompletely arranged with the output end of the swing motor 28. The bevel gears 27 mesh alternately, and the swing motor 28 can be used to drive the incomplete bevel gears 27 to rotate and cooperate to make the installation rod shaft 25 rotate positively and negatively, thereby making the stirring box 1 swing to increase the vibration of the materials inside the stirring box 1 and improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com