Preheating welding device for steel structure installation construction

A welding device and steel structure technology, applied in welding equipment, gas flame welding equipment, manufacturing tools, etc., can solve the problems of no auxiliary tooling, heavy steel structure, high labor intensity, etc., to avoid harm, improve efficiency, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

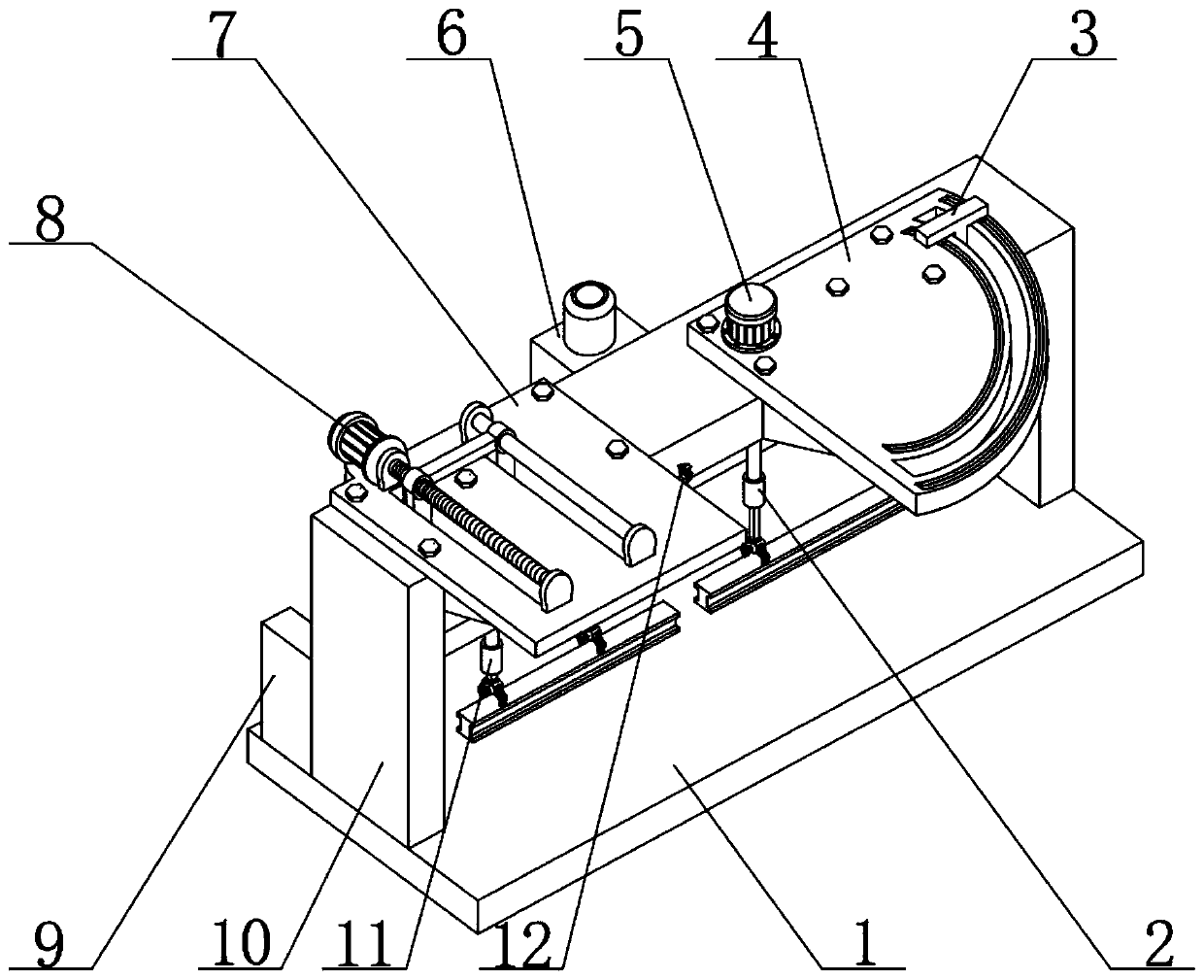

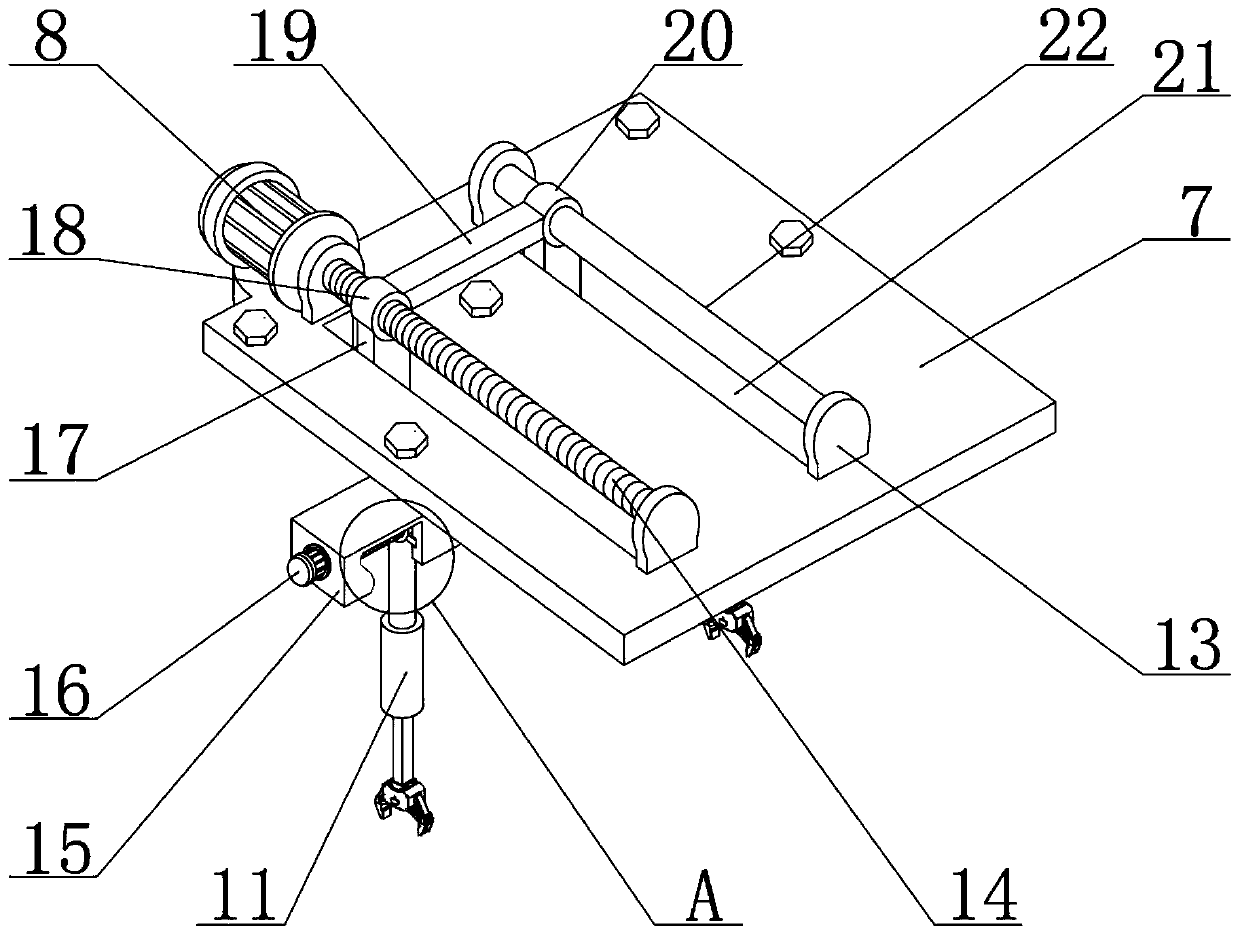

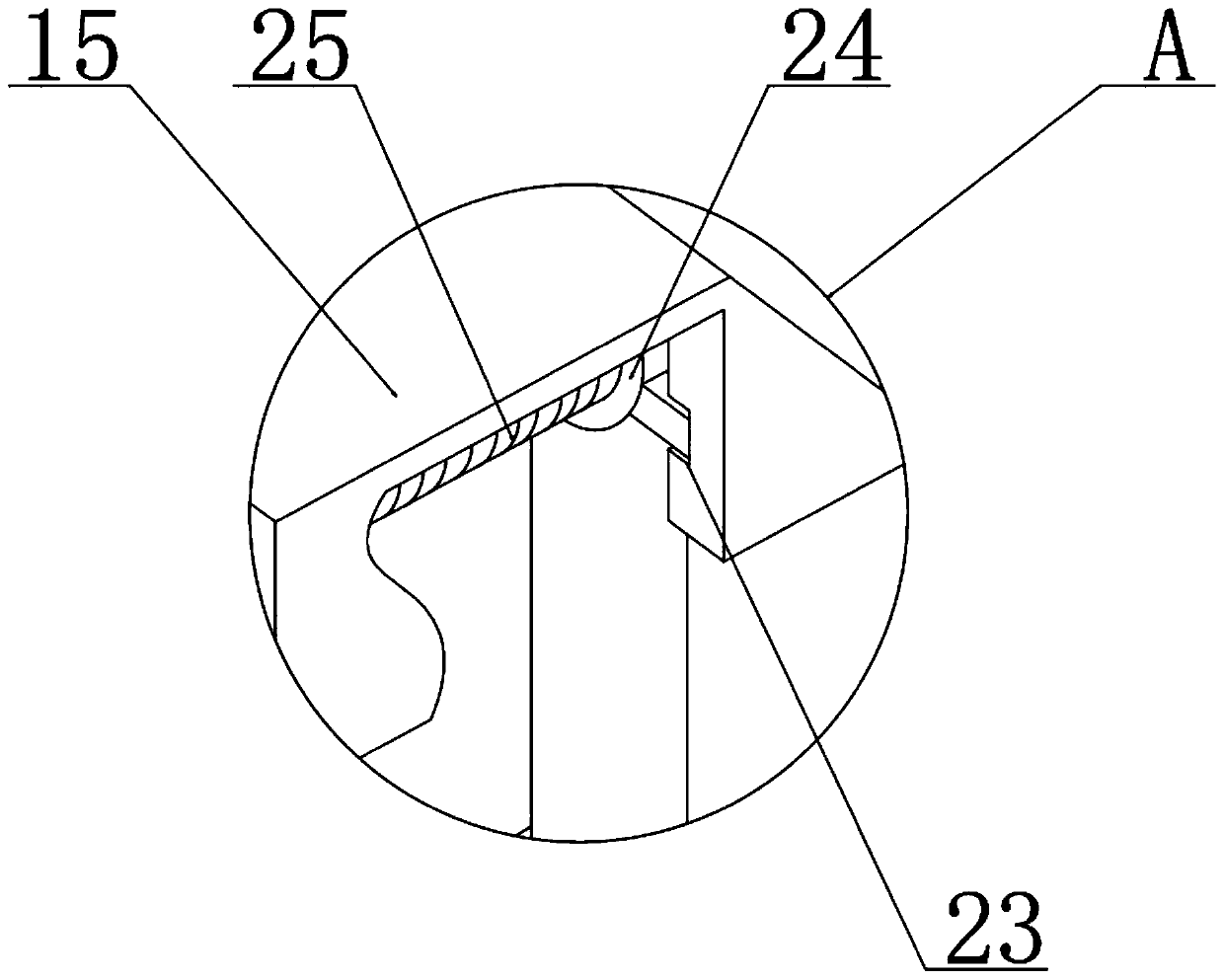

[0022] see Figure 1~6 , in an embodiment of the present invention, a preheating welding device for installation and construction of a steel structure includes a base 1, a gantry 10 is fixed above the base 1, and the top of the base 1 is located at one side of the gantry 10 Equipped with a PLC control cabinet 9, two second telescopic clamping assemblies 11 are arranged at the bottom of the gantry 10 at one end, and the position corresponding to the second telescopic clamping assembly 11 above the gantry 10 is fixed with a The vertical and horizontal adjustment mechanism, the vertical and horizontal adjustment mechanism includes a second support plate 7 fixed on the top of the gantry 10, a first screw 14 and a guide rod 22 are arranged in parallel above the second support plate 7, and the upper surface of the second support plate 7 The positions corresponding to the first screw mandrel 14 and the guide rod 22 are all provided with a limit chute 23 equal to its length, and a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com