Control method of pressure regulating pump of water purifier, and water purifier

A control method and water purifier technology, applied in water treatment parameter control, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as water pipe blasting, high pressure in front of the reverse osmosis membrane, noise, etc., to reduce noise and power consumption, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

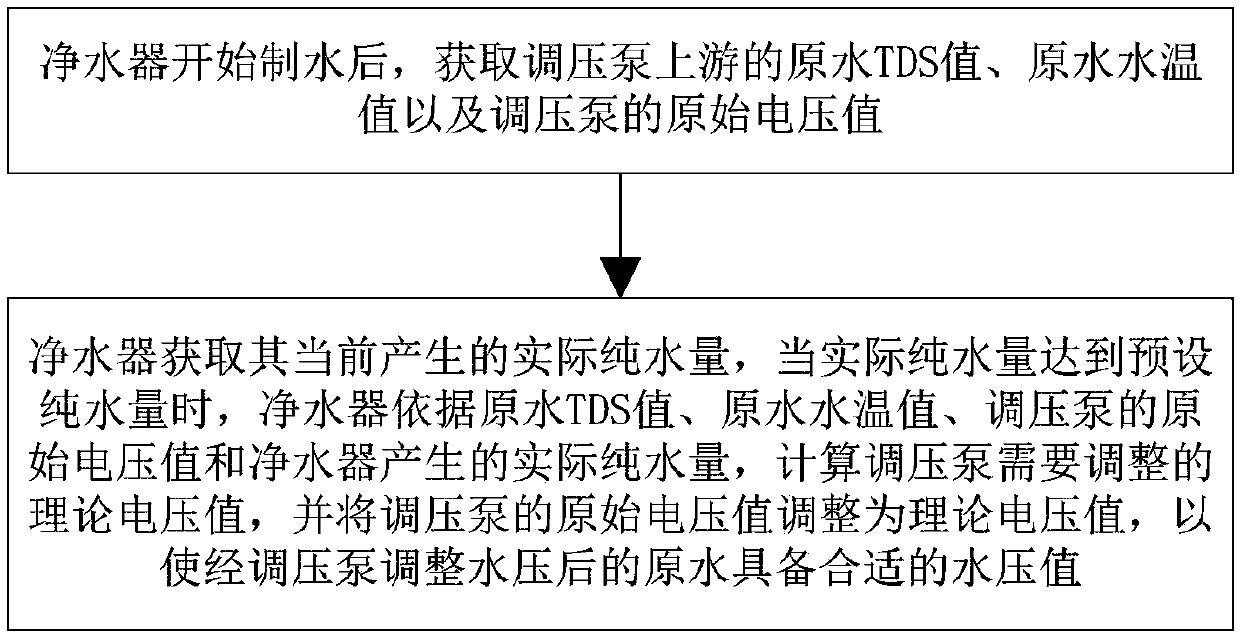

[0043] Such as figure 1 As shown, in this embodiment, a control method of the pressure regulating pump of the water purifier is provided, and the control method includes the following steps. Step 1: After the water purifier starts to produce water, obtain the raw water TDS value upstream of the pressure regulating pump 8 , the raw water temperature value and the original voltage value of the regulator pump 8; step 2: the water purifier obtains the actual pure water volume it currently produces, and when the actual pure water volume reaches the preset pure water volume, the water purifier uses the TDS value of the raw water , the raw water temperature value, the original voltage value of the pressure regulating pump 8 and the actual pure water volume produced by the water purifier, calculate the theoretical voltage value that needs to be adjusted by the pressure regulating pump 8, and adjust the original voltage value of the pressure regulating pump 8 to the theoretical voltage ...

Embodiment 2

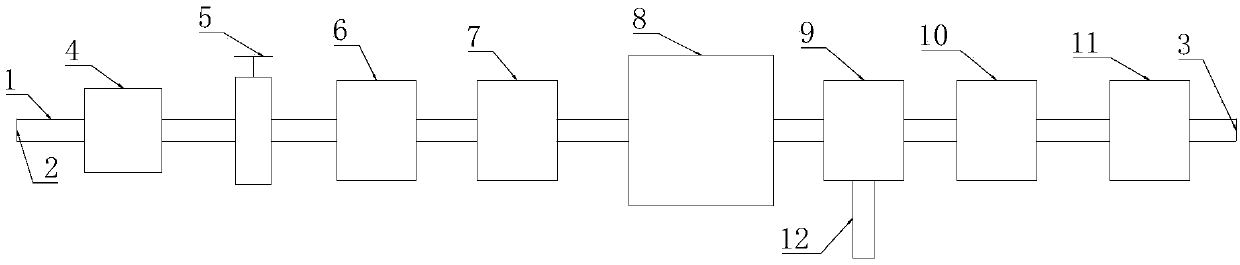

[0056] Such as figure 2 As shown, in this embodiment, the water purifier includes a water purification pipe 1, and the two ends of the water pipe are respectively a water inlet 2 and a water outlet 3, and the water purification pipe 1 is sequentially provided with a first filter unit along the direction of water flow. 4. Water inlet solenoid valve 5, temperature detection unit 6, TDS detection unit 7, pressure regulating pump 8, reverse osmosis membrane unit 9, flow detection unit 10 and second filter unit 11. A concentrated water pipe 12 is connected to the reverse osmosis membrane unit 9 , and the concentrated water produced after being treated by the reverse osmosis membrane unit 9 flows out through the concentrated water pipe 12 . The water treated by the reverse osmosis membrane unit 9 is discharged through the water outlet 3 after being treated by the second filter unit 11 to form pure water for human use; a control unit is arranged inside the water purifier, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com