Heat dissipation system of integrated circuit tester and control method thereof

An integrated circuit and heat dissipation system technology, which is applied in the field of integrated circuit tester heat dissipation system, can solve the problems of large power loss and noise pollution, and achieve the effects of reducing power consumption and noise, solving large power loss, and solving serious noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

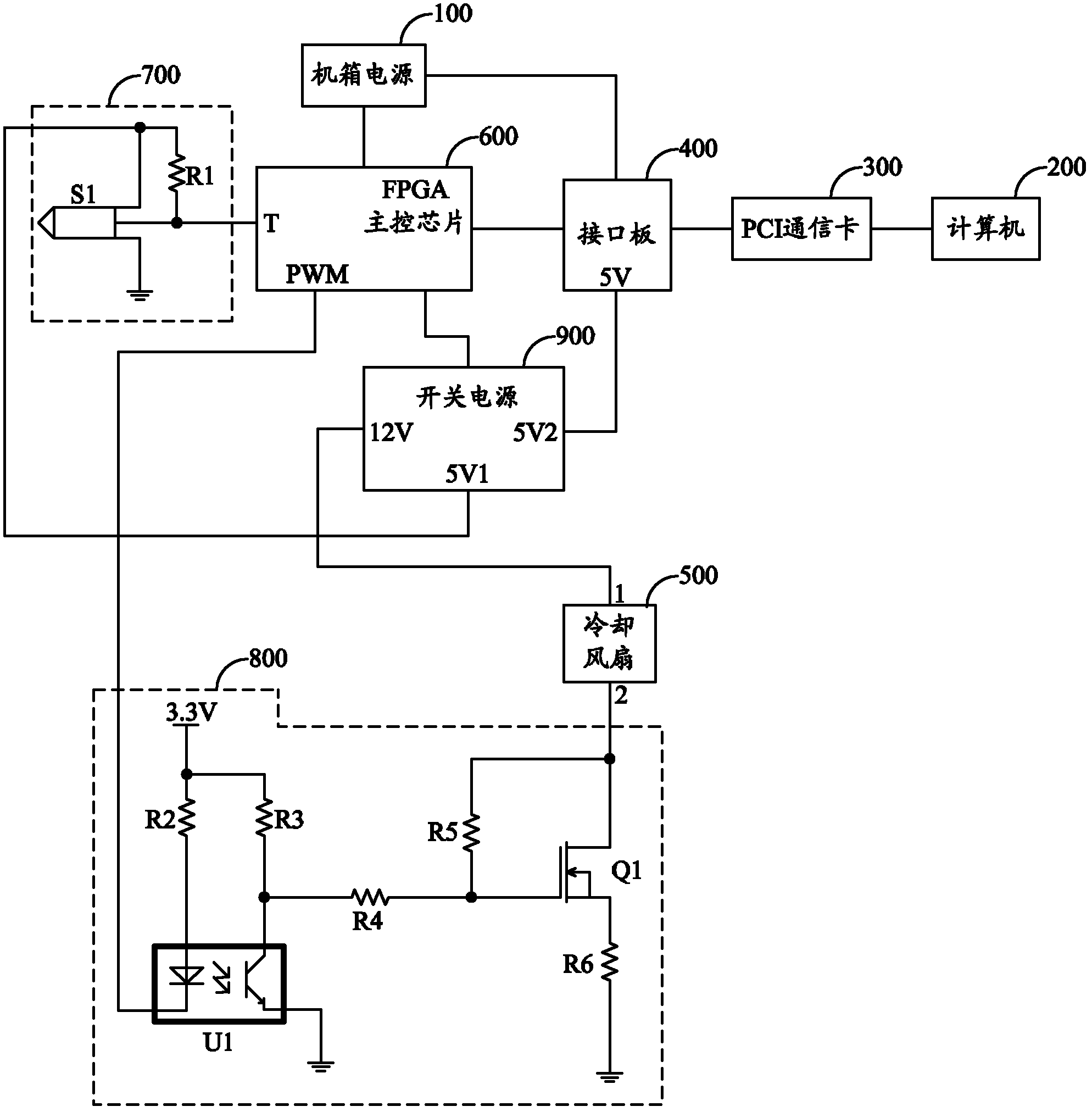

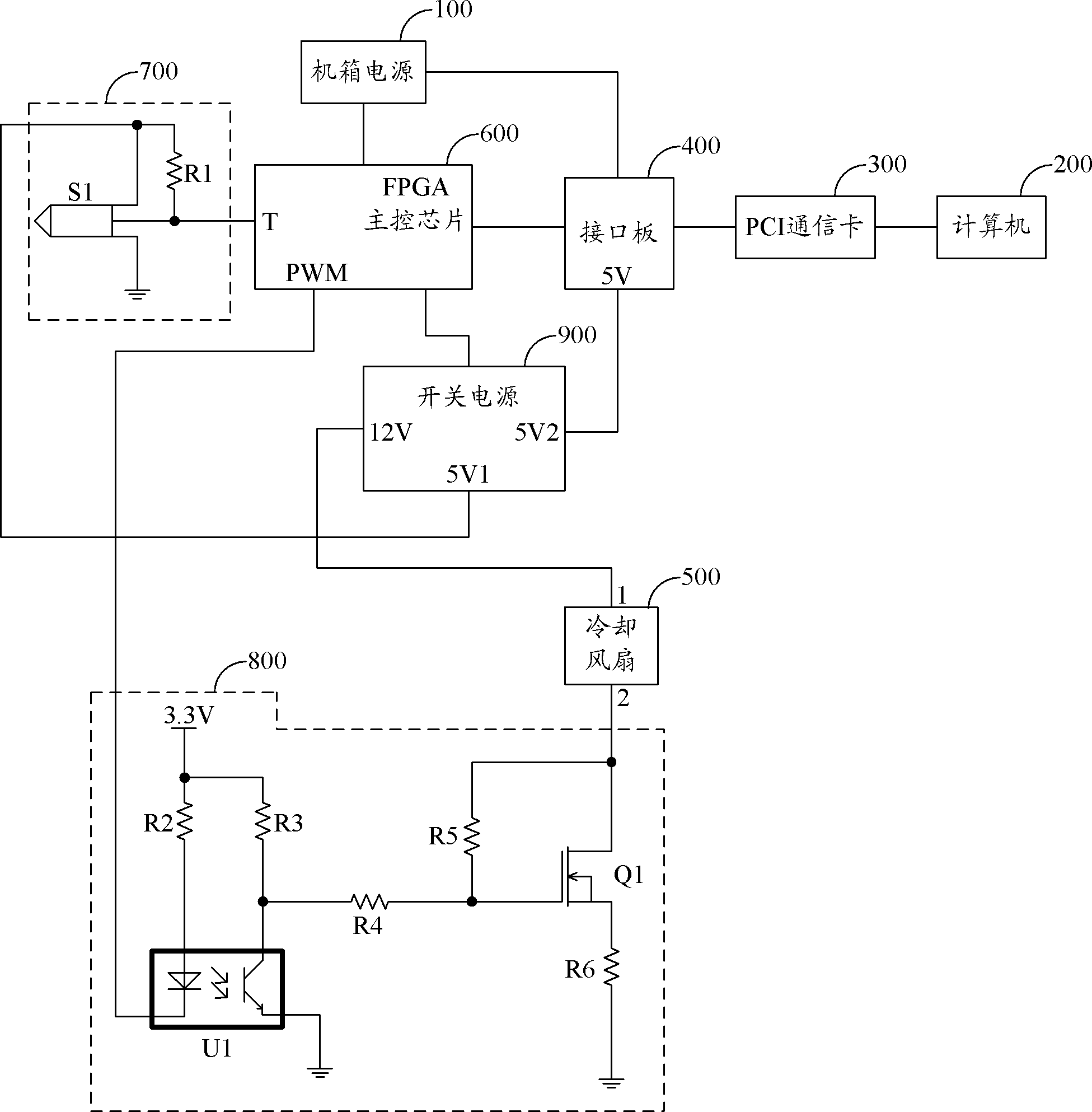

[0024] figure 1 An example circuit structure of the heat dissipation system of the integrated circuit tester provided by the first embodiment of the present invention is shown. For the convenience of description, only the parts related to the first embodiment of the present invention are shown, and the details are as follows:

[0025] A heat dissipation system for an integrated circuit tester, connected to a chassis power supply 100 of the integrated circuit tester, including a computer 200, a PCI communication card 300, an interface board 400 and a cooling fan 500, the integrated circuit tester heat dissipation system also includes:

[0026] The FPGA main control chip 600 is connected with the chassis power supply 100 and the interface board 400, and is used to control the peripheral equipment units accordingly according to the control instructions of the computer 200;

[0027] The temperature sensing unit 700 is arranged outside the chassis of the integrated circuit tester a...

Embodiment 2

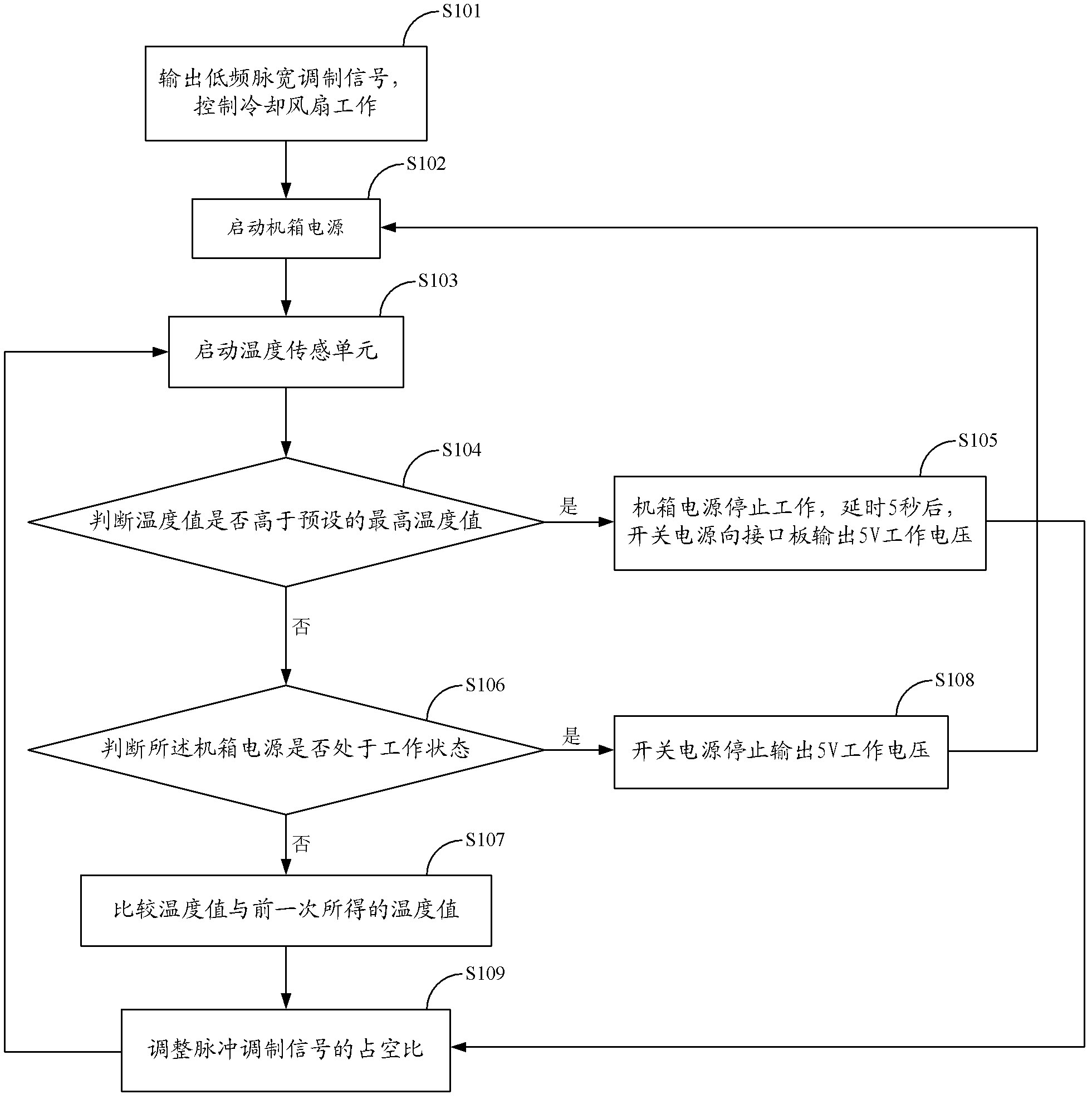

[0038] In the embodiment of the present invention, the cooling system of the integrated circuit tester in the first embodiment is used to monitor the chassis temperature of the integrated circuit tester, and output a low-frequency pulse width modulation signal to adjust the speed of the cooling fan according to the change of the chassis temperature, thereby To achieve the purpose of reducing power consumption and noise.

[0039] figure 2 It shows the implementation process of the heat dissipation control method of the integrated circuit tester provided by the second embodiment of the present invention. For the convenience of description, only the parts related to the second embodiment of the present invention are shown, and the details are as follows:

[0040] The method for controlling the cooling system of an integrated circuit tester includes the following steps:

[0041] Step 101, outputting a low-frequency pulse width modulation signal to control the cooling fan to work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com