A sewage treatment process and device for instant food processing and extraction

A sewage treatment device and food processing technology, which is applied in the direction of food industry wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as environmental pollution, condensed water can not be recycled, increase investment costs, etc., to achieve Avoiding discharge and polluting the environment, good practical value, and the effect of saving mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

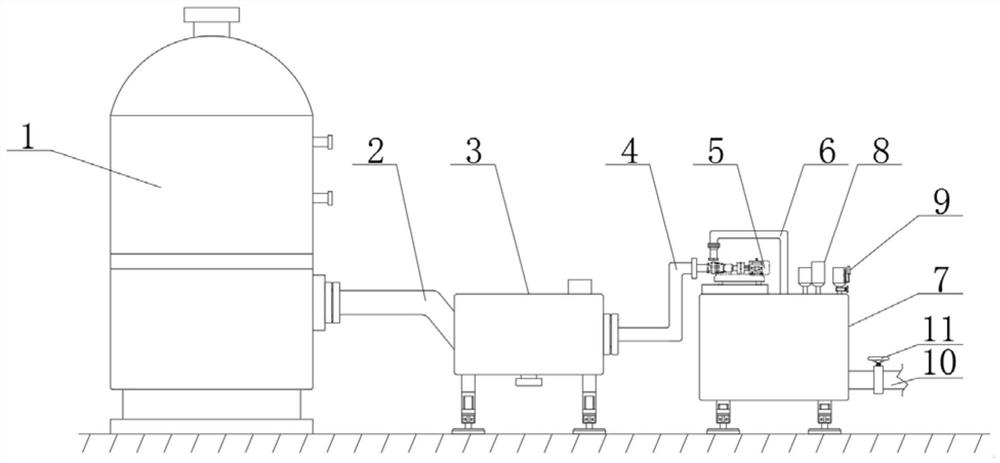

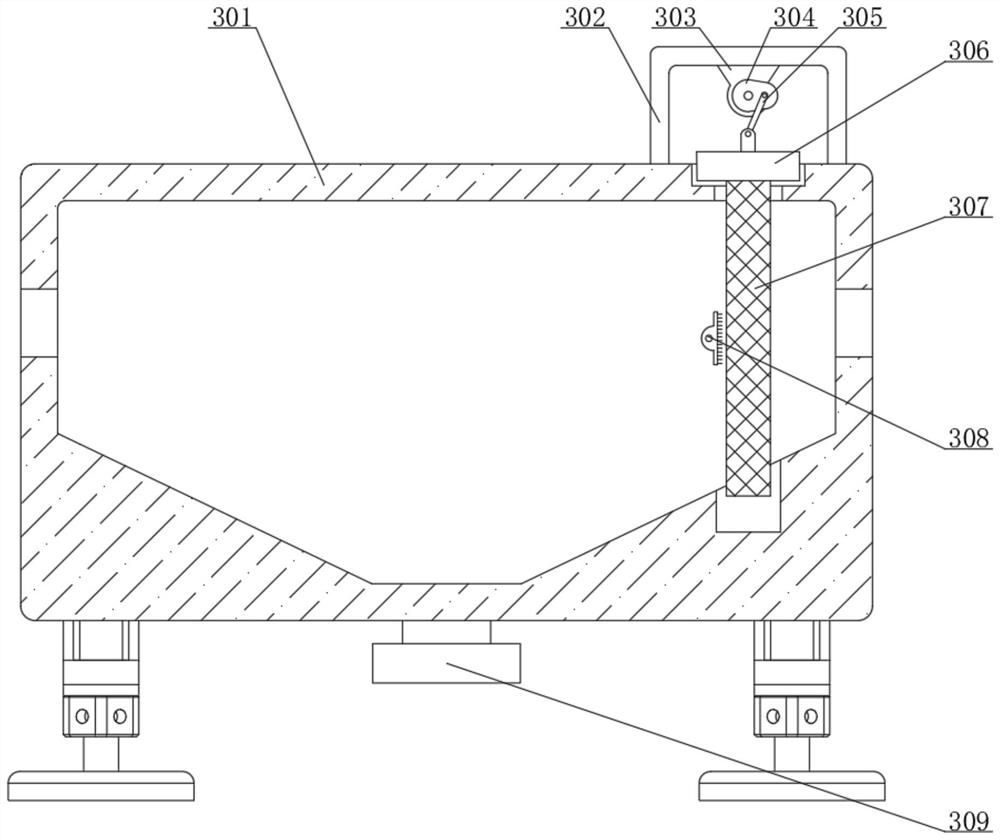

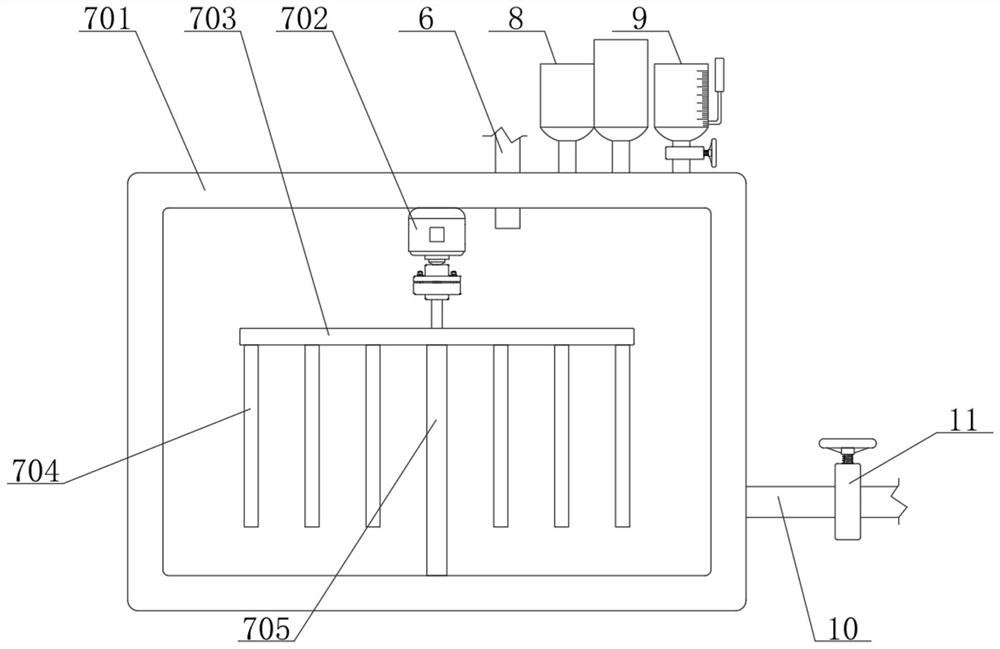

[0029] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution:

[0030]A sewage treatment device for instant food processing and extraction, comprising a tank body 1 and a delivery pipe 2, the right end of the tank body 1 is fixedly connected with the delivery pipe 2, and the right end surface of the delivery pipe 2 is fixedly connected with a filter device 3, and the filter device 3 includes a filter box 301 and protective frame 302, the upper end of filter box 301 is fixedly connected with protective frame 302, the inside of protective frame 302 is fixedly connected with rotating motor 303, and the end of rotating motor 303 main shaft is fixedly connected with eccentric wheel 304, this setting can make filter screen 307 up and down To ensure that impurities are not easy to accumulate on the surface of the filter screen 307, the outer side of the eccentric wheel 304 is rotatably connected with a connecting rod 3...

Embodiment 2

[0038] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution:

[0039] A sewage treatment device for instant food processing and extraction, comprising a tank body 1 and a delivery pipe 2, the right end of the tank body 1 is fixedly connected with the delivery pipe 2, and the right end surface of the delivery pipe 2 is fixedly connected with a filter device 3, and the filter device 3 includes a filter box 301 and protective frame 302, the upper end of filter box 301 is fixedly connected with protective frame 302, the inside of protective frame 302 is fixedly connected with rotating motor 303, and the end of rotating motor 303 main shaft is fixedly connected with eccentric wheel 304, this setting can make filter screen 307 up and down To ensure that impurities are not easy to accumulate on the surface of the filter screen 307, the outer side of the eccentric wheel 304 is rotatably connected with a connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com