Chemical strengthening method for improving falling resistance and surface hardness of glass

A surface hardness and chemical technology, used in the field of improving glass drop resistance and surface hardness, to achieve the effect of high surface hardness, strong drop resistance, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is a chemical strengthening method for improving the drop resistance and surface hardness of glass. The specific operation is divided into three steps, which are the glass plate pretreatment process, the first chemical strengthening process and the second chemical strengthening process.

[0013] In the glass plate pretreatment process, the glass needs to be placed in a mixed solution of sulfuric acid and sodium sulfate at a temperature of 50-60°C for 1-2 hours. The original sharp cracks on the glass surface are rounded due to the corrosion of hydrogen ions. When treated with a mixed solution, the hydrogen ions in the solution exchange with the lithium ions and sodium ions in the glass, forming a surface layer rich in hydrogen ions on the glass surface, which promotes ion exchange for subsequent chemical strengthening.

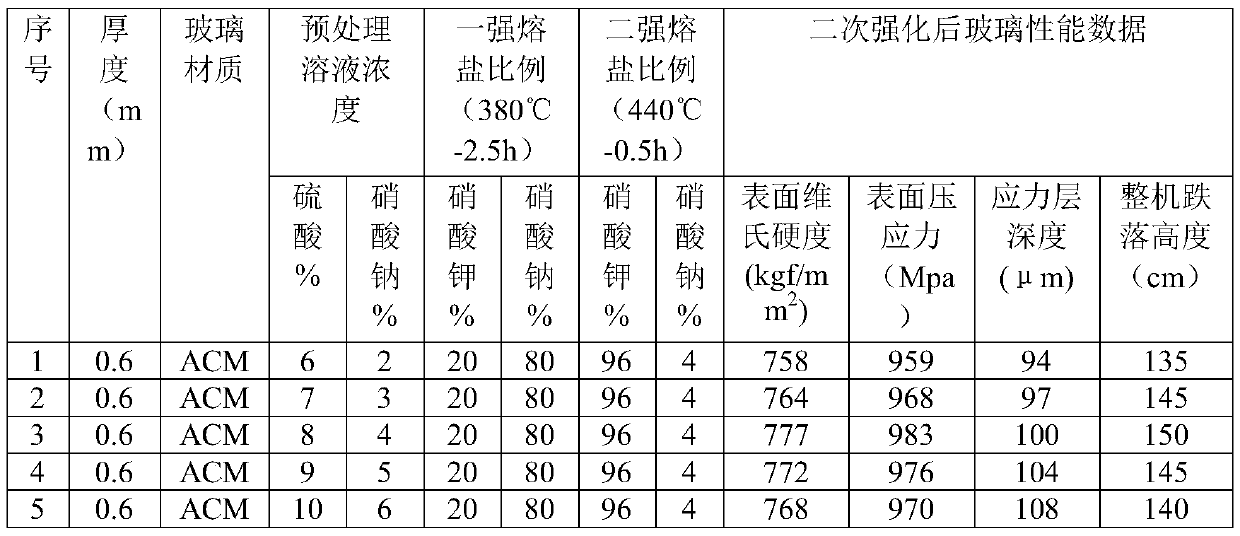

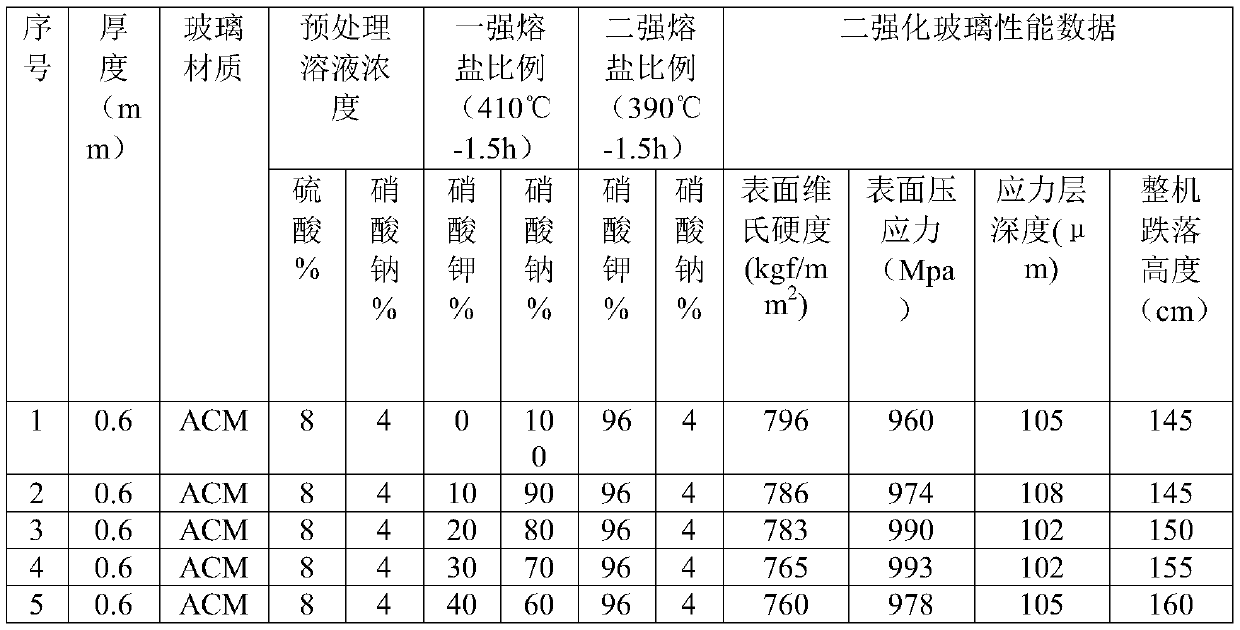

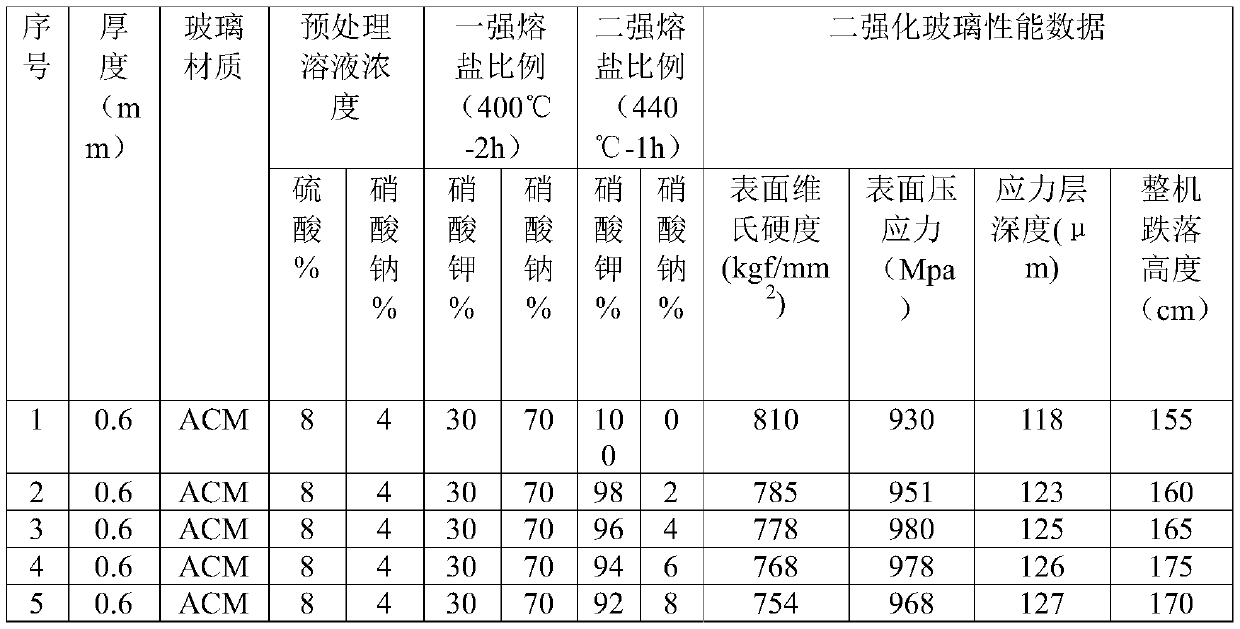

[0014] In the glass plate pretreatment process, it is necessary to use a mixed solution with a ratio (mass fraction) of 6%-10% sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com