A kind of production method of dq process thin gauge wear-resistant steel

A production method and thin-gauge technology, applied in the field of wear-resistant steel, can solve the problems of no innovation in chemical composition and smelting, and no solution to key technologies, so as to achieve excellent toughness and formability, controllable roll shape, and low yield ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

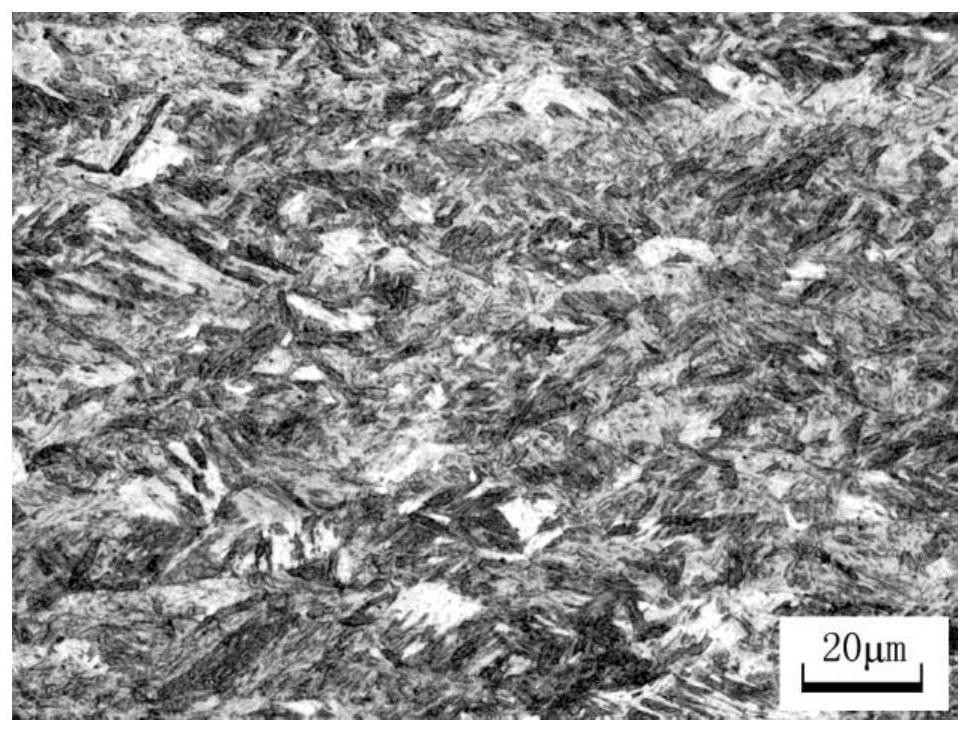

[0034] Such as figure 1 As shown, the production method of the DQ process thin-gauge wear-resistant steel of the embodiment of the present invention: the selected chemical composition is: 0.13%C, 1.50%Mn, 0.50%Si, P≤0.010%, S<0.005%, 0.5% %Cr, 0.2%Ti, 0.005%B, the balance is Fe, and the following processes: smelting, rough rolling, finishing rolling, DQ, coiling, Kaiping and delivery are carried out in sequence;

[0035] Heat the cast slab with a thickness of 230mm to 1220°C for 4 hours to fully austenitize it, then roll it at 1080°C to form a slab with a thickness specification of 85mm, start finish rolling at 1000°C, and finish rolling at 840°C to form a steel plate with a thickness specification of 10mm , the steel plate passing speed is 1.8m / s, after finishing rolling, the first 3m of the steel plate is air-cooled, and immediately cooled in single-phase cooling mode (spline mode), the cooling water ratio is 65 / 85, the cooling rate is 40°C / s, and then enters the densificati...

Embodiment 2

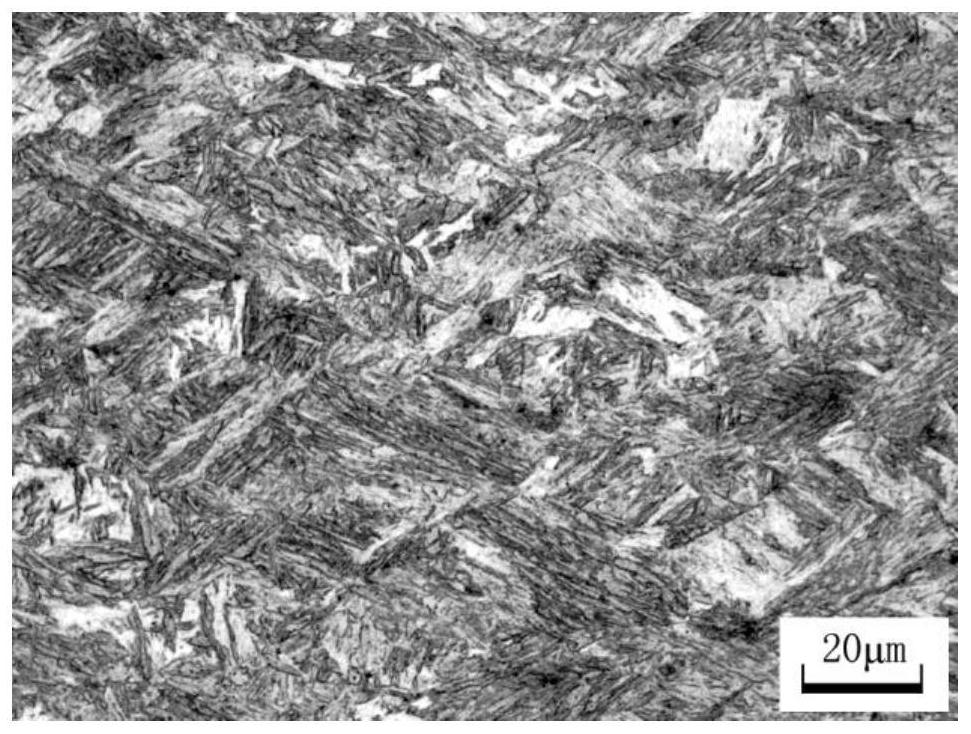

[0037] Such as figure 2 As shown, the production method of the DQ process thin-gauge wear-resistant steel of the embodiment of the present invention: the selected chemical composition is: 0.16%C, 1.0%Mn, 0.20%Si, P≤0.010%, S<0.005%, 0.2% %Cr, 0.10%Ti, 0.002%B, the balance is Fe, and the following processes: smelting, rough rolling, finishing rolling, DQ, coiling, Kaiping and delivery are carried out in sequence;

[0038]Heat the cast slab with a thickness of 230mm to 1280°C for 2 hours to fully austenitize it, then roll it at 1080°C to form a slab with a thickness specification of 95mm, start finish rolling at 1020°C, and finish rolling at 880°C to form a steel plate with a thickness specification of 4mm , the steel plate passing speed is 4.5m / s, after the finishing rolling, the first 3m of the steel plate is air-cooled, immediately cooled in spline mode, the cooling water ratio is 60 / 80, the cooling rate is 80°C / s, and then enters the densification section to cool for 3s, at...

Embodiment 3

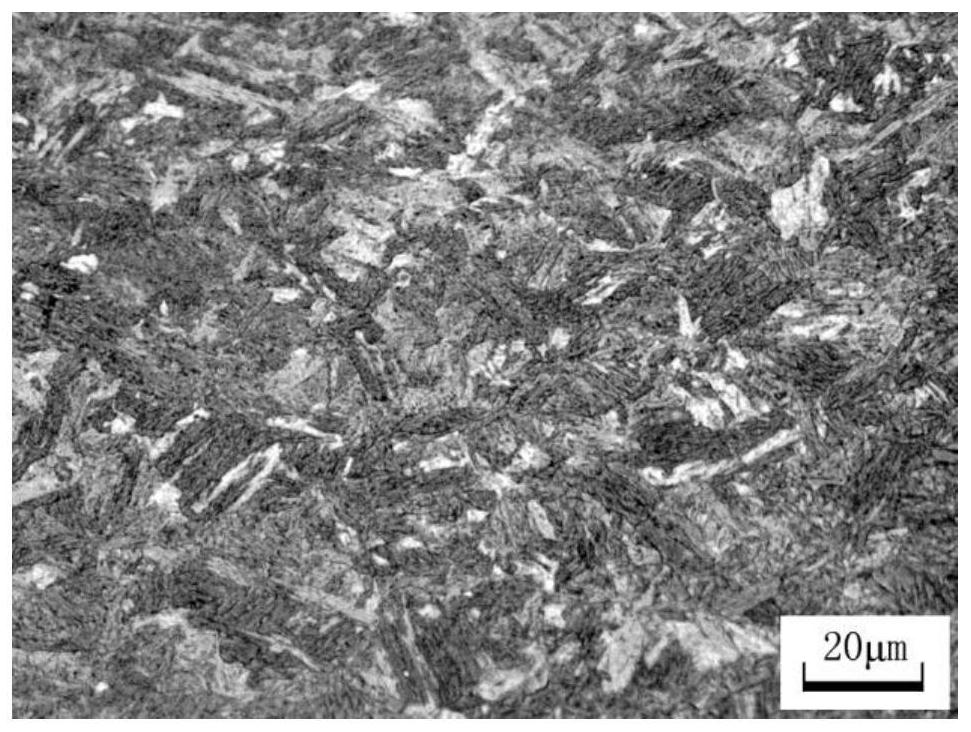

[0040] Such as image 3 As shown, the production method of the DQ process thin-gauge wear-resistant steel of the embodiment of the present invention: the selected chemical composition is: 0.15%C, 1.2%Mn, 0.40%Si, P≤0.010%, S<0.005%, 0.4% %Cr, 0.15%Ti, 0.002%B, the balance is Fe, and the following processes: smelting, rough rolling, finishing rolling, DQ, coiling, Kaiping and delivery are carried out in sequence;

[0041] Heat the cast slab with a thickness of 230mm to 1250°C for 3 hours to fully austenitize it, then roll it at 1050°C to form a slab with a thickness specification of 90mm, start finish rolling at 1000°C, and finish rolling at 860°C to form a steel plate with a thickness specification of 12mm , the steel plate passing speed is 3.5m / s, after the finish rolling, the first 3m of the steel plate is air-cooled and the first 3m of the steel plate passes, then it is cooled in spline mode, the cooling water ratio is 70 / 85, and the cooling rate is 70°C / s, and then it ente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com