Corrosion-inhibiting steel for aluminum-clad substrate and manufacturing method thereof

A technology for corrosion inhibition and manufacturing methods, applied in the field of steel for aluminum-clad substrates and its manufacturing, can solve problems affecting the use of aluminum-clad strip steel, corrosion of steel-aluminum cross-sections, and lack of steel-aluminum bonding properties, etc., to achieve low cost and high efficiency. The effect of production efficiency and excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

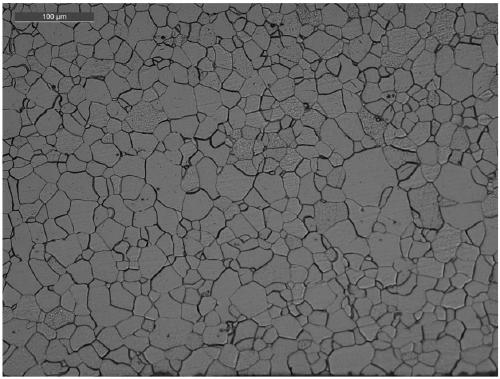

Image

Examples

Embodiment 1-8

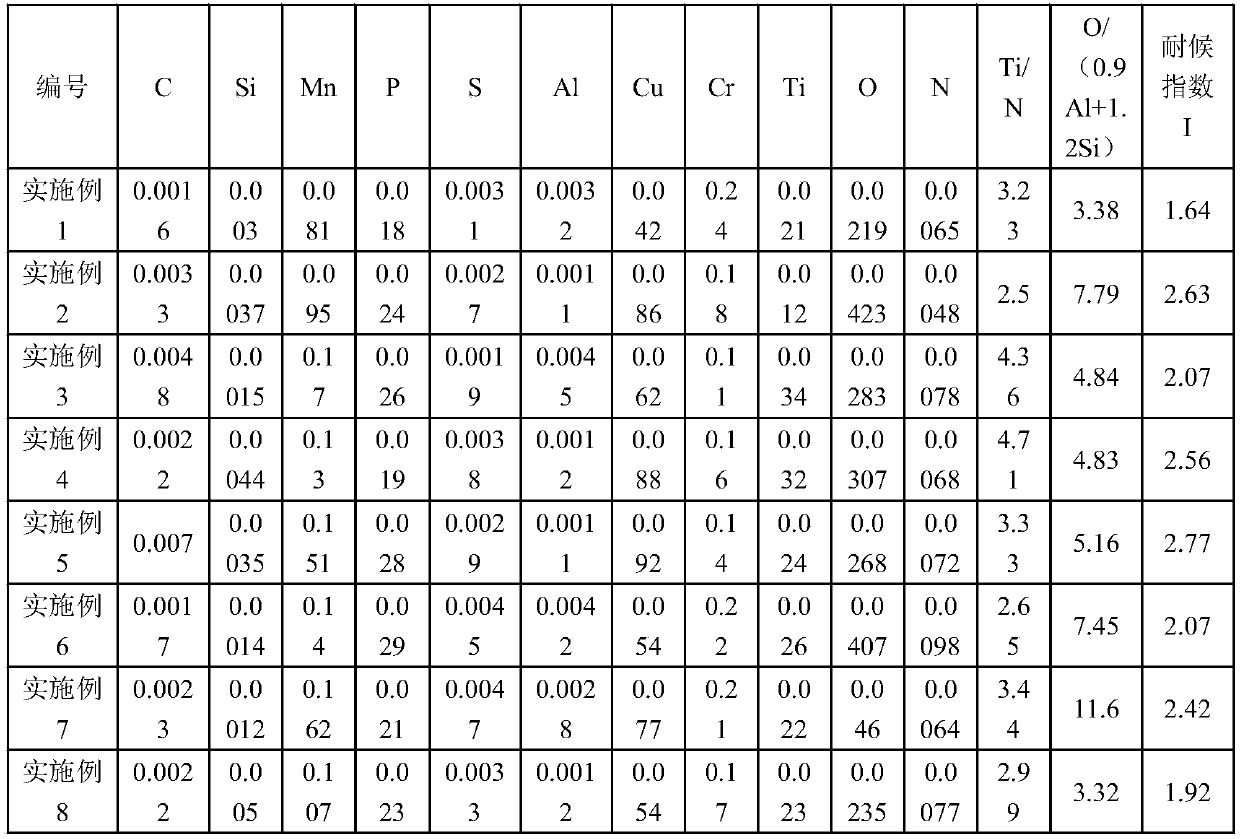

[0056] Table 1 lists the mass percentage (wt%) of each chemical element in the steel for corrosion-inhibiting aluminum-clad substrates of Examples 1-8.

[0057] Table 1. (wt%, the balance is Fe and other unavoidable impurity elements except S)

[0058]

[0059] It can be seen from Table 1 that compared with the prior art, the mass percentages of Si and Al in each embodiment of this case are below 0.005%, the mass percentage of O is between 0.02-0.05%, and the mass percentage of N is between 0.0040- 0.010%. In addition, in this case, P is added as a favorable element, therefore, the mass percentage of P is controlled at 0.018-0.03%.

[0060] The manufacturing method of the corrosion-inhibiting aluminum-clad substrate steel of embodiment 1-8 adopts the following steps to obtain:

[0061] (1) Smelting and casting: According to the chemical element composition shown in Table 1, smelt on a 500kg vacuum induction furnace, and cast to obtain a slab.

[0062] (2) Reheating: the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com