Method for detecting impurity elements and content thereof in graphene oxide

A detection method and impurity element technology, which is applied in the detection field of impurity elements and their content in graphene oxide, can solve the problems of large detection error and unstable base peak, and achieve the effect of simple operation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] S10: Use a small medicine spoon to take a small amount of high-purity aluminum powder and fill it into a high-purity tantalum block. After compacting with a manual powder briquette, it can be put into a glow discharge mass spectrometer for detection. Parallel detection is performed 5 times and the detection data is saved. And calculate the average value of the detection results.

[0071] S20: Weigh 0.03-0.5g graphene oxide, and record the mass M of the sample GO , put the sample in a vacuum drying oven for pretreatment for 4-12h, after the pretreatment is completed, take it out, weigh it, and record the mass M of the sample after the pretreatment is completed G , and then put it into a 10-25cm agate crucible, and grind it for 10min-30min. Then weigh 0.3-10g high-purity aluminum powder and put it into an agate crucible, and record the quality M of high-purity aluminum powder taken by weighing Al , and then grind for 30-60min, after the two are evenly mixed, the sample ...

Embodiment 2

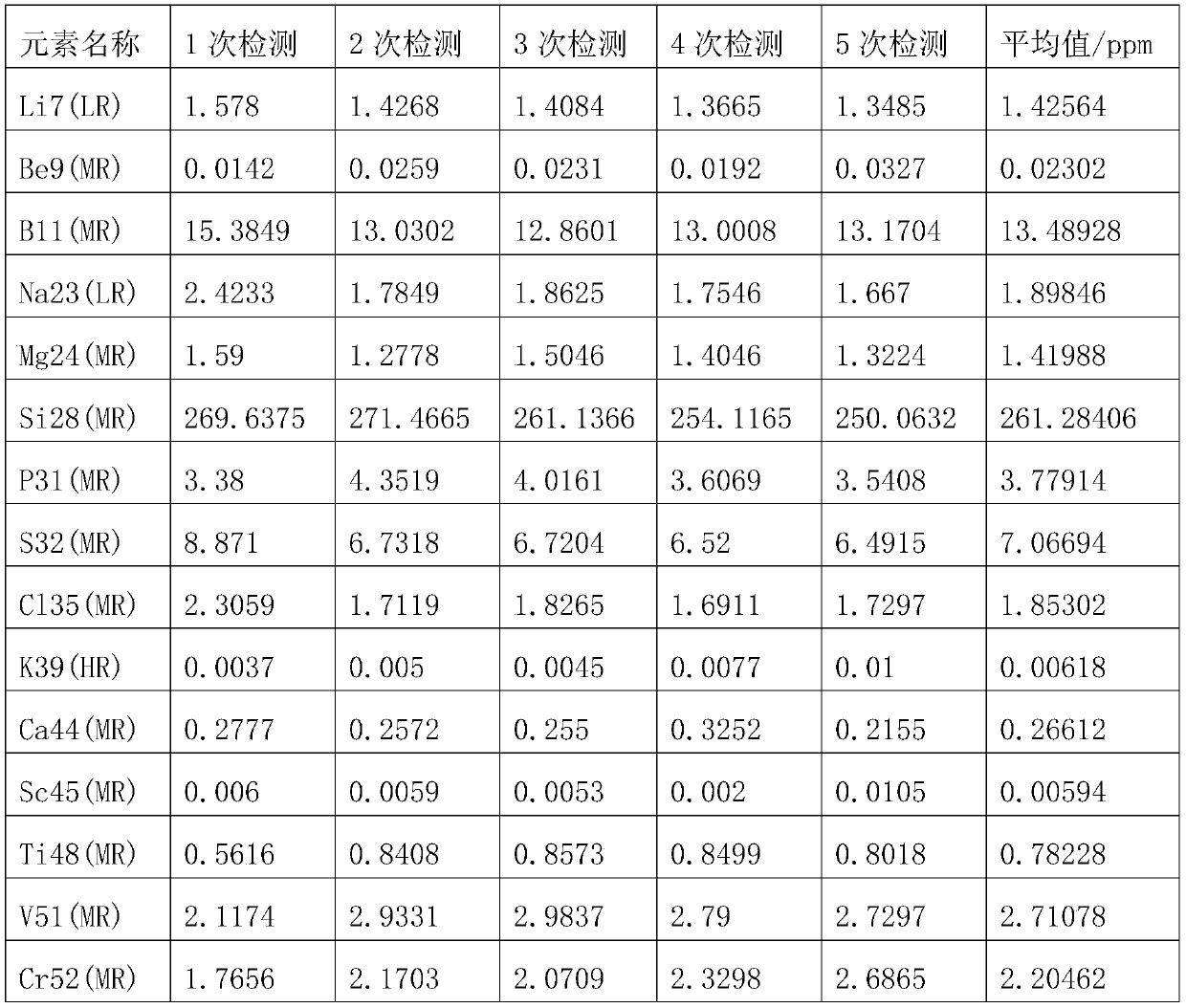

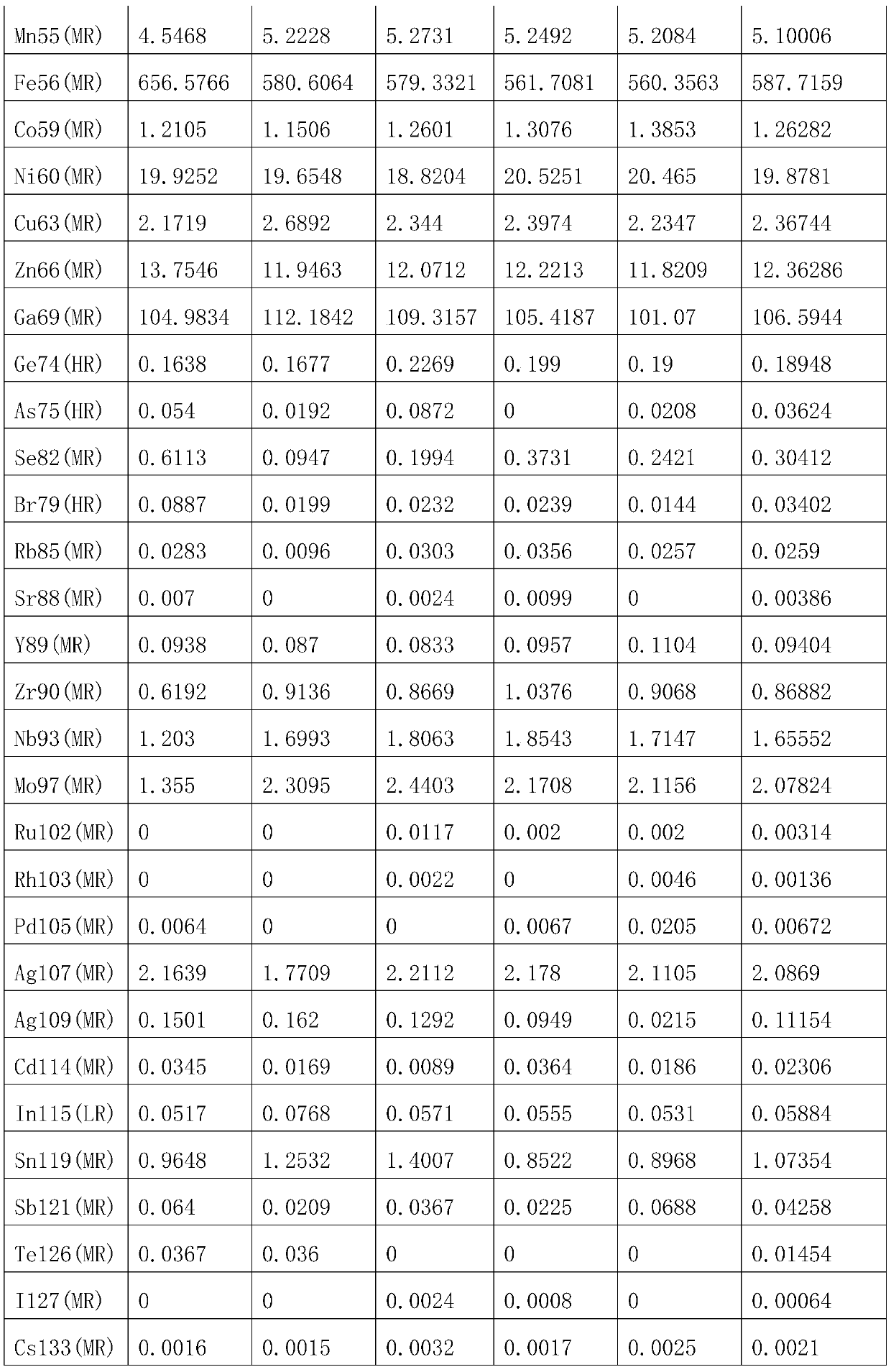

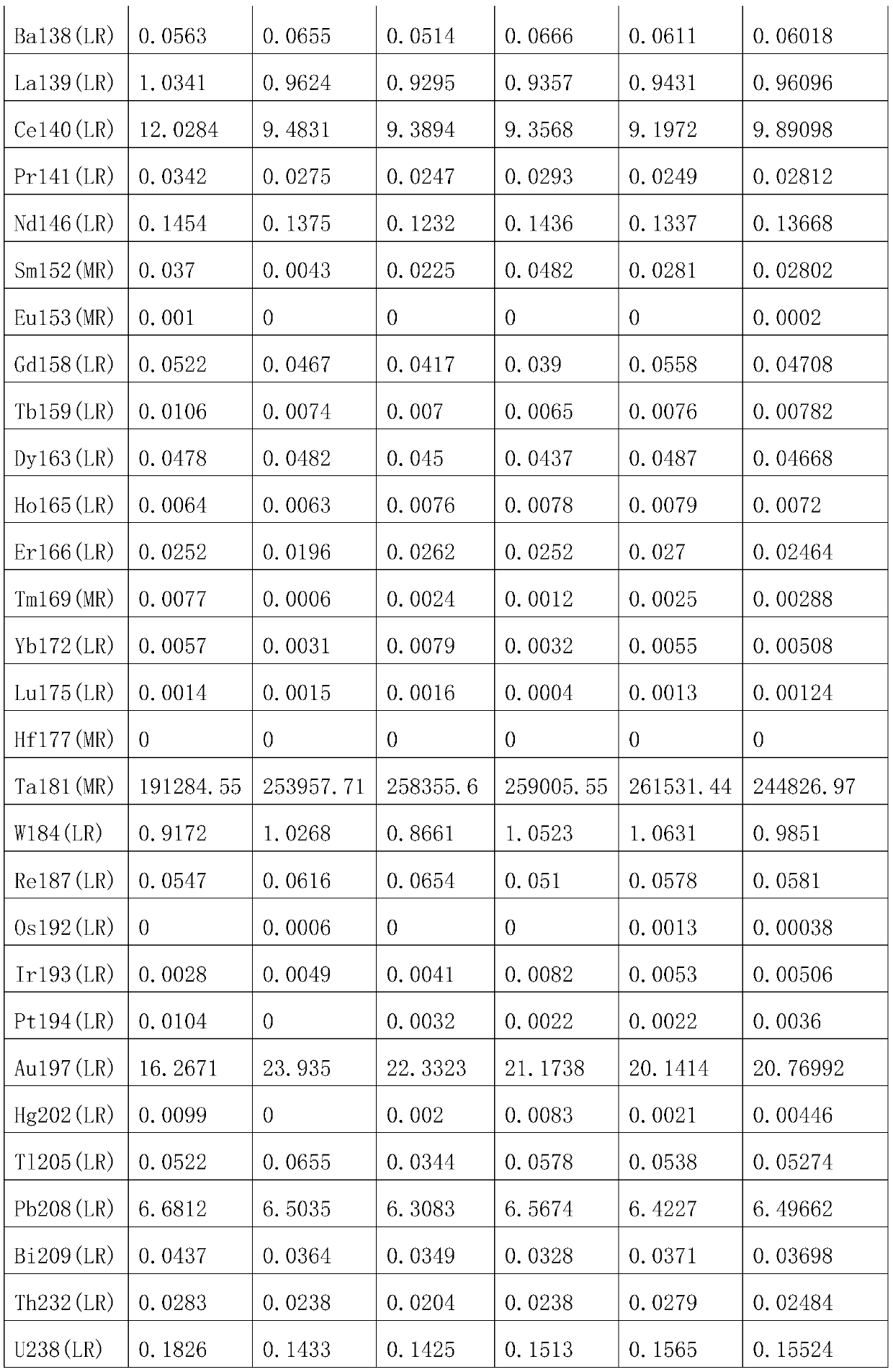

[0093] S10: Use a small medicine spoon to take a small amount of high-purity aluminum powder and fill it into a high-purity titanium block, compact it with a manual powder briquette, put it into a glow discharge mass spectrometer for detection, perform 5 parallel detections, and save the detection data (detection The data is shown in Table 1), and the average value of the detection results is calculated (the average value is shown in Table 1).

[0094] S20: Weigh 0.0334g graphene oxide (sponge sample), place the sample in a vacuum drying oven for pretreatment for 10h, after the pretreatment is completed, take it out, weigh it, record the mass of the sample after the pretreatment is 0.03231g, and then Put it into a 15cm agate crucible, grind for 20 minutes, then weigh 0.9671g of high-purity aluminum powder, put it into the agate crucible, and grind it for 45 minutes. After the two are evenly mixed, a powder sample is obtained.

[0095]S30: Use a small medicine spoon to take a s...

Embodiment 3

[0098] S20: Use a small medicine spoon to take a small amount of high-purity aluminum powder and fill it into a high-purity titanium block, compact it with a manual powder briquette, put it into a glow discharge mass spectrometer for detection, perform 5 parallel detections, and save the detection data (detection The data is shown in Table 4), and the average value of the detection results is calculated (the average value is shown in Table 4).

[0099] S20: Weigh 0.1034g of graphene oxide (powder sample), place the sample in a vacuum drying oven for pretreatment for 8h, after the pretreatment is completed, take it out, weigh it, record the mass of the sample after the pretreatment is 0.1001g, and place it again Put it into a 15cm agate crucible, grind it for 10 minutes, then weigh 0.8988g of high-purity aluminum powder, put it into the agate crucible, and grind it for 35 minutes. After the two are evenly mixed, a powder sample is obtained.

[0100] S30: Use a small medicine sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com