Waterlogging prevention terminal box

A terminal box and anti-waterlogging technology, which is applied in the direction of electrical components, substation/power distribution device shell, substation/switch layout details, etc., can solve the problems of secondary equipment failure, easy water ingress in terminal box, etc., and avoid equipment failure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

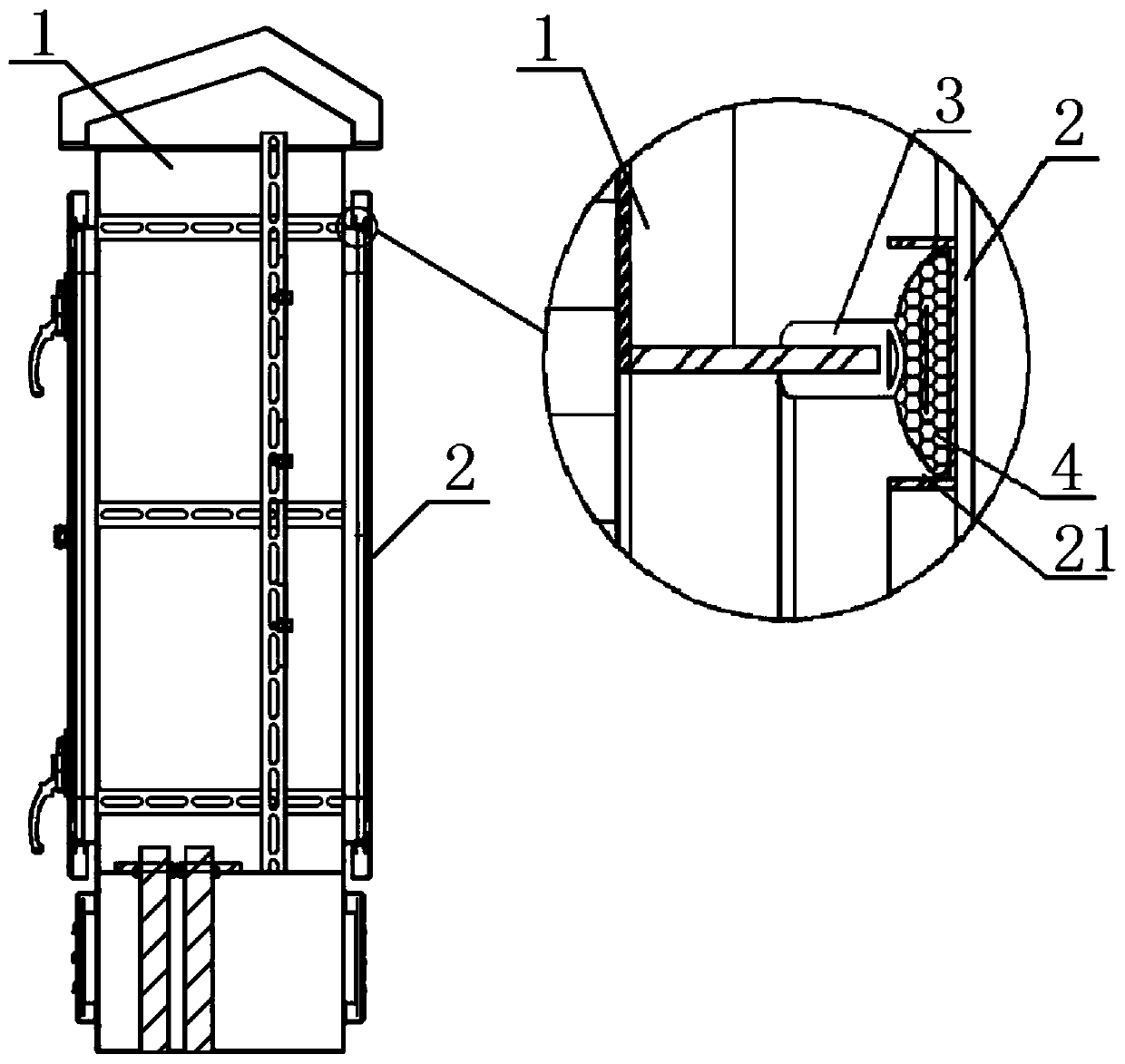

[0027] This embodiment proposes a waterlogging-proof terminal box, such as figure 1 Shown is a schematic structural view of the waterlogging-proof terminal box of this embodiment.

[0028] This embodiment proposes that the anti-waterlogging terminal box includes a box body 1 and a box door 2, the box body 1 is provided with a door frame, and a first sealing strip 3 is arranged around the door frame of the box body. A second sealing strip 4 is provided on the position where the door 2 is attached to the first sealing strip 3 , and a sealing strip slot 21 is opened on the box door 2 , and the second sealing strip 4 is arranged in the sealing strip slot 21 .

[0029] In this embodiment, the first sealing strip 3 is a U-shaped bubble sealing strip, the second sealing strip 4 is a D-shaped sealing strip, and the compression range of the first sealing strip 3 and the second sealing strip 4 is greater than 6 mm.

[0030] In this embodiment, the box body 1 and the box door 2 are conn...

Embodiment 2

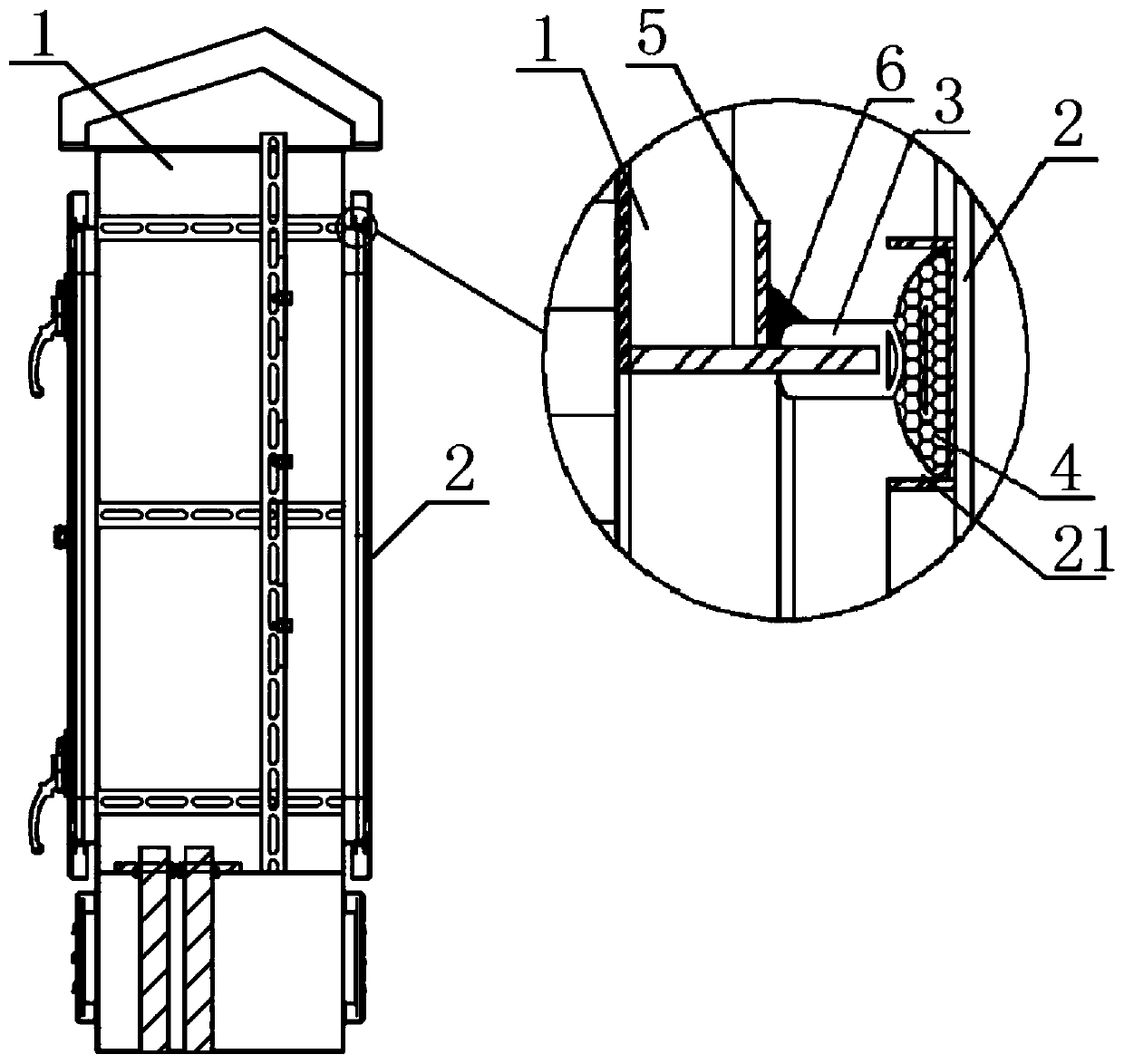

[0034] The waterlogging-proof terminal box proposed in this embodiment is based on the waterlogging-proof terminal box proposed in Example 1, and a water barrier is provided on the door frame of the box body 1 and on the side of the first sealing strip 3 away from the box door 2 5.

[0035] Such as figure 2 Shown is a schematic structural view of the waterlogging-proof terminal box of this embodiment.

[0036] In this embodiment, on the door frame of the box body 1 and on the side of the first sealing strip 3 away from the box door 2, a water baffle 5 is provided, and a waterproof seal is installed between the water baffle 5 and the first sealing strip 3. The glass glue 6 can effectively block the stagnant water and prevent the stagnant water between the box door 2 and the box body 1 from flowing into the box body 1 .

[0037] In the specific implementation process, the first sealing strip 3 and the second sealing strip 4 arranged between the box body 1 and the box door 2 a...

Embodiment 3

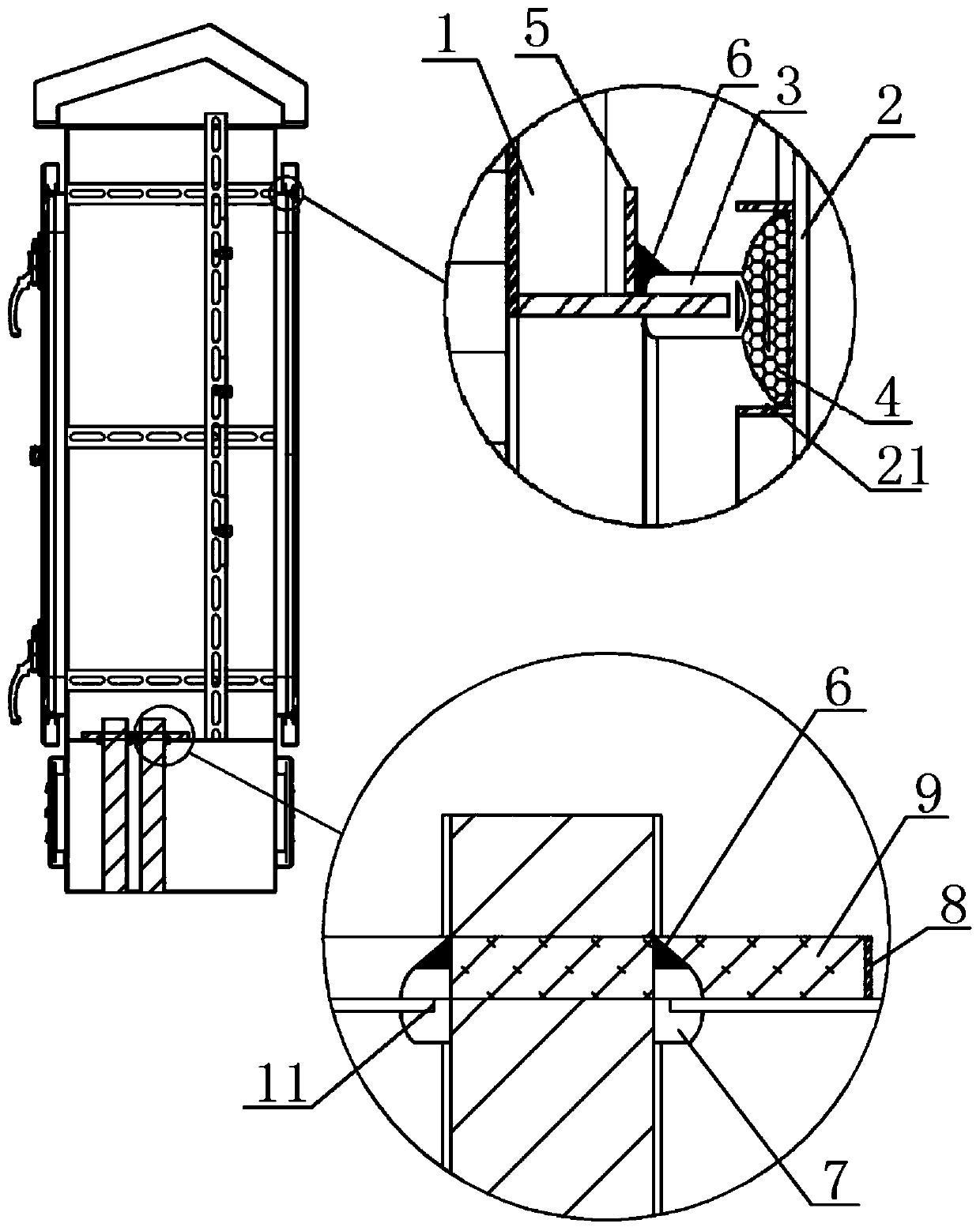

[0039] The waterlogging-proof terminal box proposed in this embodiment is based on the waterlogging-proof terminal box proposed in Example 1 or Example 2, and a two-way protection coil 7 is added at the position of the cable inlet hole 11 opened at the bottom of the box body 1 . Such as image 3 Shown is a schematic structural view of the waterlogging-proof terminal box of this embodiment.

[0040] In this embodiment, the bottom of the box body 1 is provided with several cable inlet holes 11, and a bidirectional protective coil 7 is arranged between the cable inlet hole 11 and the inserted cable, and a seal between the inserted cable and the bidirectional protective coil 7 Plug is provided with waterproof glass glue 6. In addition, a surrounding edge 8 is vertically arranged on the bottom plate of the box body 1 and around the outer periphery of the cable inlet hole 11, and the surrounding edge is filled with a sealing material 9 to achieve a zero-gap sealing effect between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com