Sugar-free syrup and preparation method thereof

A sugar-free syrup technology, applied in food science, application, food ingredients, etc., can solve the problems of sugar-free syrup stability defects and achieve excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

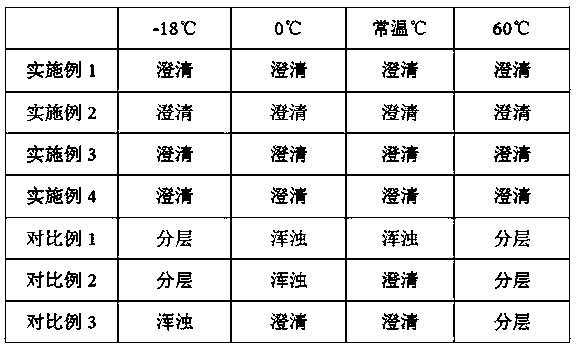

Examples

Embodiment 1

[0024] A sugar-free syrup, the sugar-free syrup is made of the following raw materials in parts by weight: 38 parts of erythritol, 6 parts of maltitol, 0.8 part of steviol glycoside, 0.2 part of sucrose fatty acid ester, and 0.02 part of potassium sorbate , 0.6 part of glucosyl steviol glycoside, 0.1 part of gum arabic, 0.06 part of citric acid, 0.12 part of sodium citrate, 50 parts of deionized water.

[0025] The preparation method of described sugar-free syrup comprises the following steps:

[0026] (1) Add erythritol and maltitol into deionized water, heat to 70°C, and stir evenly;

[0027] (2) Heat to 110°C, add steviol glycoside, sucrose fatty acid ester, food flavoring, food colloid, and stir evenly;

[0028] (3) Add citric acid and sodium citrate to adjust the pH, and stir well;

[0029] (4) Cool down to 50°C, add potassium sorbate, and stir evenly to obtain the sugar-free syrup.

[0030] In the stirring step, the stirring rate is 500 rpm.

Embodiment 2

[0032] A sugar-free syrup, the sugar-free syrup is made of the following raw materials in parts by weight: 25 parts of erythritol, 4 parts of maltitol, 0.5 part of steviol glycoside, 0.1 part of sucrose fatty acid ester, and 0.01 part of potassium sorbate , 0.3 part of glucosyl steviol glycoside, 0.06 part of gum arabic, 0.04 part of citric acid, 0.06 part of sodium citrate, 40 parts of deionized water.

[0033] The preparation method of described sugar-free syrup comprises the following steps:

[0034] (1) Add erythritol and maltitol into deionized water, heat to 70°C, and stir evenly;

[0035] (2) Heat to 110°C, add steviol glycoside, sucrose fatty acid ester, food flavoring, food colloid, and stir evenly;

[0036] (3) Add citric acid and sodium citrate to adjust the pH, and stir well;

[0037] (4) Cool down to 50°C, add potassium sorbate, and stir evenly to obtain the sugar-free syrup.

[0038] In the stirring step, the stirring rate is 500 rpm.

Embodiment 3

[0040] A sugar-free syrup, which is made of the following raw materials in parts by weight: 50 parts of erythritol, 10 parts of maltitol, 1 part of steviol glycoside, 0.4 part of sucrose fatty acid ester, and 0.06 part of potassium sorbate , 0.9 part of glucosyl steviol glycoside, 0.15 part of gum arabic, 0.1 part of citric acid, 0.18 part of sodium citrate, 60 parts of deionized water.

[0041] The preparation method of described sugar-free syrup comprises the following steps:

[0042] (1) Add erythritol and maltitol into deionized water, heat to 70°C, and stir evenly;

[0043] (2) Heat to 110°C, add steviol glycoside, sucrose fatty acid ester, food flavoring, food colloid, and stir evenly;

[0044] (3) Add citric acid and sodium citrate to adjust the pH, and stir well;

[0045] (4) Cool down to 50°C, add potassium sorbate, and stir evenly to obtain the sugar-free syrup.

[0046] In the stirring step, the stirring rate is 500 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com