Printed wiring board device

A technology for printed circuit boards and substrates, applied in the directions of printed circuits, printed circuits, circuit devices, etc., can solve the problems of high manufacturing price and difficult application, and achieve the effect of suppressing electromagnetic radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Referring to the accompanying drawings, the detailed description is the best embodiment for implementing the present invention.

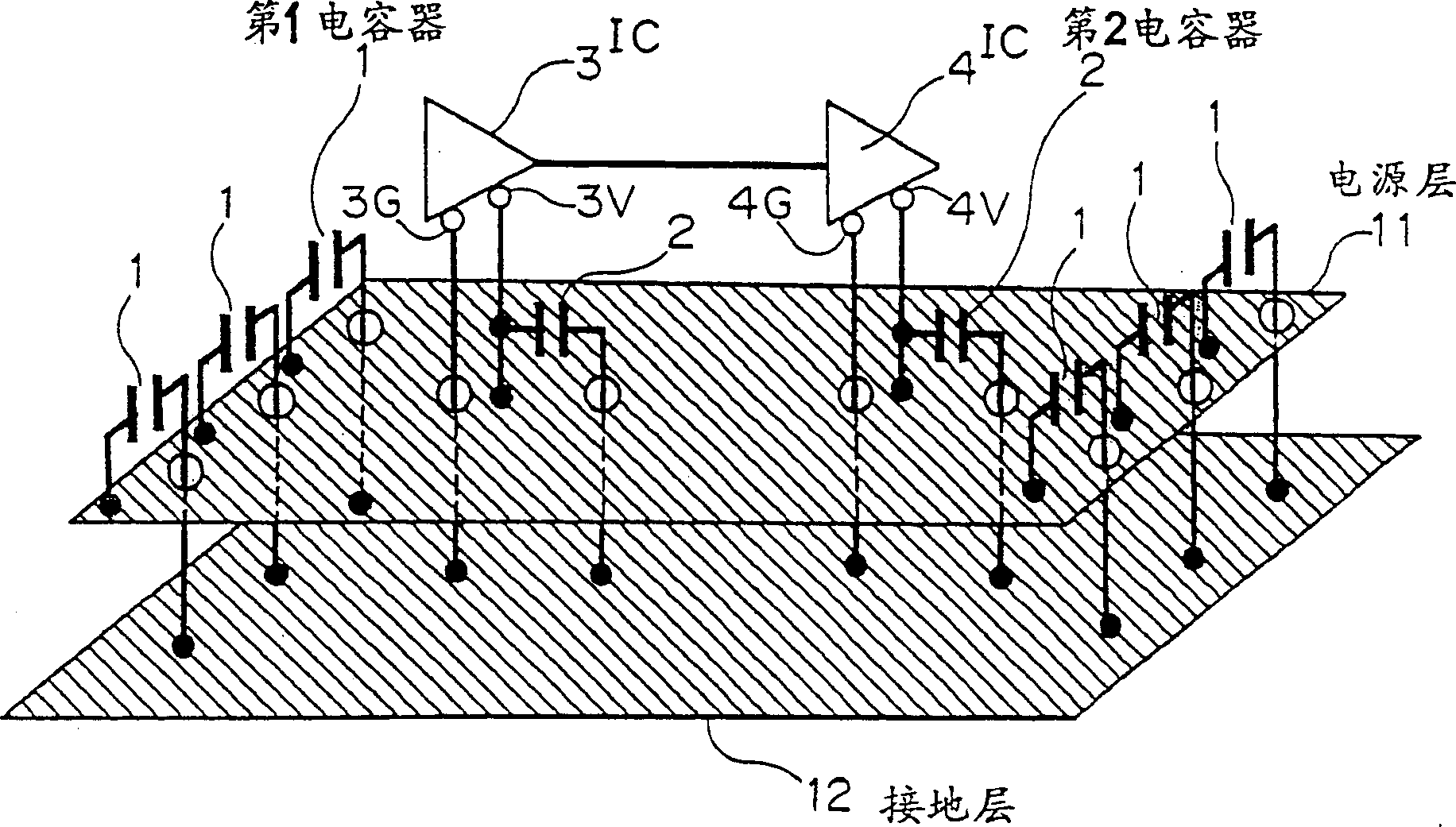

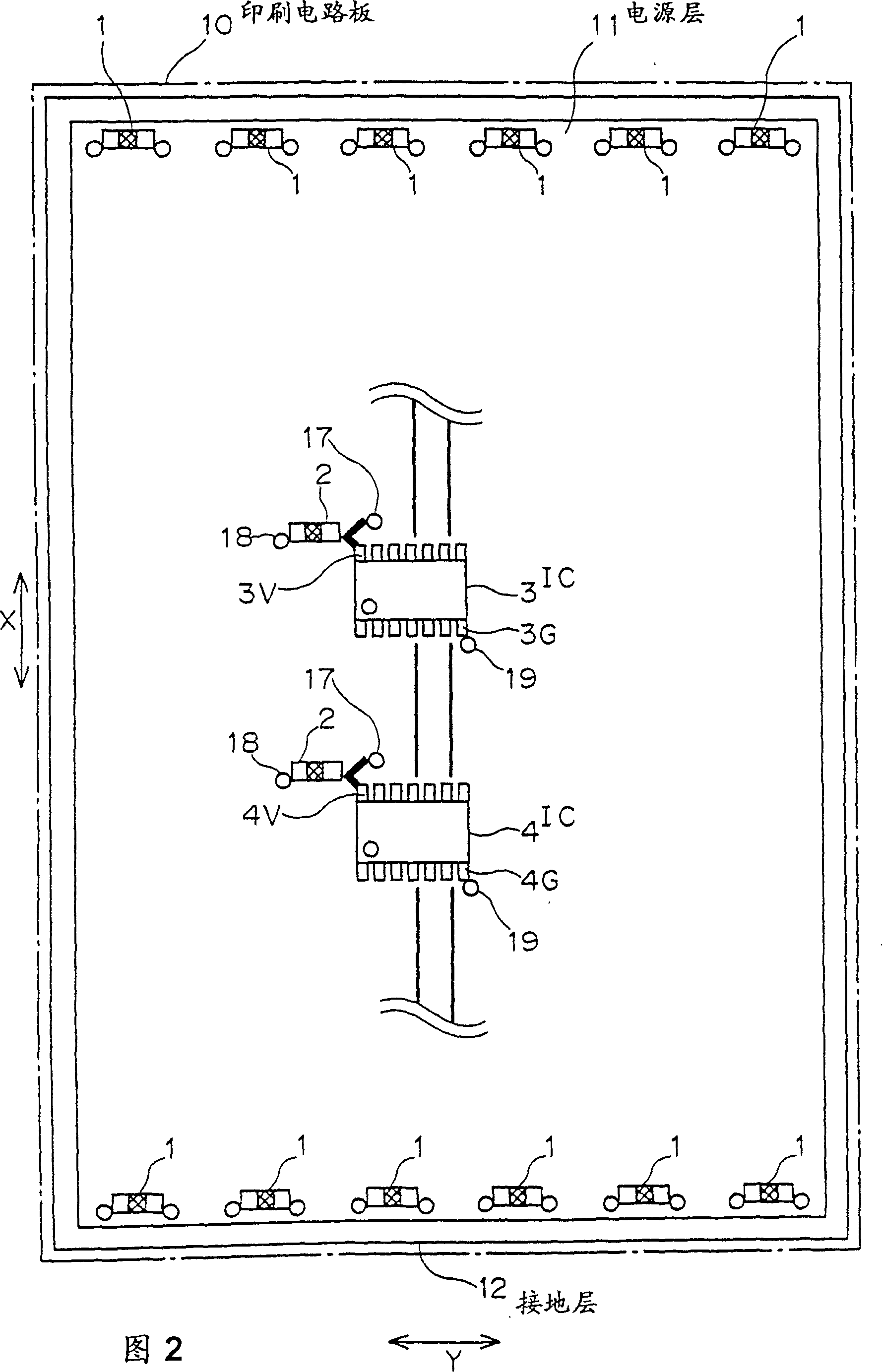

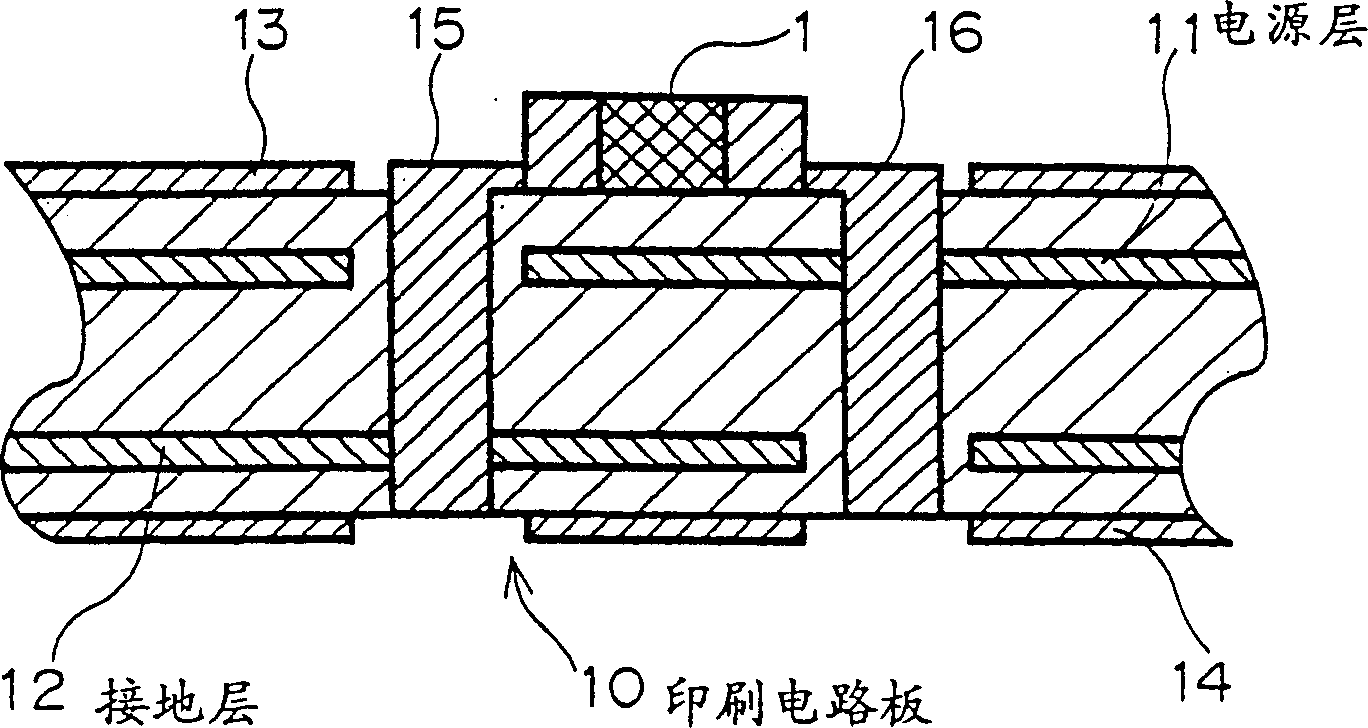

[0057] figure 1 ~ Fig. 4 shows an example of the printed circuit board device of the present invention. figure 1 The schematic composition of the device is given, and Fig. 2 is a schematic plan view of the device, image 3 Showing the cross-sectional configuration of the configuration portion of the first capacitor, FIG. 4 is a schematic plan view of a digital integrated circuit as an active element and a configuration portion of the second capacitor.

[0058] The printed circuit board 10 of the printed circuit board device of this example is as image 3 Shown is a 4-layer printed circuit board having a power layer 11 , a ground layer 12 , a graphics layer 13 and a graphics layer 14 . It is also acceptable to have one or more graphic layers between the power supply layer 11 and the ground layer 12 .

[0059] In addition, the printed cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com