Uniform mixing type concrete stirring device

A technology of uniform mixing and mixing device, applied in cement mixing device, clay preparation device, mixing plant, etc., can solve problems such as unfavorable construction work, concrete caking, troublesome moving process, etc. , Increase the effect of stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

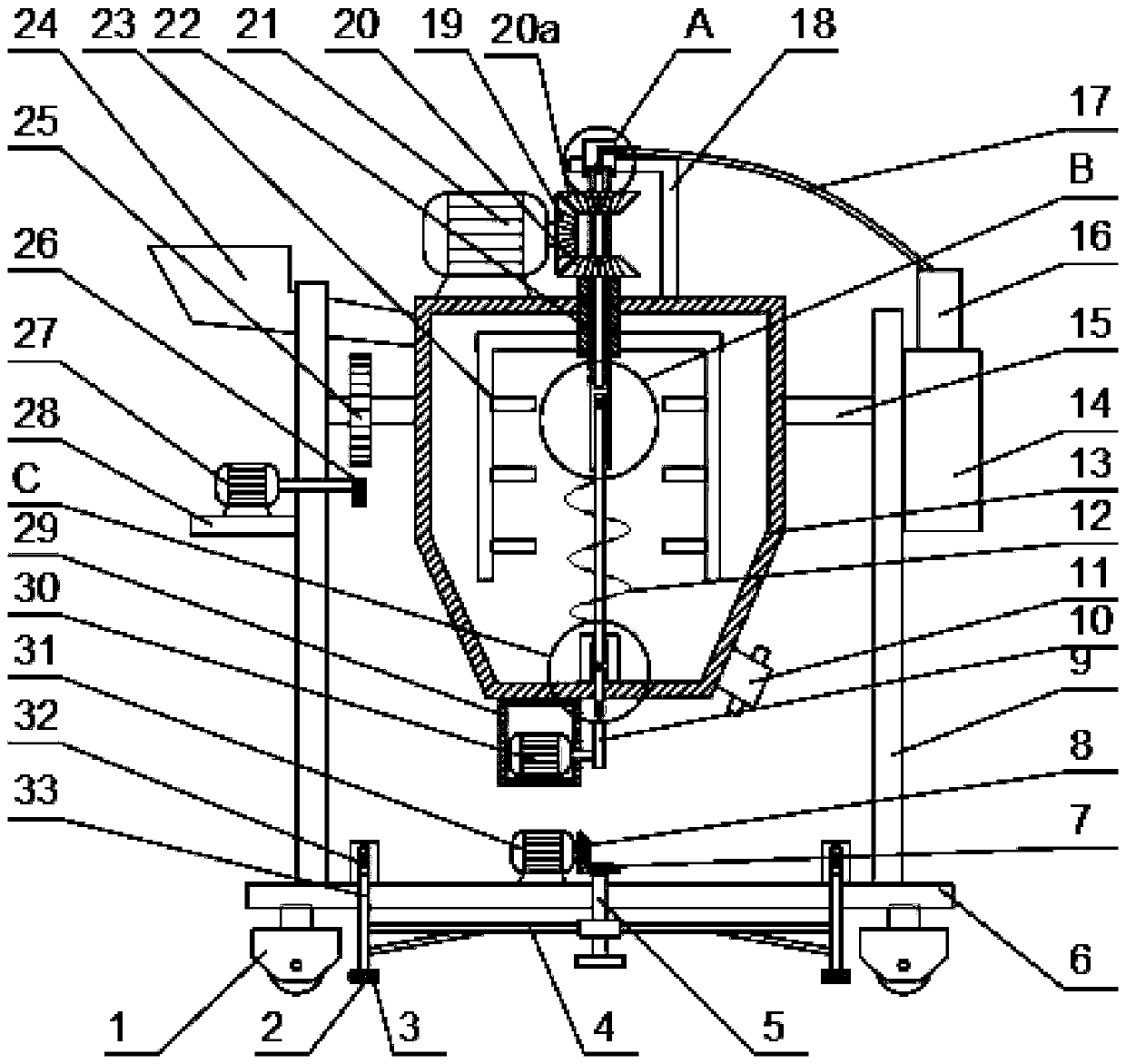

[0030] see figure 1 , a uniformly mixed concrete mixing device, comprising a first motor 21, a second motor 27, a third motor 30, a fourth motor 31, a water pump 16 and a bottom plate 6, and the output end of the fourth motor 31 is fixedly connected to the second bevel gear 8. The second bevel gear 8 meshes with the first bevel gear 7. The lower end of the bottom plate 6 is fixedly connected to several rollers 1. The rollers 1 are universal rollers. The center of the bottom plate 6 is rotated to connect the threaded column 5, and the upper end of the threaded column 5 is fixedly connected. The first bevel gear 7, the threaded column 5 are threadedly connected with the connecting plate 4, and several supporting legs 33 are fixedly connected to the outside of the connecting plate 4, the supporting legs 33 are set, the fourth motor 31 is controlled to rotate, and the connecting plate 4 is moved up and down to realize the support. The stable support of the device by the legs 33 av...

Embodiment 2

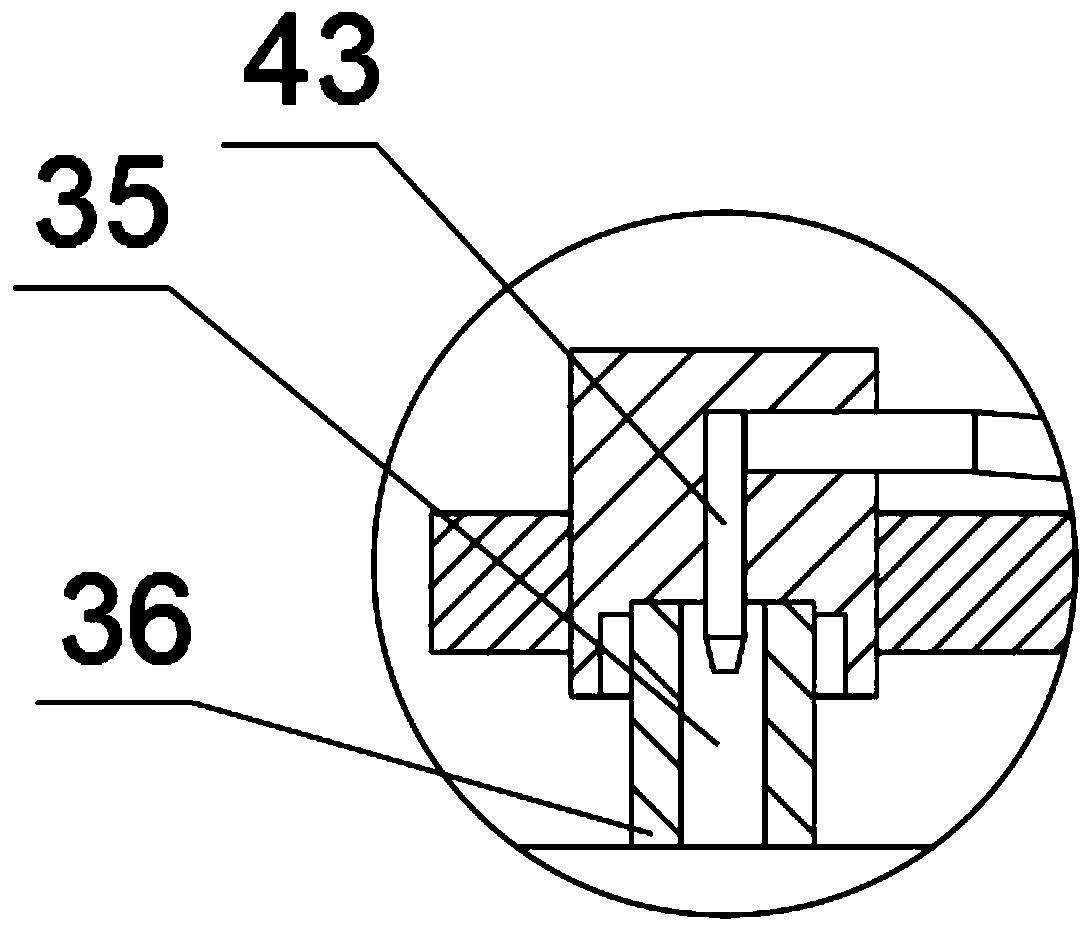

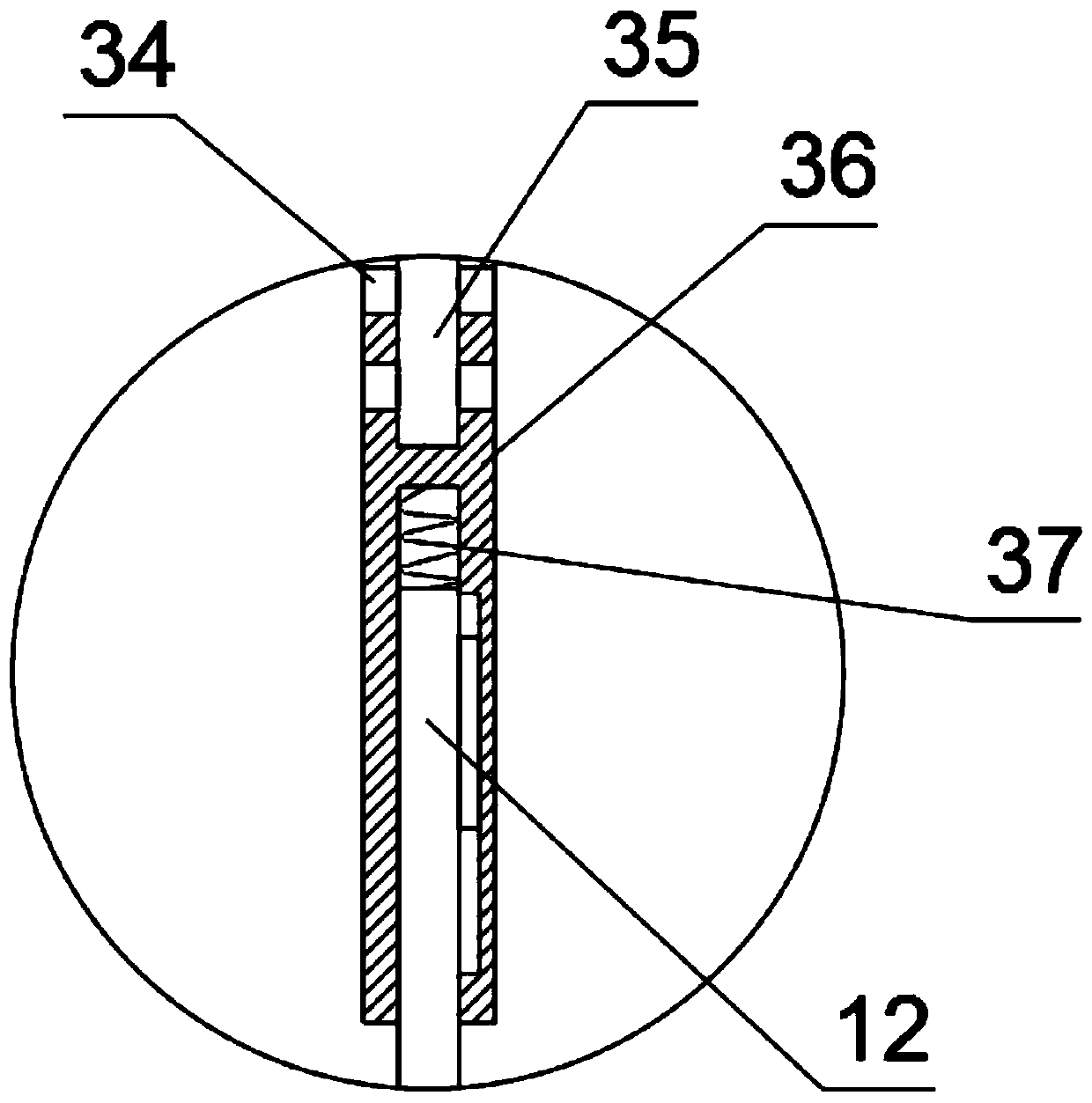

[0033] see figure 1 The difference between this embodiment and the above-mentioned embodiment 1 is that a seal 39 is provided at the connection position between the spacer 42 and the rotating shaft 36, and the sealing member 39 prevents the concrete from being carried out when the rotating shaft 36 moves up and down.

[0034] The working principle of the present invention is: when the uniformly mixed concrete mixing device needs to be mixed uniformly, the device is moved by the installed roller 1, and after moving to a suitable position, the fourth motor 31 is opened to make the screw thread When the column 5 rotates, the threaded column 5 will move the connecting plate 4 down, and the fixed legs 33 of the connecting plate 4 will support the device, so that the device can be stably fixed on the ground without slipping, and then through the feed hopper 24, The concrete raw material is input into the mixing tank 13, the water pump 16 is turned on, and the water in the water tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com