Self-repairable epoxy resin and preparation method thereof

An epoxy resin and self-repair technology, which is applied in the field of self-repairable epoxy resin and its preparation, can solve the problems of poor mechanical properties, low repair efficiency, long repair time, etc., and achieve good self-repair function and self-repair efficiency High and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

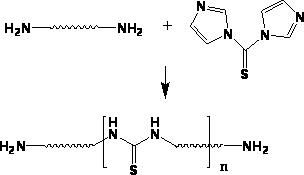

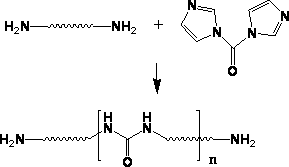

[0049] (A) Mix 30g of N,N'-thiocarbonyldiimidazole, 10g of 1,2-bis(2-aminoethoxy)ethane, and 20g of ethanol, and react at 40°C for 4h to obtain a pre-reaction liquid;

[0050] (B) Stir and mix the pre-reaction solution with 100g of epoxy resin (glycidyl ester type epoxy resin) evenly; at 50°C, stir and react for 100 min, and then vacuum defoam to obtain a self-healing epoxy resin .

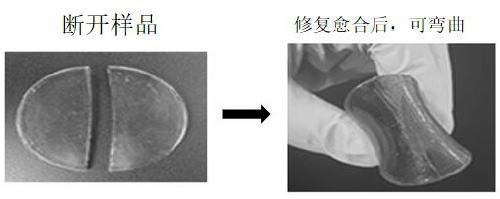

[0051] as attached figure 1 As shown, the resulting self-healing epoxy was disconnected and re-contacted, and the material healed and repaired within 2 minutes. It can be seen that after a short period of room temperature exposure, efficient healing can be achieved.

Embodiment 2

[0053] (A) Mix 40 g of N,N'-thiocarbonyldiimidazole, 10 g of triethylene glycol bis(2-aminoethyl) ether, and 5 g of methanol, and react at 60°C for 4 hours to obtain a pre-reaction solution;

[0054] (B) Stir and mix the pre-reaction solution with 100g of epoxy resin (bisphenol A epoxy resin); at 40°C, stir and react for 80 min, followed by vacuum defoaming to obtain a self-healing epoxy resin .

[0055] The resulting self-healing epoxy was disconnected and re-contacted, and the material healed within a minute. It can be seen that after a short period of room temperature exposure, efficient healing can be achieved.

Embodiment 3

[0057] (A) Mix 10 g of N,N'-thiocarbonyldiimidazole, 2 g of ethylene glycol mono(2-aminoethyl) ether, and 10 g of n-butanol, and react at 40°C for 3 hours to obtain a pre-reaction solution ;

[0058] (B) Stir and mix the pre-reaction solution with 100g of epoxy resin (bisphenol F epoxy resin); stir and react for 120 min at 60°C, and then vacuum defoam to obtain a self-healing epoxy resin .

[0059]The resulting self-healing epoxy was disconnected and re-contacted, and the material healed within 4 minutes. It can be seen that after a short period of room temperature exposure, efficient healing can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com