Diester core-based lubricating oil composition for diesel engine and preparation method thereof

A lubricating oil composition and diesel engine technology, applied in the field of lubricating oil, can solve the problems of reducing the degree of engine wear and achieve the effects of reducing friction and wear, low oil consumption, and reducing sludge and carbon deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

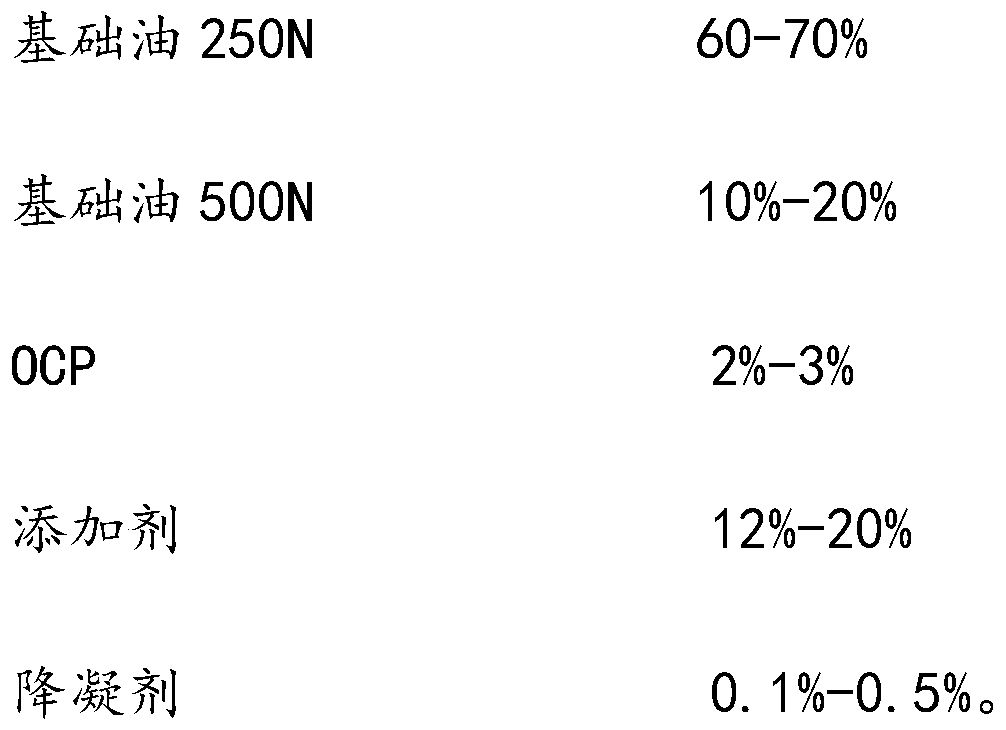

[0033] The diesel engine lubricating oil composition based on the diester core of this embodiment is composed of the following components by weight percentage:

[0034]

[0035] The preparation method of the diesel engine lubricating oil composition based on the diester core of the present embodiment is as follows:

[0036] (1) Weigh base oil 250N and base oil 500N respectively according to the proportioning weight, put them into the blending tank, and stir for 35min at a stirring speed of 180rpm;

[0037] (2) Weigh the additive 12210 according to the proportioning weight and put it into the blending tank, and heat the blending tank temperature to 45°C;

[0038] (3) Weigh base oil 100N and ethylene-propylene rubber according to the proportioning weight, and when heated to 100°C, put them into the blending tank;

[0039] (4) Weigh pour point depressant 1-248 by weight and put it into the blending tank, and heat the blending tank to 56°C, and stir at this temperature for 2h;...

Embodiment 2

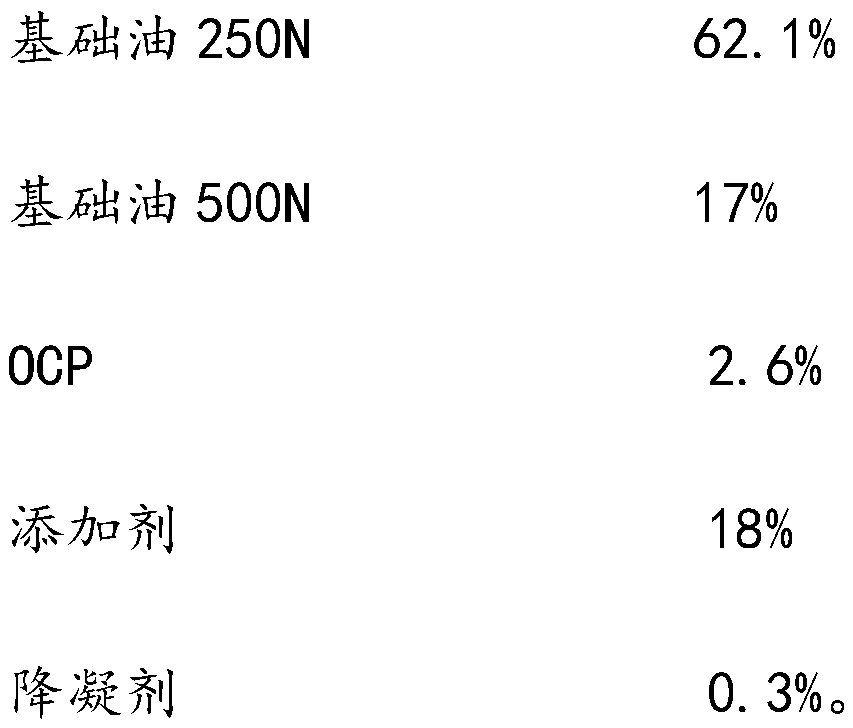

[0043] The diesel engine lubricating oil composition based on the diester core of this embodiment is composed of the following components by weight percentage:

[0044]

[0045] The preparation method of the diesel engine lubricating oil composition based on the diester core of the present embodiment is as follows:

[0046] (1) Weigh base oil 250N and base oil 500N respectively according to the proportioning weight, put them into the blending tank, and stir for 35min at a stirring speed of 180rpm;

[0047] (2) Weigh the additive 12210 according to the proportioning weight and put it into the blending tank, and heat the blending tank temperature to 45°C;

[0048] (3) Weigh base oil 100N and ethylene-propylene rubber according to the proportioning weight, and when heated to 100°C, put them into the blending tank;

[0049] (4) Weigh pour point depressant 1-248 by weight and put it into the blending tank, heat the blending tank to 58°C, and stir at this temperature for 1.8h; ...

Embodiment 3

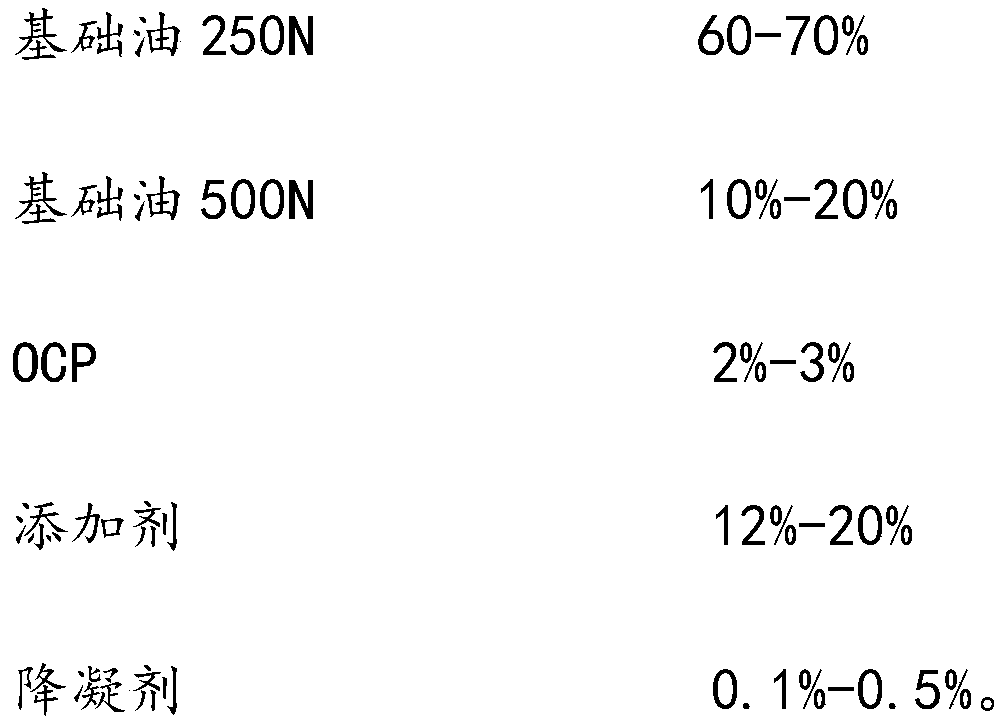

[0053] The diesel engine lubricating oil composition based on the diester core of this embodiment is composed of the following components by weight percentage:

[0054]

[0055]

[0056] The preparation method of the diesel engine lubricating oil composition based on the diester core of the present embodiment is as follows:

[0057] (1) Weigh base oil 250N and base oil 500N respectively according to the proportioning weight, put them into the blending tank, and stir for 35min at a stirring speed of 180rpm;

[0058] (2) Weigh the additive 12210 according to the proportioning weight and put it into the blending tank, and heat the blending tank temperature to 45°C;

[0059] (3) Weigh base oil 100N and ethylene-propylene rubber according to the proportioning weight, and when heated to 100°C, put them into the blending tank;

[0060] (4) Weigh pour point depressant 1-248 by weight and put it into the blending tank, heat the blending tank to 55°C, and stir at this temperature f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com