Steam generator and water level control method thereof as well as steam cooking device

A technology of steam generator and water level control, which is applied in the direction of steam generation method, steam generation, steam cooking utensils, etc., and can solve problems such as dry burning, user inconvenience, and rust caused by electrochemical reaction of water level probes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

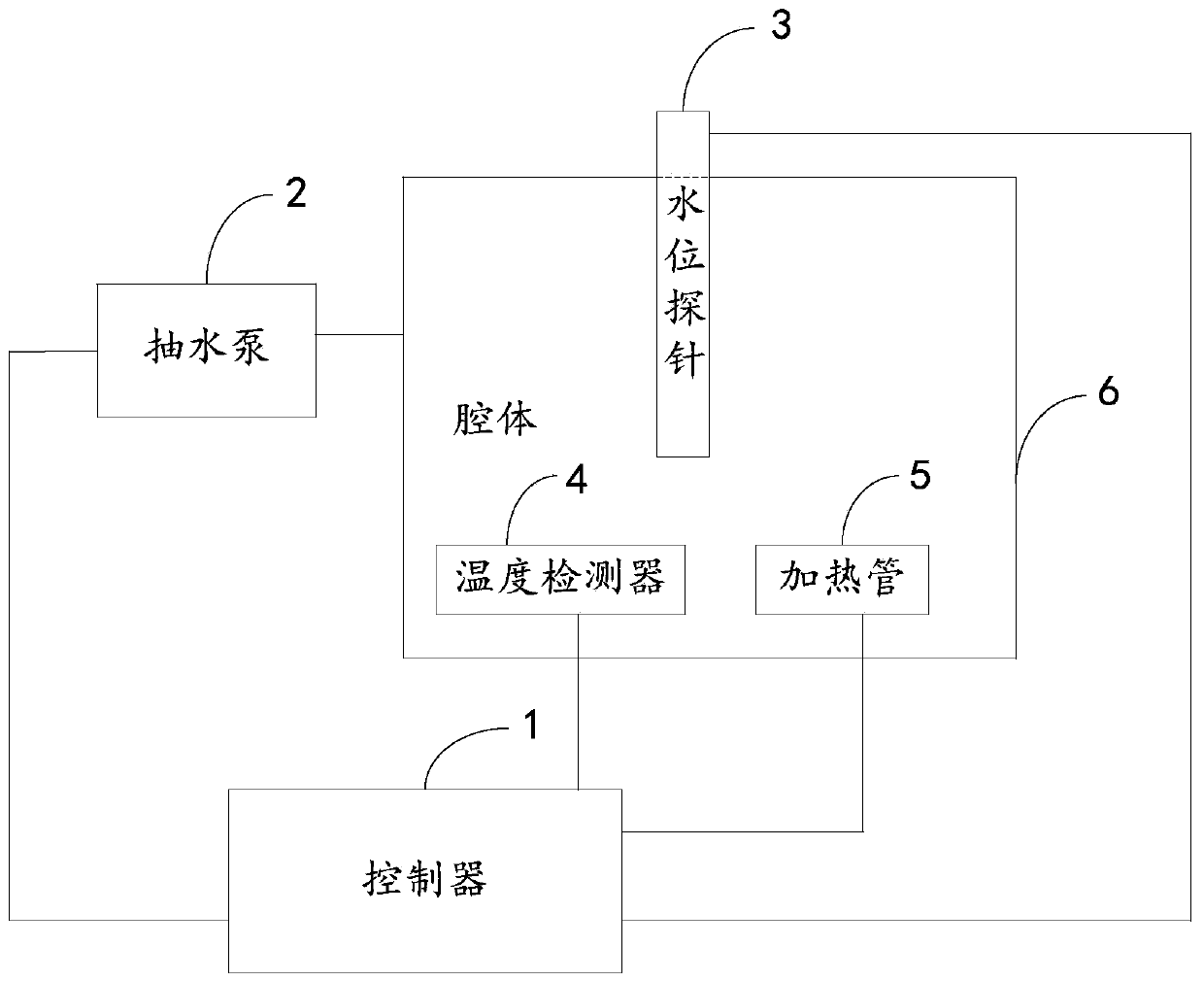

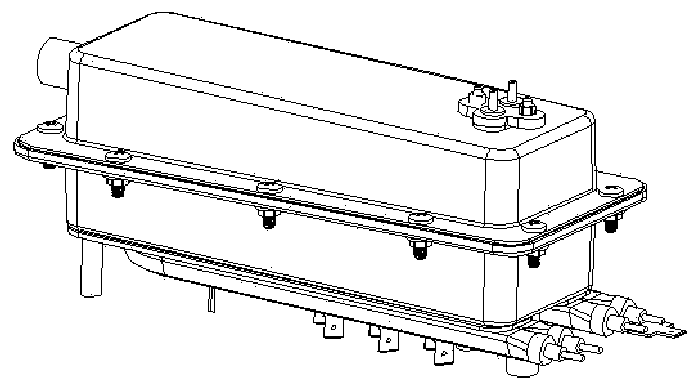

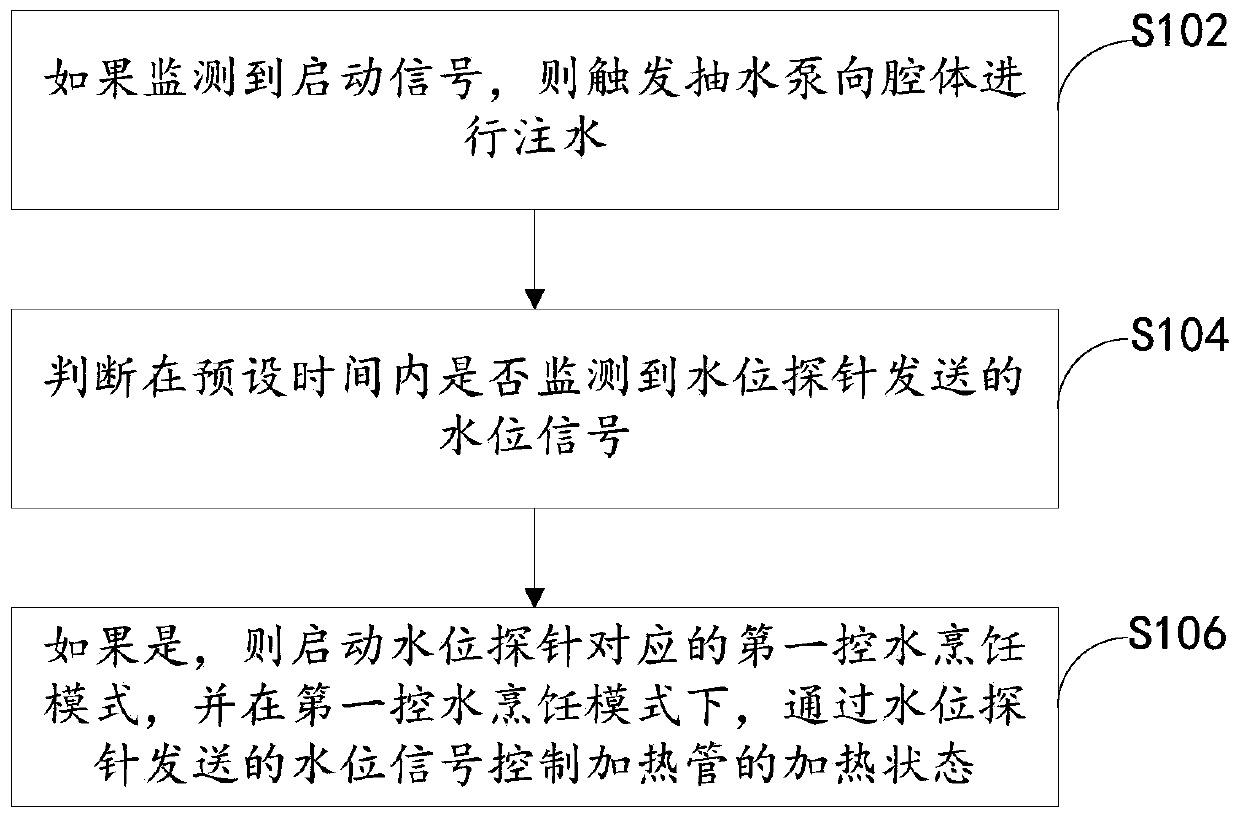

[0057] An embodiment of the present invention provides a water level control method for a steam generator, wherein, such as figure 1 As shown, the steam generator includes a controller 1 and a water pump 2 connected to the controller 1, a water level probe 3, a temperature detector 4 and a heating pipe 5, and the water level probe 3, the temperature detector 4 and the heating pipe 5 are arranged on In the cavity 6 of the steam generator, in practical applications, common steam generators such as figure 2 shown. exist figure 1 on the basis of image 3 A flow chart of a water level control method for a steam generator provided by an embodiment of the present invention, the method is applied to the controller 1 of the steam generator, such as image 3 As shown, the method includes the following steps:

[0058] Step S102, if the start signal is detected, trigger the water pump to inject water into the cavity;

[0059] In practical application, the water level probe 3 extends...

Embodiment 2

[0102] On the basis of the above-mentioned embodiments, an embodiment of the present invention also provides a steam generator, wherein the steam generator includes a controller, a water pump connected to the controller, a water level probe, a temperature detector and a heating pipe, and the water level The probe, temperature detector and heating tube are arranged in the cavity of the steam generator. Figure 7 The schematic diagram of another kind of steam generator provided for the embodiment of the present invention, as Figure 7 As shown, the steam generator also includes:

[0103] A trigger module 10, configured to trigger the water pump to inject water into the chamber if a start signal is detected;

[0104] Judging module 20, used to judge whether the water level signal sent by the water level probe is monitored within the preset time;

[0105] The starting module 30 is configured to start the first water-controlled cooking mode corresponding to the water level probe,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com