Waveguide port cavity dielectric filter

A dielectric filter and waveguide port technology, applied in the field of filters, can solve the problems of out-of-band suppression and temperature drift limitation, high quality factor, unobtainable, etc., and achieve excellent performance indicators, good electrical performance, and facilitate mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

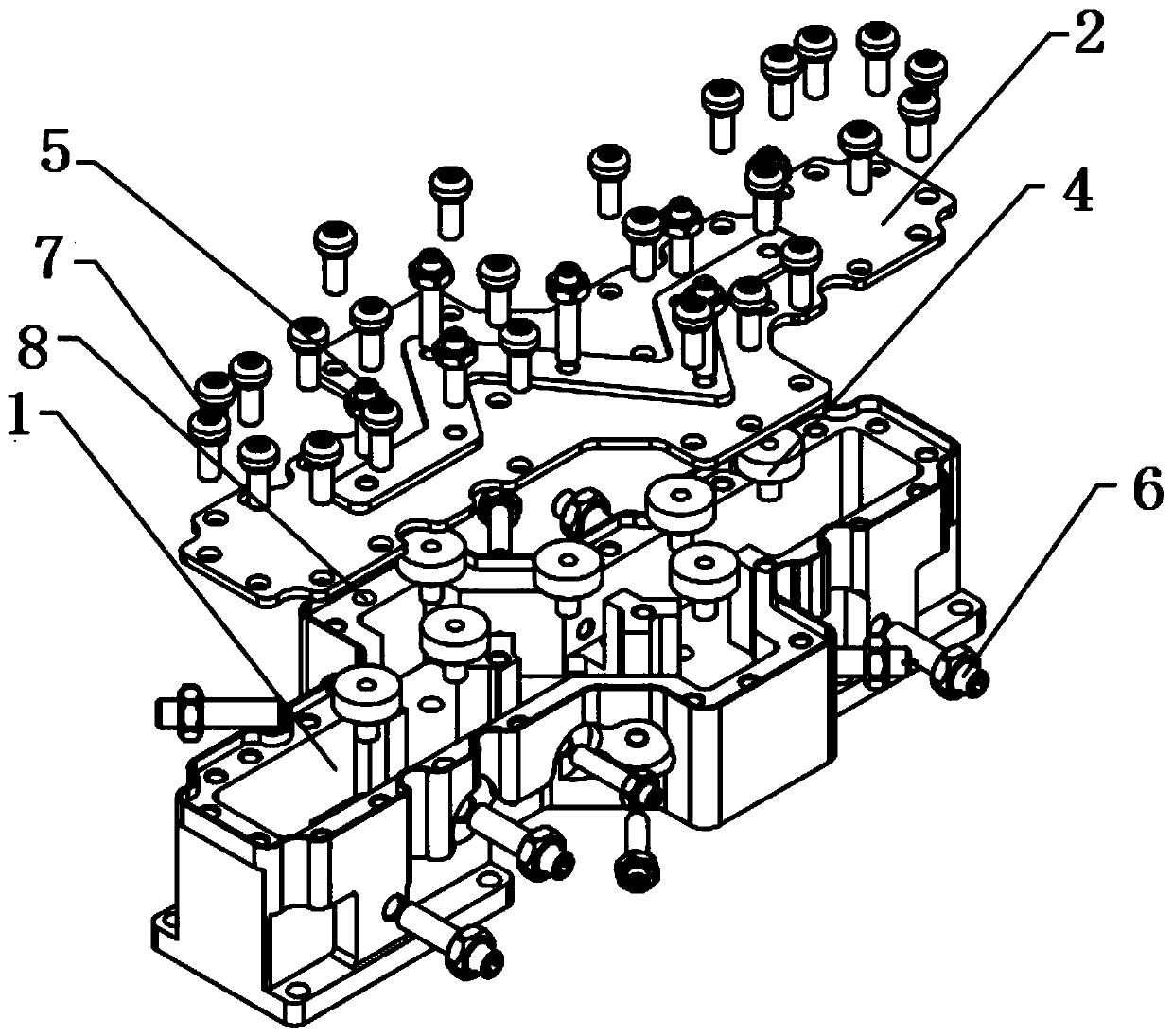

[0033] A waveguide cavity dielectric filter, including a cavity 1, a cover plate 2, several dielectric resonators 4, several frequency tuning screws 5 and several coupling tuning screws 6, there are at least two dielectric resonators 4,

[0034] The upper surface of the cavity 1 is provided with a receiving groove, several dielectric resonators 4 are fixedly arranged at the bottom of the receiving groove, the cover plate 2 is fixedly arranged on the cavity body 1, and the lower ends of several frequency tuning screws 5 pass through the cover plate 2 and extend into the receiving groove , a number of frequency tuning screws 5 are rotationally connected or slidingly connected to the cover plate 2, there is a frequency tuning screw 5 above the dielectric resonator 4, and a number of coupling tuning screws 6 extend transversely through the side wall of the cavity 1 into the accommodation groove, Several coupling tuning screws 6 are rotationally connected or slidingly connected to t...

Embodiment 2

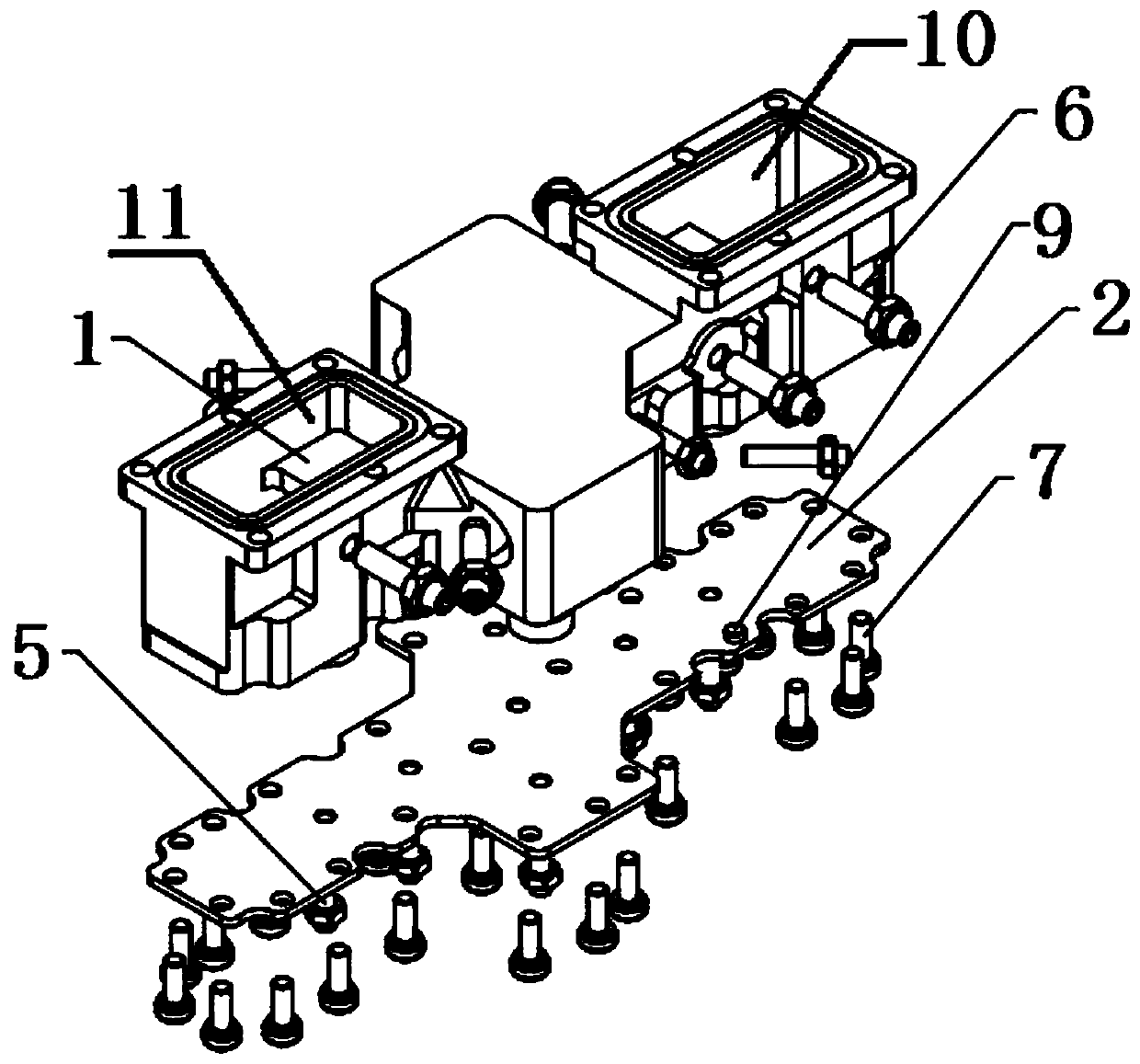

[0053] A waveguide cavity dielectric filter, including a cavity 1, a cover plate 2, several dielectric resonators 4, several frequency tuning screws 5 and several coupling tuning screws 6, there are at least two dielectric resonators 4,

[0054] The upper surface of the cavity 1 is provided with a receiving groove, several dielectric resonators 4 are fixedly arranged at the bottom of the receiving groove, the cover plate 2 is fixedly arranged on the cavity body 1, and the lower ends of several frequency tuning screws 5 pass through the cover plate 2 and extend into the receiving groove , a number of frequency tuning screws 5 are rotationally connected or slidingly connected to the cover plate 2, there is a frequency tuning screw 5 above the dielectric resonator 4, and a number of coupling tuning screws 6 extend transversely through the side wall of the cavity 1 into the accommodation groove, Several coupling tuning screws 6 are rotationally connected or slidingly connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com