Z-axis linear motor quality block shaping mold and assembly method thereof

A mass block and mold technology, applied in the field of motor manufacturing, can solve the problems of reduced maintenance cost, high maintenance cost, low ease of use, etc., and achieve the effect of reducing maintenance cost and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

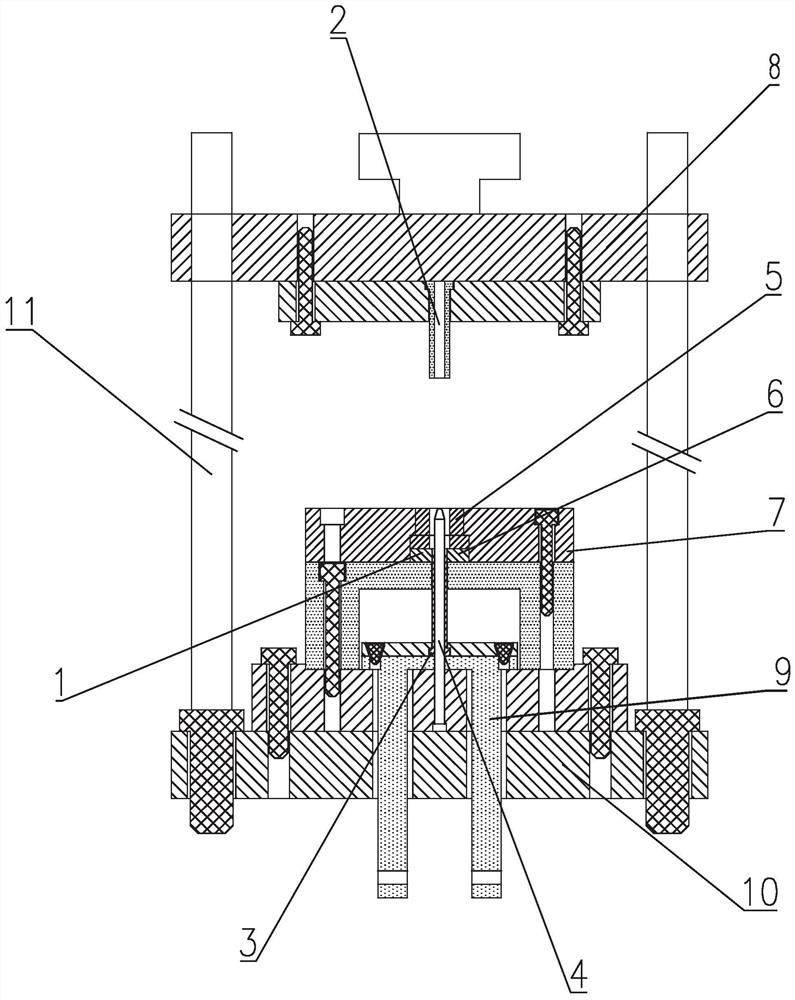

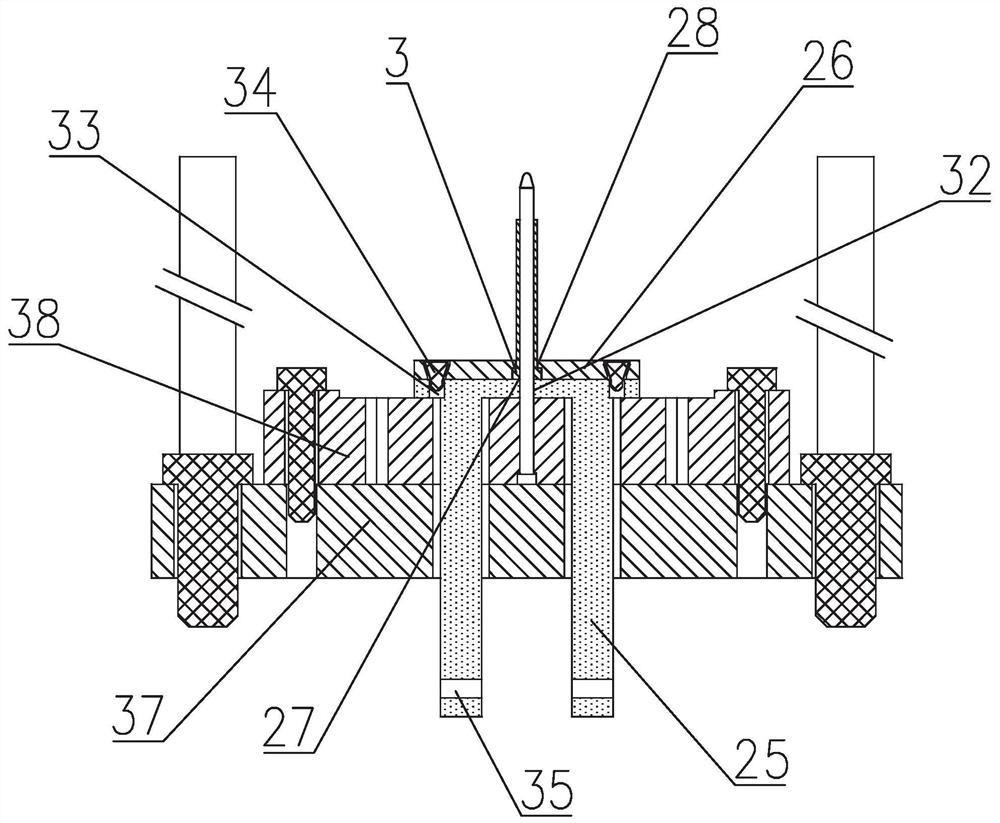

[0034] Such as Figure 1 to Figure 5 As shown, a Z-axis linear motor mass shaping mold includes a mold assembly and a mold base assembly. The mold assembly includes a die 1, an upper punch 2, a lower punch 3 and a mandrel 4. The die is composed of an upper die 5 and a lower die. The die 6 is spliced together, and the mold base assembly includes the die fixing part 7, the upper punch fixing part 8, the lower punch fixing part 9 and the mandrel fixing part 10, and the upper punch fixing part and the mandrel fixing part are positioned together by the guide post 11. Shaft arrangement, the upper punch and the lower punch are arranged at intervals along the length direction of the guide post, the lower punch fixing part, the mandrel fixing part and the upper punch fixing part are all connected with the punching machine; the upper punch fixing part includes the upper punch backing plate connected with the guide post 12 and the upper stamping plate 13 used to fix the upper punch, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com