Assembly line marking equipment

A marking equipment and assembly line technology, applied in welding equipment, welding equipment, laser welding equipment, etc., can solve the problems of position deviation, different heights, and circuit board inclination during marking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

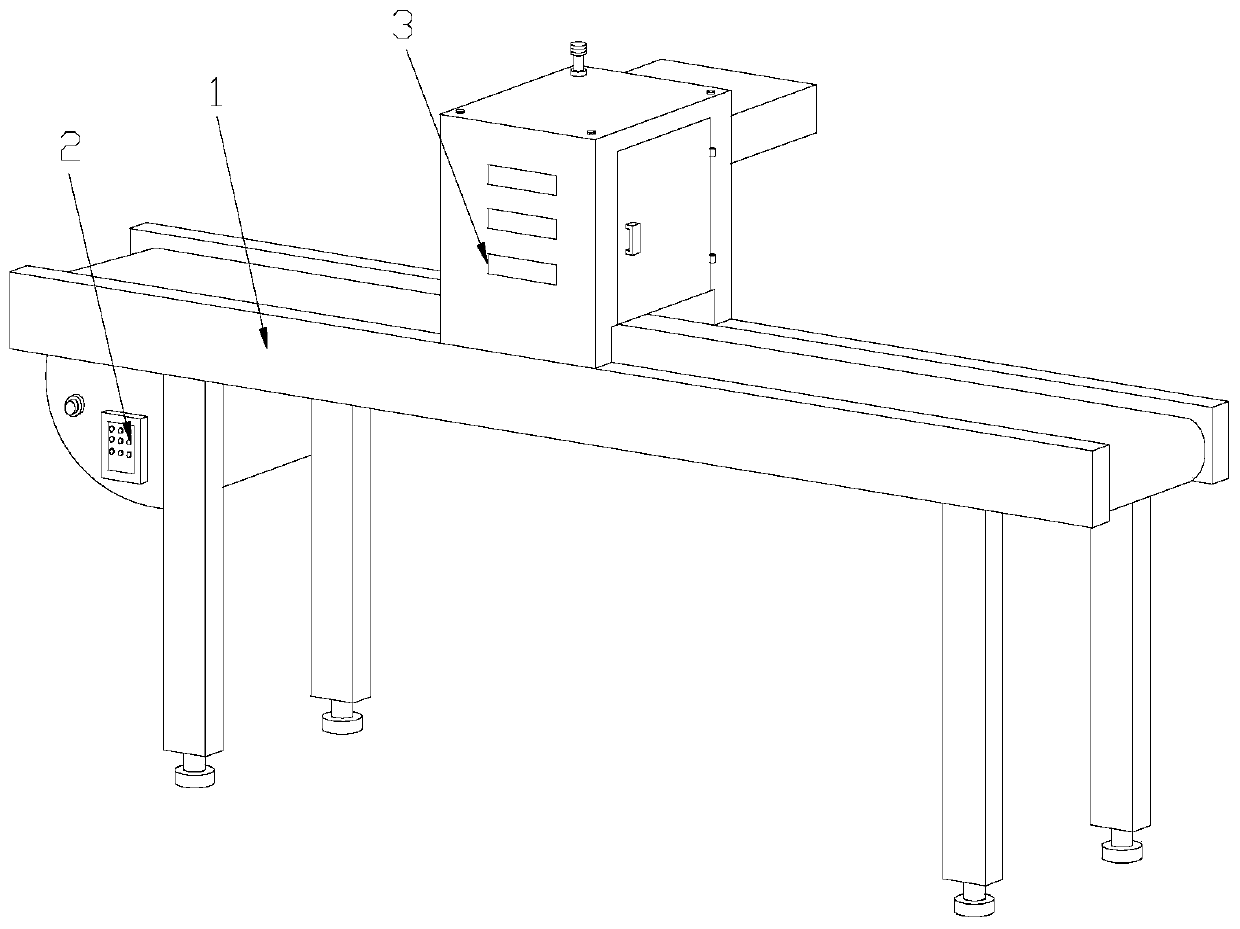

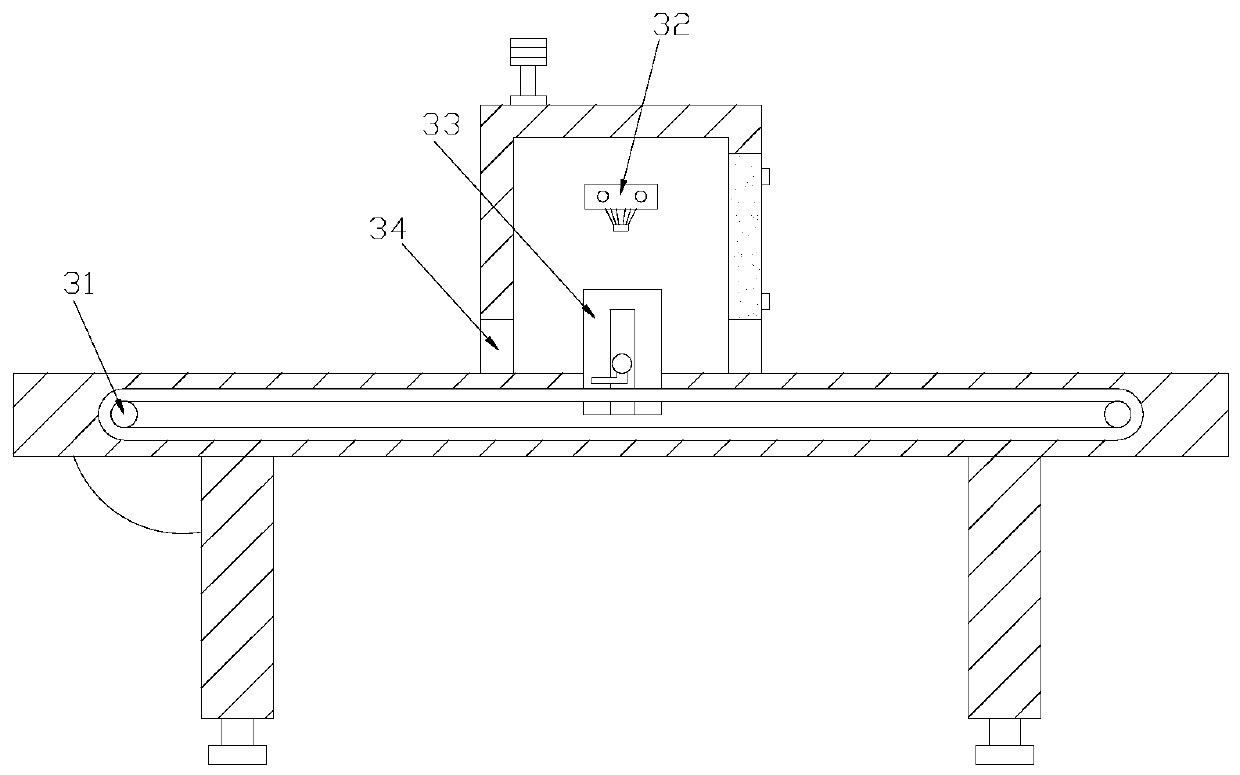

[0027] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiment of the present invention is as follows: its structure comprises bracket 1, control box 2, marking box 3, the bottom of described bracket 1 is welded with control box 2, and described marking box 3 is installed in the top middle of bracket 1, The marking box 3 includes a conveyor belt 31, a laser emitter 32, a clamping device 33, and a material opening 34. The conveyor belt 31 is installed on the inside of the bracket 1, and the laser emitter 32 is embedded in the marking box 3. At the top, the clamping device 33 is installed at the inner bottom of the marking box 3 , and the material opening 34 is arranged on both sides of the bottom of the marking box 3 .

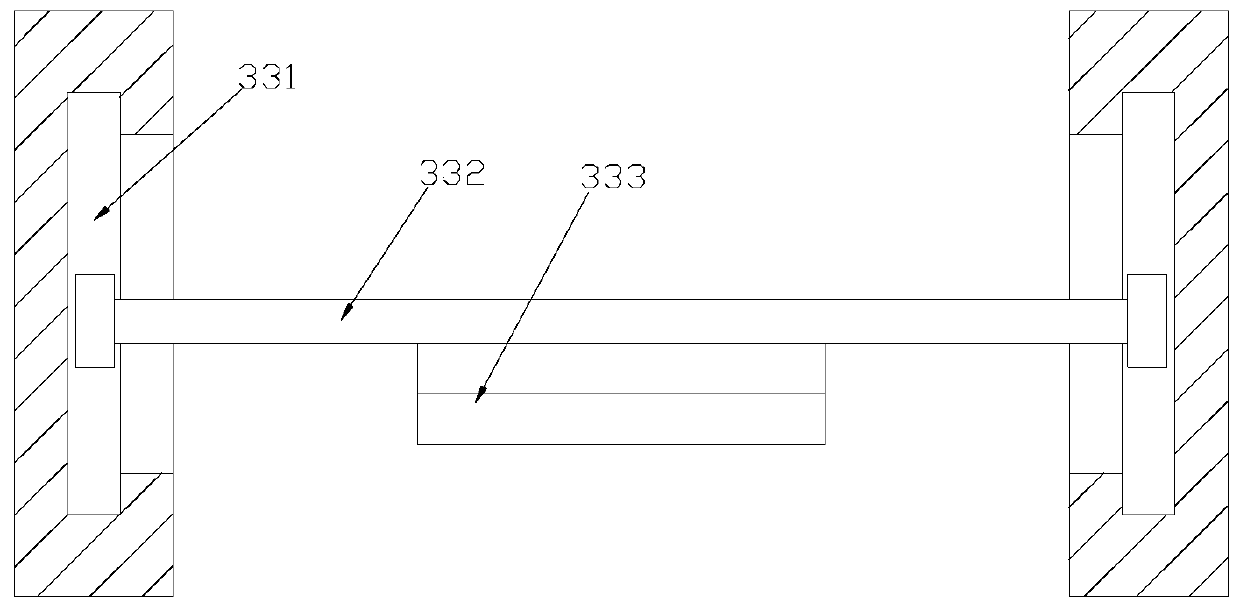

[0028] The clamping device 33 includes a slide groove 331, a support rod 332, and a clamp 333. The support rod 332 is installed in the slide groove 331, and the clamp 333 is welded in the middle of the bottom of the support rod 332. The support ...

Embodiment 2

[0032] Example 2: Please refer to Figure 6-Figure 8 The specific embodiments of the present invention are as follows: the guide block a23 is composed of a guide body b1, a slot b2, a contact block b3, and a pressing device b4, the guide body b1 is triangular in shape, and the slot b2 is arranged on the guide body On the slope of b1, there are three contact blocks b3, the contact blocks b3 are horizontally arranged at the bottom of the guide body b1, the pressing device b4 is installed at the rear end of the guide body b1, and the clamping groove b2 is triangular There are three card slots b2, and the card slots b2 are horizontally arranged on the slope of the guide body b1, which is beneficial to block the circuit board on the guide roller a22 through the card slot b2, and prevent the circuit board from sliding down. Condition.

[0033] The pressing device b4 is composed of an engaging groove b41, a second spring b42, and a connecting block b43. The top end of the engaging g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com