Prefabricated building rectangular steel pipe vertical type assembling production line

A rectangular steel tube, assembly technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of assembly quality difficult to meet standards, difficult to adapt to factory intensive production, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

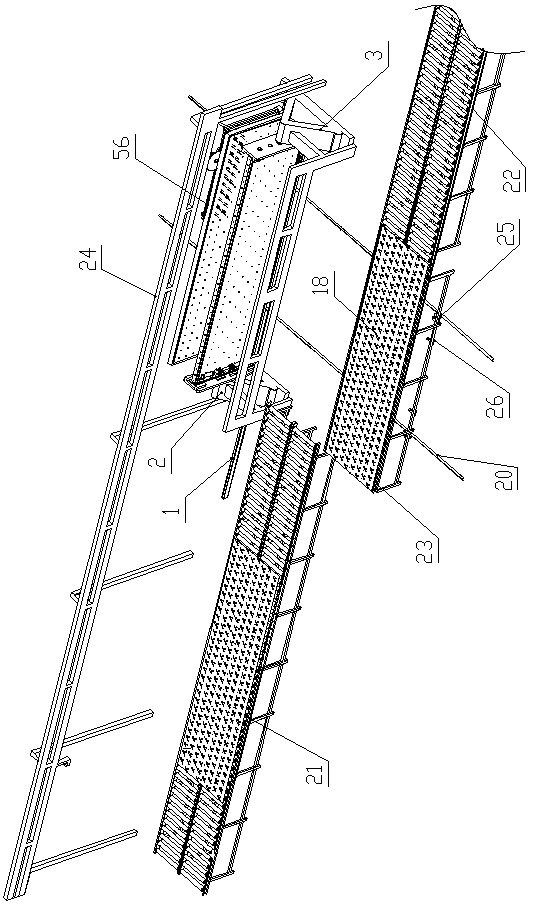

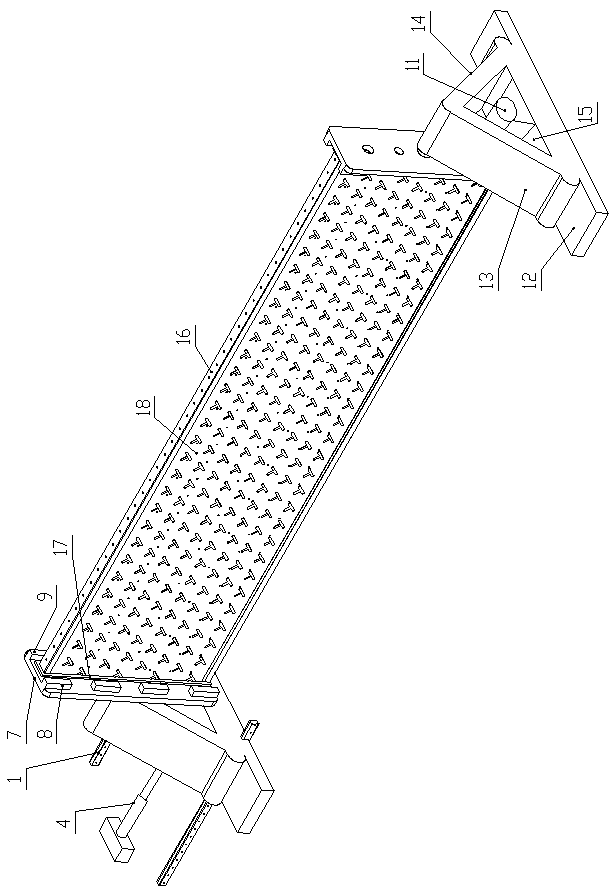

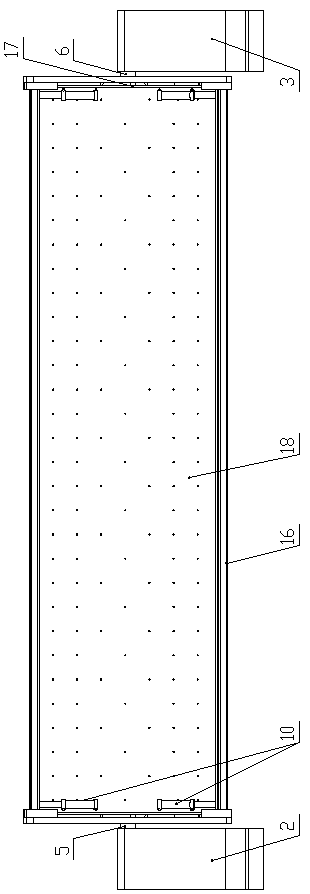

[0042] Such as Figure 1-Figure 6 As shown, the prefabricated building rectangular steel pipe vertical assembly production line of the present invention includes a transverse guide rail 1, a left moving support 2, a right fixed support 3, a longitudinal guide rail 20, a left rectangular steel plate roller conveyor 21, and a right rectangular steel plate roller conveyor 22 , ferry jacking trolley 23, rectangular steel pipe finished product conveying hanger 24 and rib cutting device 56, horizontal guide rail 1 is arranged on the ground along the left and right horizontal directions, and the bottom of left mobile support 2 slides and is arranged on horizontal guide rail 1, and left mobile support 2 The left side is connected with a power drive mechanism 4 for driving the left moving support 2 to slide left and right along the transverse guide rail 1; the left rectangular steel plate roller conveyor 21, the right rectangular steel plate roller conveyor 22, the rectangular steel pip...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap