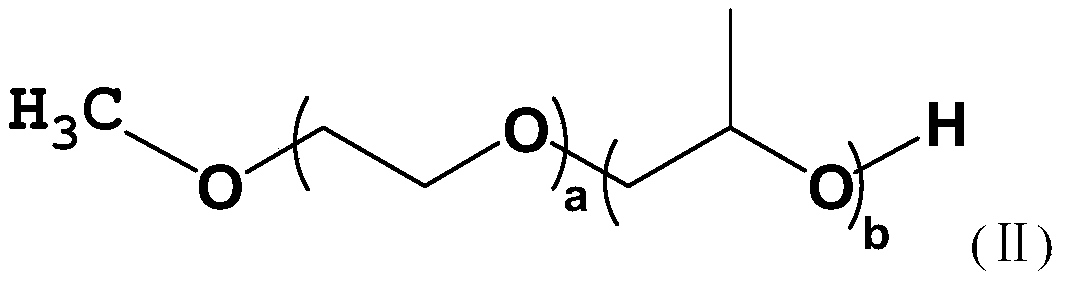

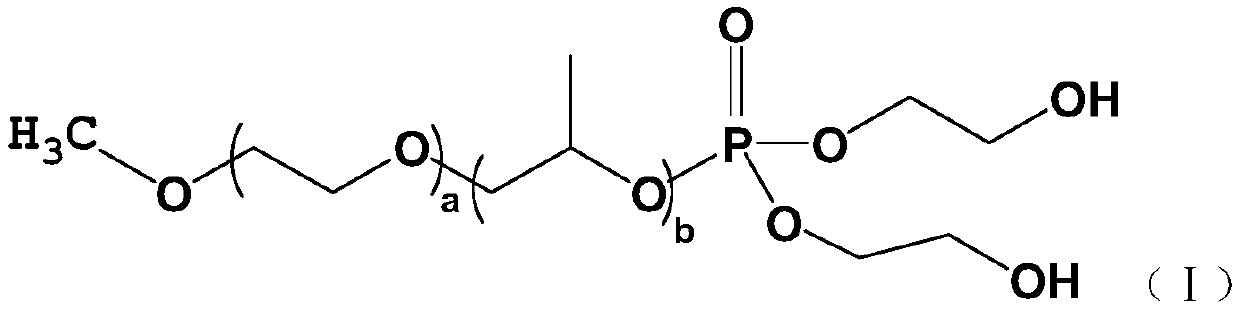

Branched polyether intermediate, preparation method thereof and application of branched polyether intermediate in preparation of phosphorus-containing group micromolecular water reducing agent with medium-low water reducing rate

A branched polyether and intermediate technology, applied in the field of concrete admixture preparation, can solve the problems of low density of adsorption groups and limited performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of Polyether Phosphate P-1

[0043]Weigh 600 parts of methoxypolyether (Mn=600, a=13, b=0) into the reactor, and add 121 parts of 85% phosphoric acid under the condition of keeping warm in a water bath at 50-70°C. Then turn it into an oil bath and raise the temperature to 120°C, keep the reaction pressure at -0.05MPa~-0.1MPa, keep it warm for 15 hours, and obtain a brown-yellow product. According to the liquid phase test, the yield of polyether phosphate P-1 is 98.2%. .

[0044] Similarly, the following polyether phosphates can be prepared.

[0045] P-2: Prepared from methoxy polyether (Mn=1000, a=21, b=1), the yield of polyether phosphate is 97.4%.

[0046] P-3: Prepared from methoxy polyether (Mn=1500, a=30, b=3), the yield of polyether phosphate is 95.5%.

[0047] P-4: Prepared from methoxy polyether (Mn=2000, a=38, b=5), the yield of polyether phosphate is 93.8%.

[0048] P-5: Prepared from methoxy polyether (Mn=2500, a=45, b=9), the yield of polyeth...

Embodiment 2

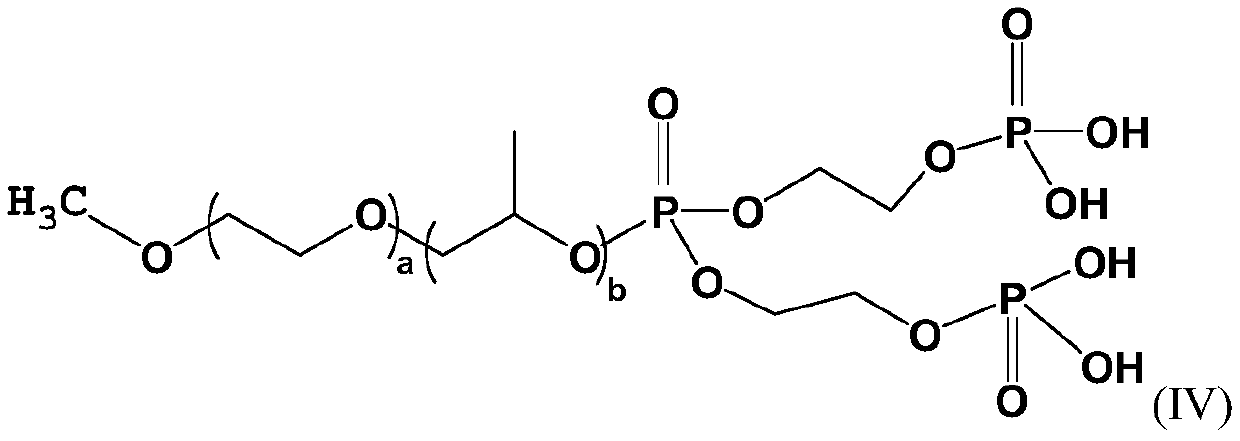

[0051] 300 parts of P-1 were added to the reactor, and the reactor was evacuated to -0.1MPa at room temperature. Then the temperature of the reaction kettle was raised to 80° C., and 44 parts of ethylene oxide was introduced into the reaction kettle. When the pressure in the reaction kettle dropped and the temperature rose slightly, it indicated that the ring-opening reaction started, and the reaction was continued for 1 hour to stop the reaction. Open the vent valve to balance the pressure in the reactor, and open the reactor to discharge. Transfer the material liquid into the reaction bottle, put the reaction bottle into a water bath to lower the system temperature to 50-70°C and maintain the temperature range, add 71.7 parts of phosphorylation reagent phosphorus pentoxide, and then transfer the reaction bottle to an oil bath, Raise the temperature of the reaction system to 100°C, and react for 12 hours under the pressure of -0.05~-0.1MPa to obtain a phosphorus-containing gr...

Embodiment 3

[0053] Add P-2500 parts to the reactor, and vacuumize the reactor to -0.1MPa at room temperature. Then the temperature of the reaction kettle was raised to 90°C, and 60.9 parts of propylene oxide was introduced into the reaction kettle. When the pressure in the reaction kettle dropped and the temperature rose slightly, it indicated that the ring-opening reaction started, and the reaction was continued for 3 hours to stop the reaction. Open the vent valve to balance the pressure in the reactor, and open the reactor to discharge. Transfer the material liquid into the reaction bottle, put the reaction bottle into a water bath to lower the system temperature to 50-70°C and maintain the temperature range, add 121 parts of phosphorylation reagent 85% phosphoric acid, then transfer the reaction bottle to an oil bath, and put The temperature of the reaction system was raised to 110°C. Under the pressure of -0.05~-0.1MPa, the reaction was carried out for 5 hours to obtain a phosphorus-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com