Force-induced responsive multiphase supramolecular block polymer

A technology of block polymers and molecular blocks, applied in the field of force-responsive multi-phase supramolecular block polymers, can solve problems such as difficult to meet the needs of multi-functional and intelligent materials, single properties and performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

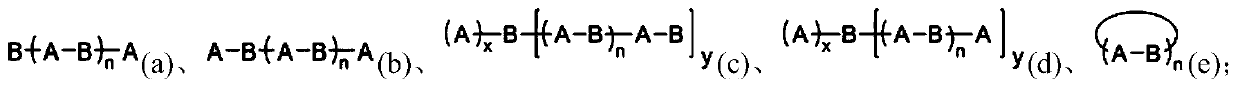

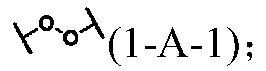

[0040] According to another embodiment of the present invention, there is provided a method for realizing mechanotropic response, which is characterized in that a mechanotropic response heterogeneous supramolecular block polymer is provided, which contains at least one kind of The block polymer supramolecular monomer of section; Contain at least a kind of supramolecular effect in the described block polymer supramolecular monomer, wherein, each hard segment is mixed with each other and / or each independently forms and soft segment Incompatible hard phases to form phase-separated physical crosslinking and / or polymerization based on hard segments, the soft segments of the block polymer molecules are mixed with each other and / or each independently forms an amorphous soft segment phase; the mechanoresponsive multiphase supramolecular block polymer contains a mechanosensitive group, which is located in the supramolecular monomer of the block polymer and / or other supramolecular monome...

Embodiment 1

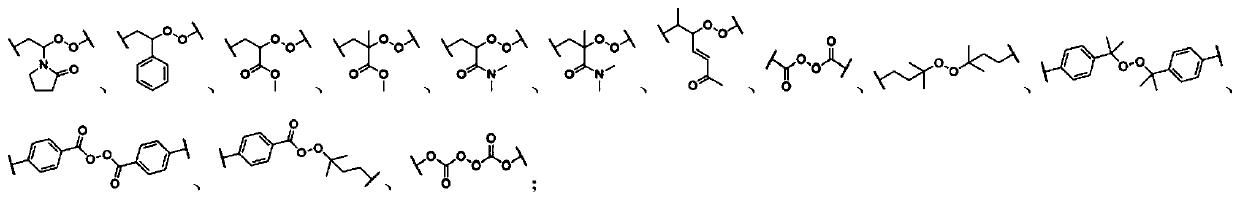

[1760] Example 1 Dissolve limonene oxide and catalyst in toluene under anhydrous and air-free conditions of 90°C, keep the molar ratio of limonene oxide and catalyst at 200:1, feed 10bar carbon dioxide into the reaction vessel, and after the reaction is complete, the crude The product was precipitated with methanol to obtain polylimonene carbonate segment A. Reacting equimolar equivalents of heptafluoro-2-naphthol with mercaptoacetic acid under the catalysis of DCC and DMAP to obtain fluoronaphthalene a with a mercapto group at one end. Polymer A and the resulting compound a, 3-phenyl-1-propanethiol, mercaptoethanol, and 3-mercaptopropionic acid n-butyl react under the catalysis of triethylamine to keep the polymer pendant alkenyl, compound a , 3-phenyl-1-propanethiol, and 3-mercapto propionate in a molar ratio of 10:2:2:1:5 to obtain a polymer B in which some side groups are supramolecular groups. A certain amount of 2-maleimidoacetic acid and polymer B are reacted under the...

Embodiment 2

[1763] Example 2 1-adamantane methanol and excess polypropylene glycol (average molecular weight is about 1000 Da) terminated by carboxyl groups at both ends were reacted under the catalysis of DCC and DMAP to obtain polypropylene glycol A with an adamantyl group at one end and a carboxyl group at the other end. React the obtained polymer A with equimolar equivalents and the compound a containing the mesensitizing group under the catalysis of DCC and DMAP to obtain polypropylene glycol B with an alkenyl group at one end and an adamantyl group at the other end. The obtained polymer B and polyethylene glycol (average molecular weight about 8000 Da) with a mercapto group at one end were subjected to a mercapto-ene click reaction to obtain a diblock polymer C. The mechanotropic responsive heterogeneous supramolecular block polymer of the present invention is obtained by blending the polymer C and the bifunctional cyclodextrin in equimolar equivalents.

[1764]

[1765] The micell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com