Application of alpha alumina abrasive in PI material polishing

A technology of alpha alumina and abrasives, which is applied in the direction of polishing compositions containing abrasives, etc., and can solve the problems of limited application range and low polishing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

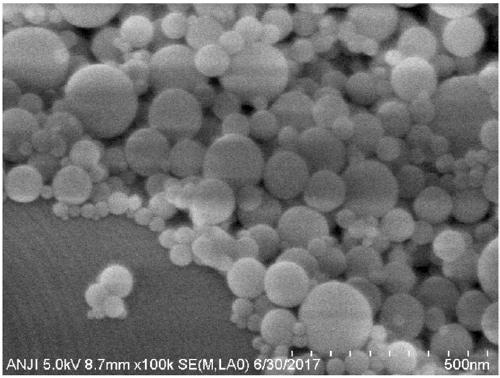

Image

Examples

Embodiment Construction

[0017] The advantages of the present invention are further described below through specific examples, but the protection scope of the present invention is not limited only to the following examples.

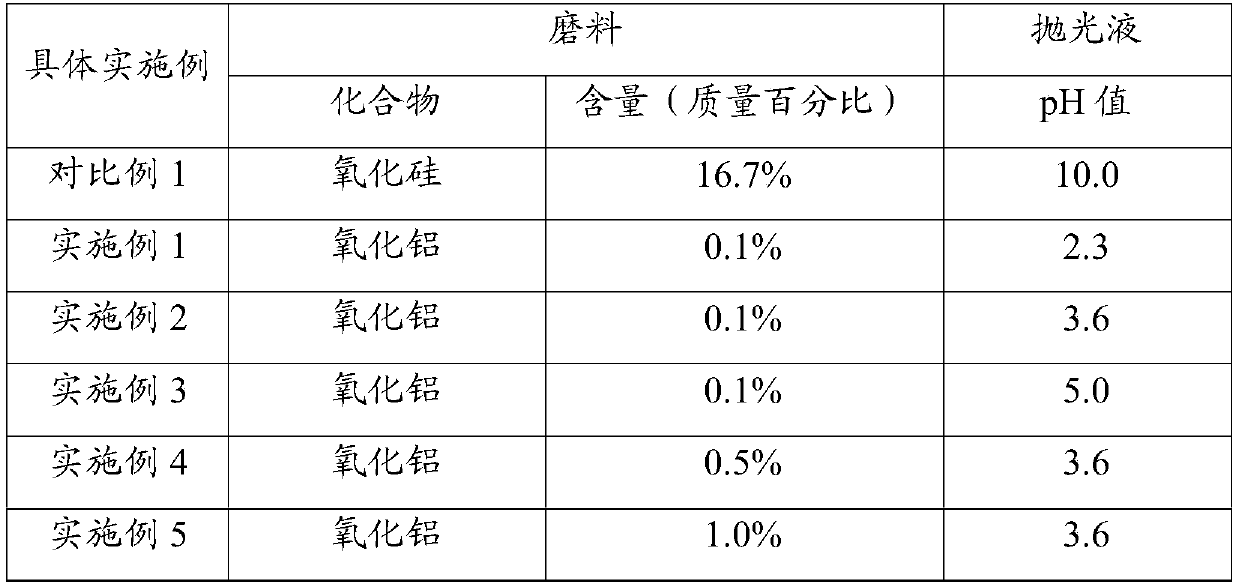

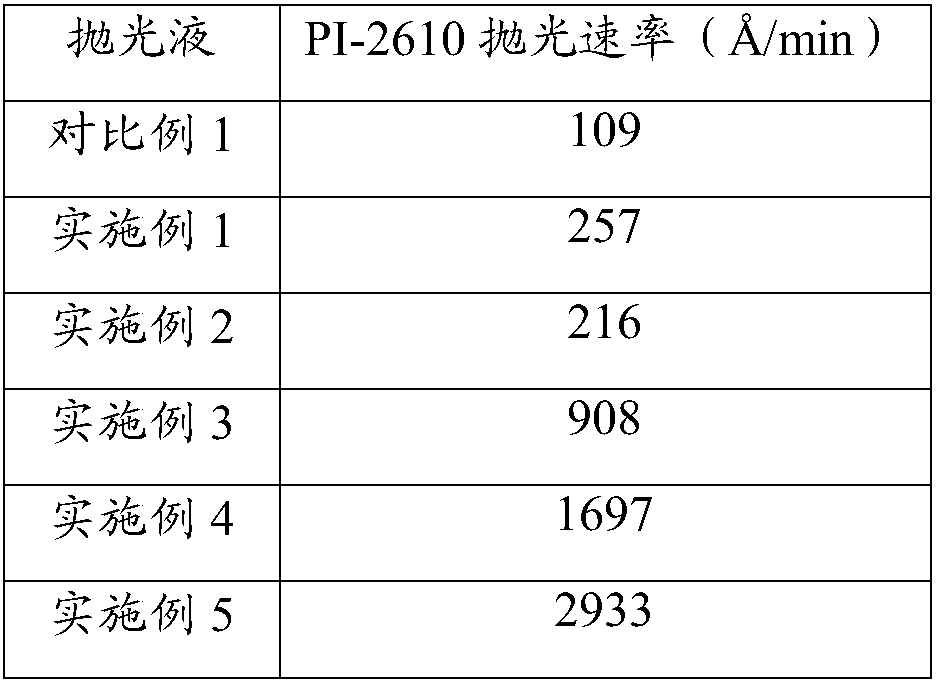

[0018] Table 1 shows Examples 1-5 and Comparative Example 1 of the chemical mechanical polishing fluid of the present invention. Wherein, the embodiment of the present invention adopts the alpha alumina abrasive as acidic alpha alumina.

[0019] Table 1 Comparative Example 1 and polishing fluid 1-5 of the present invention

[0020]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com