Preparation method of in-situ synthetic dual-phase particle reinforced aluminum-based composite material

A technology for particle-reinforced aluminum and composite materials, which is used in the field of in-situ synthesis of dual-phase particle-reinforced aluminum-based composite materials, and can solve the problems of easy particle agglomeration, uneven particle distribution, and harsh reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

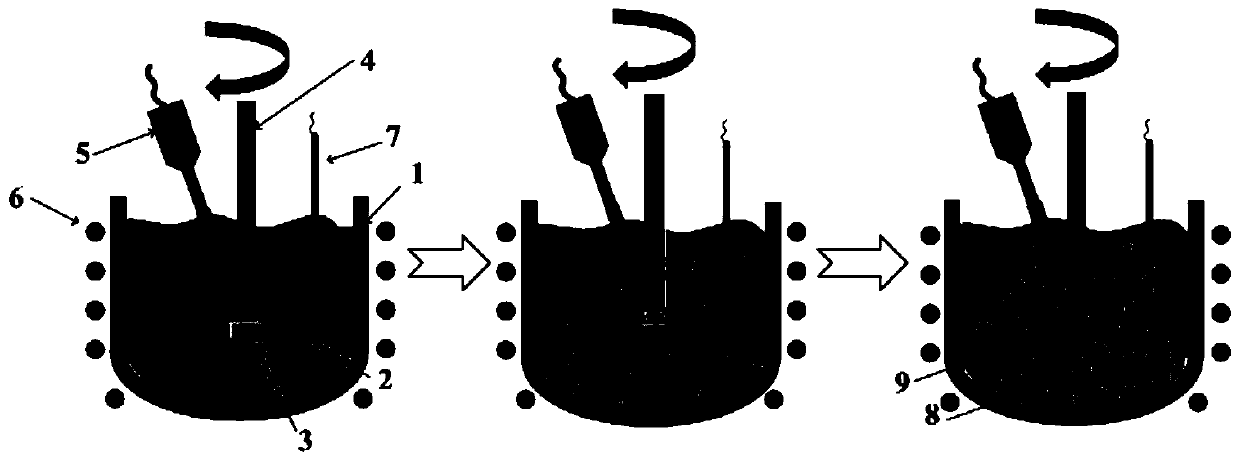

[0036] Such as figure 1 As shown, the present invention is a preparation method of in-situ synthesis of dual-phase particle-reinforced aluminum-based composite materials, which specifically includes the following steps:

[0037] S1) using aluminum / aluminum alloy powder, graphite powder and boron particles as raw materials to make a prefabricated body;

[0038] S2) Embed the preform obtained in S1) into the lower part of the stirring rod, and penetrate deep into the aluminum / aluminum alloy melt, and synthesize dispersed Al through in-situ reaction 3 BC and AlB 2 The dual-phase particle-reinforced aluminum-matrix composite material melt of the particles is cooled to obtain the dual-phase particle-reinforced aluminum-matrix composite material.

[0039] The preparation method also includes S3) a casting process, and S2) is obtained from dispersedly distributed Al 3 BC and AlB 2 Particle-based dual-phase particle-reinforced aluminum-matrix composite melts are cast into shape. ...

Embodiment 1

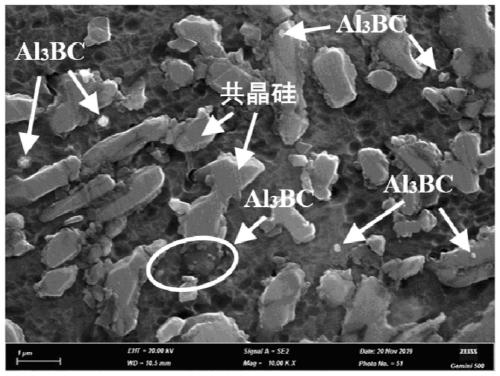

[0053] Embodiment 1: Using the present invention to prepare Al in situ in Al-Si-Fe alloy melt 3 BC and AlB 2 To enhance particles, the steps are as follows:

[0054] (1-1) Weigh 120g of Al-8Si-Fe alloy powder with a particle size of <20μm and a particle size of 0.5-3

[0055] 1. Crucible; 2. Aluminum / aluminum alloy melt; 3. Preform; 4. Stirring rod; 5. Ultrasonic device; 6. Thermocouple; 7. Heating device; 8. AlB 2 Particles; 9, Al 3 BC particles.

[0056] 14g of graphite powder of μm and 20g of boron particles with a particle size of 0.5-2μm;

[0057] (1-2) Mix the aluminum / aluminum alloy powder and the graphite powder and then ball mill it for 20 hours, then mix it with the boron particles and continue the ball milling for 8 hours, then cold press and form it into a prefabricated body for later use;

[0058] (1-3) Melting 1 kg of Al-8Si-Fe aluminum alloy and placing it in the crucible 1, heating the heating device 8 after refining, degassing, and removing slag, and cont...

Embodiment 2

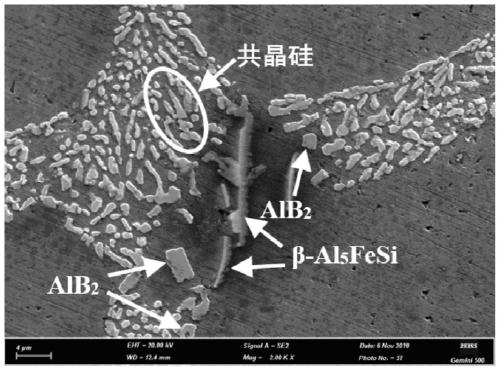

[0062] Embodiment 2: Using the present invention to prepare Al in situ in aluminum melt 3 BC and AlB 2 To enhance particles, the steps are as follows:

[0063] (1-1) Weigh 150 g of Al powder with a particle size of <30 μm, 18 g of graphite powder with a particle size of 0.5-3 μm, and 30 g of boron particles with a particle size of 0.5-2 μm;

[0064] (1-2) Mix the aluminum / aluminum alloy powder and the graphite powder and then ball mill it for 16 hours, then mix it with the boron particles and continue the ball milling for 7 hours, then cold press and form it into a prefabricated body for later use;

[0065] (1-3) Melting 1.8kg of aluminum, after refining, degassing, and slag removal, set the melt temperature to 720°C for heat preservation;

[0066] (1-4) Insert the prefabricated body into the lower part of the stirring rod, and stir and rotate it deep into the aluminum / aluminum alloy melt. The prefabricated body melts and falls off layer by layer in the melt, and the boron a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap