HVOF method for mining hydraulic support

A hydraulic support and mining technology, which is applied in metal material coating process, fusion spraying, coating, etc., can solve the problems of complex working conditions of mining hydraulic support and the unsuccessful application of supersonic flame spraying process, etc., to achieve The effect of good wear and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be further described in detail below. The content not described in detail in the embodiments of the present invention belongs to the prior art known to those skilled in the art.

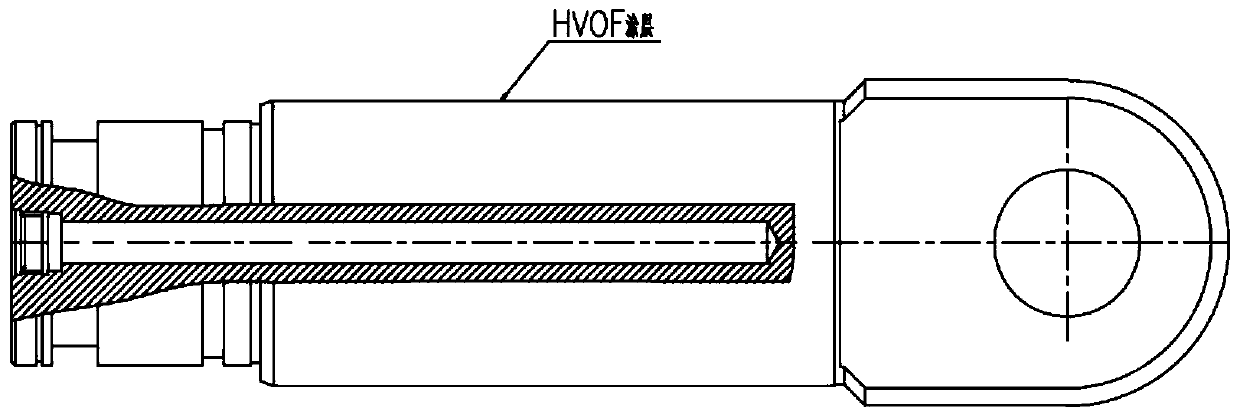

[0015] The present invention is used for the HVOF method on the mine hydraulic support, and its preferred embodiment is as follows figure 1 Shown:

[0016] The surface treatment of mining hydraulic support is carried out by supersonic thermal spraying, and a layer of supersonic thermal spraying coating (HVOF coating) is formed on the surface of hydraulic support.

[0017] The supersonic thermal spray coating includes a tungsten carbide coating.

[0018] The method is used for the surface treatment of the piston rod, the live column, and the outer circle wearing section of the middle cylinder body of the mine hydraulic support.

[0019] The HVOF method used in mine hydraulic supports of the present invention adopts supersonic thermal spraying to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com