Freshness indicating electrostatic spinning fiber membrane, and preparation method and application thereof

A technology of electrospinning and fiber membrane, which is applied in the field of freshness-indicating electrospinning fiber membrane and its preparation, which can solve the problems of high spoilage rate, economic loss, and whether the meat is fresh or not

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

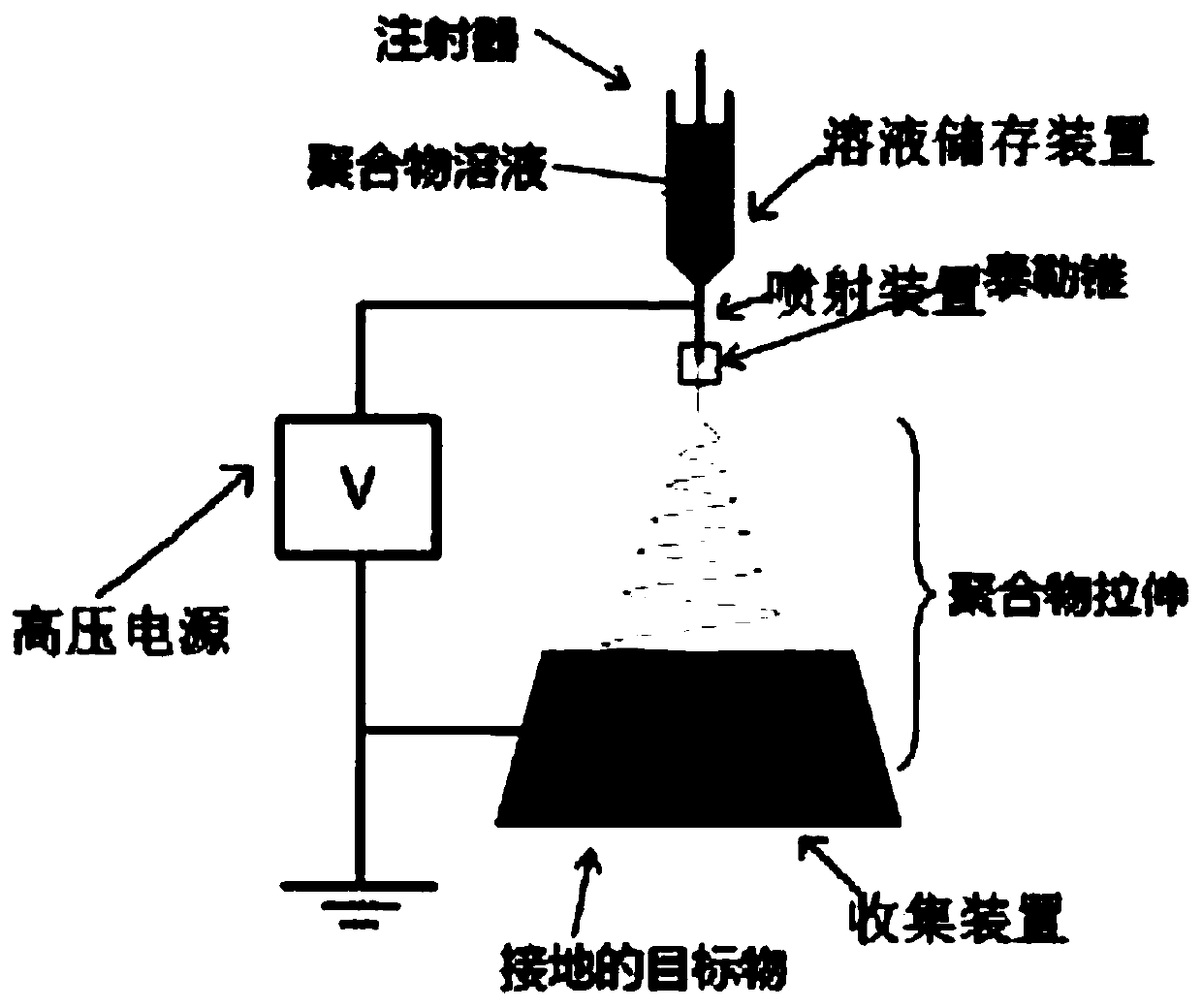

[0083] A method for preparing an electrospun fiber membrane, comprising the following steps:

[0084] 1) Evenly disperse 10g of polyvinyl alcohol into 100mL of distilled water, heat at 80°C for 30min under agitation to dissolve the polyvinyl alcohol in distilled water, let it cool down to room temperature 20-25°C, add 12mL of bromocresol Stir evenly after the purple ethanol solution, the concentration of bromocresol purple in the bromocresol purple ethanol solution is B wt%, then adjust the pH value to 5 by adding the NaOH aqueous solution of 1mol / L, degassing after mixing (deaeration: static placed until no bubbles), to obtain a mixture;

[0085] 2) Use an electrospinning device to spin the mixture obtained in step 1) into a film to obtain an electrospun fiber film, dry it at a room temperature of 20-25°C until the film can be torn off, and then use it, wherein the spinning speed is 0.5ml / h, the spinning voltage of the electrospinning device is 18kV, the diameter of the nee...

Embodiment 5~7

[0090] A method for preparing an electrospun fiber membrane, comprising the following steps:

[0091] 1) Evenly disperse 10g of polyvinyl alcohol into 100mL of distilled water, heat at 80°C for 30min under agitation to dissolve the polyvinyl alcohol in distilled water, let it cool down to room temperature 20-25°C, add 12mL of bromocresol Stir evenly after the purple ethanol solution, the concentration of bromocresol purple in the bromocresol purple ethanol solution is 0.5wt%, then adjust the pH value to 5 by adding the NaOH aqueous solution of 1mol / L, degassing after mixing (defoaming: static placed until no bubbles), to obtain a mixture;

[0092] 2) Use an electrospinning device to spin the mixture obtained in step 1) into a film to obtain an electrospun fiber film, dry it at a room temperature of 20-25°C until the film can be torn off, and then use it, wherein the spinning speed is 0.5ml / h, the spinning voltage of the electrospinning device is D kV, the diameter of the nee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Needle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com