Wind power generator paddle lightning wire breakage testing system and method

A technology of wind power generator and test system, which is applied in the direction of wind power generator, wind power generator monitoring, wind power generation, etc., and can solve the problems of low efficiency, huge labor and mechanical usage costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

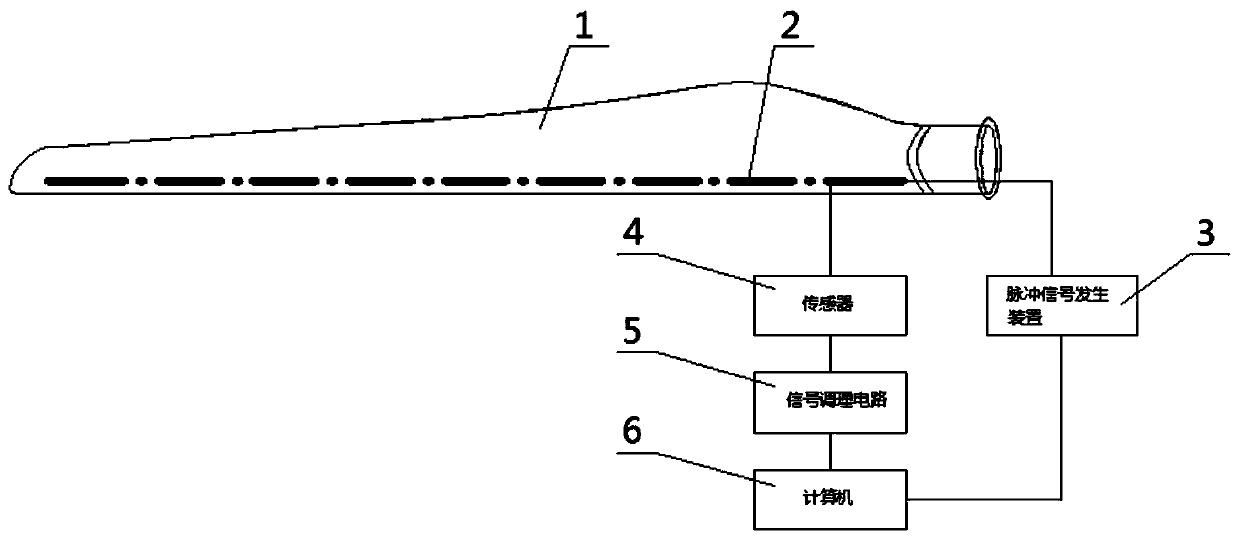

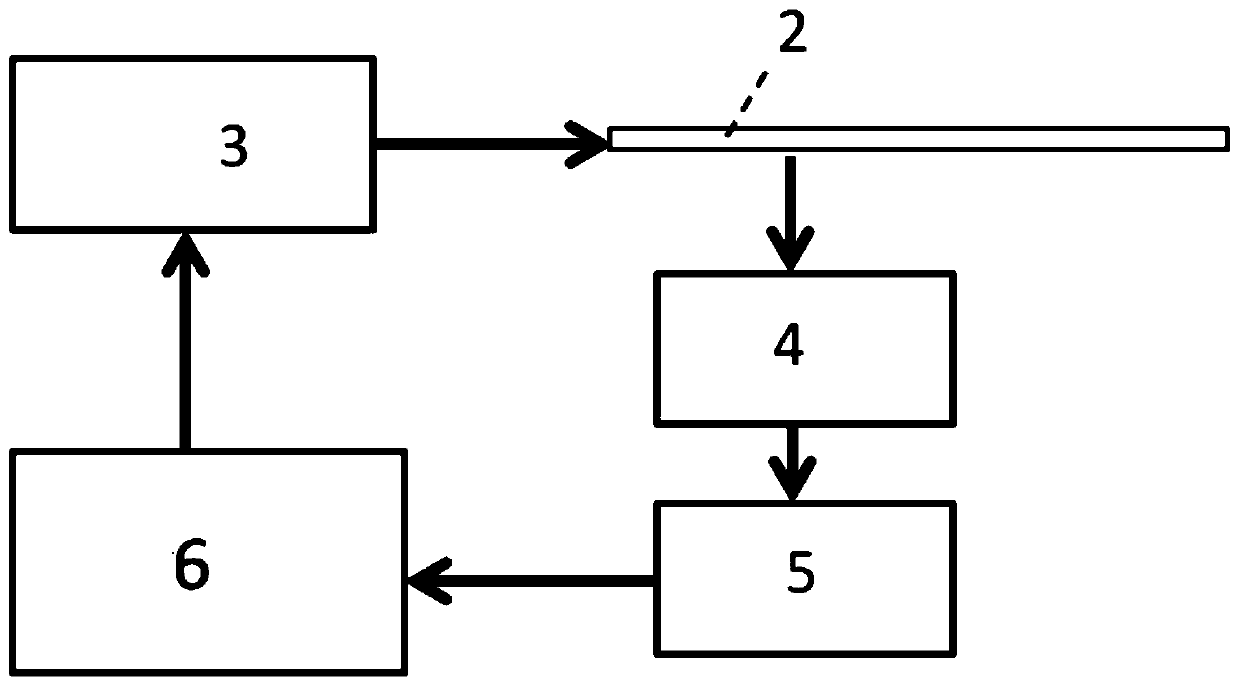

[0045] Specific implementation mode one: refer to Figure 1-Figure 9 Describe this embodiment, a wind power generator blade lightning protection wire breakage testing system in this embodiment, including a blade 1 and a lightning protection wire 2 arranged in the blade, the lightning protection wire 2 is glued to the inner wall of the blade 1, The lightning protection wire 2 is arranged from the blade tip of the blade 1 to the blade root of the blade 1, and the lightning protection wire 2 at the blade root of the blade 1 is loaded with a pulse signal generating device 3, and the lightning protection wire 2 is covered with a sensor 4, The sensor 4 establishes a signal transmission connection with the computer 6 through the signal conditioning circuit 5 , and the computer 6 controls the pulse signal generator 3 to send out a pulse signal and load it on the lightning conductor 2 .

[0046] Such as figure 1 As shown, the lightning protection wire in the wind turbine blade is laid...

specific Embodiment approach 2

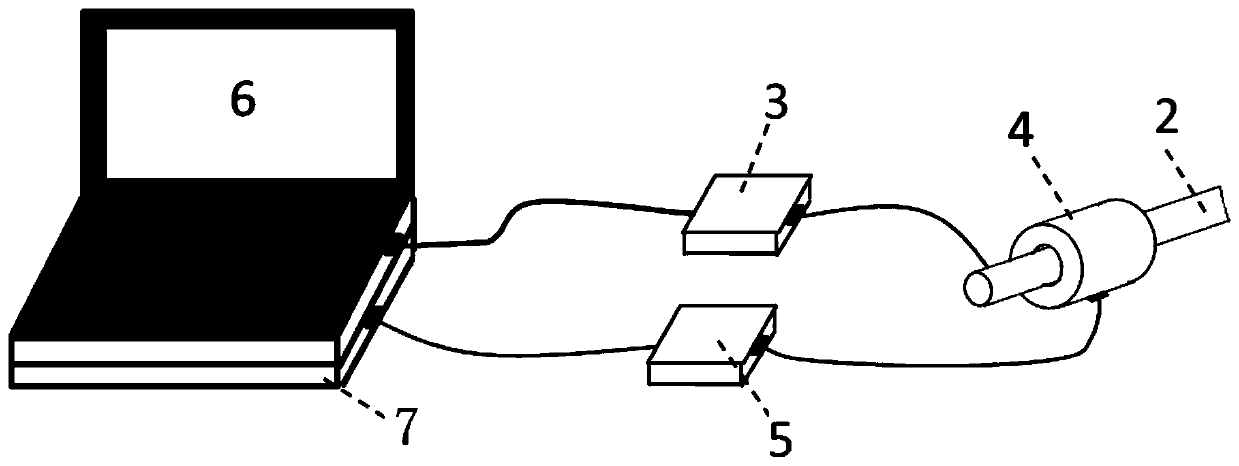

[0057] Specific implementation mode two: refer to Figure 1-Figure 9 This embodiment will be described. In this embodiment, a wind turbine blade lightning conductor breakage testing system, the sensor 4 is a Rogowski coil current sensor. The Rogowski coil current sensor coil has a certain number of turns. When the current in the wire changes, an induced potential will be generated in the sensor. The Rogowski coil is suitable for the measurement of alternating current in a wide frequency range, and has no influence on the conductor and size. Special requirements, the application of the Rogowski current sensor in the measurement of lightning wire breakage has a faster instantaneous response capability.

specific Embodiment approach 3

[0058] Specific implementation mode three: refer to Figure 1-Figure 9 , in combination with specific implementations 1 and 2, this implementation is described. In this implementation, a wind turbine blade lightning protection wire breakage testing system, the sensor 4 uses a Rogowski coil with 16 turns, and the pulse signal adopts The pulse signal source module sends out a square wave signal with a frequency of 500KHz and a peak-to-peak value of 10V, such as figure 1 As shown, the sensor signal enters the conditioning amplifier module to adjust the signal amplitude to ±5V. The response speed of the conditioning amplifier module is 7ns. The signal after conditioning enters the high-speed acquisition card, and the acquisition card obtains the traveling wave in the lightning protection line. Signal, the high-speed data acquisition card has a sampling speed of 2.5GSPS and a bandwidth of 1.5GHz. As mentioned above, the signal wires are all shielded wires, and the connection method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com