Lighting appliance

A lamp and light source technology, applied in the field of lamp units, can solve problems such as not easy to ensure the space for configuring it, increase in size of lamp units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

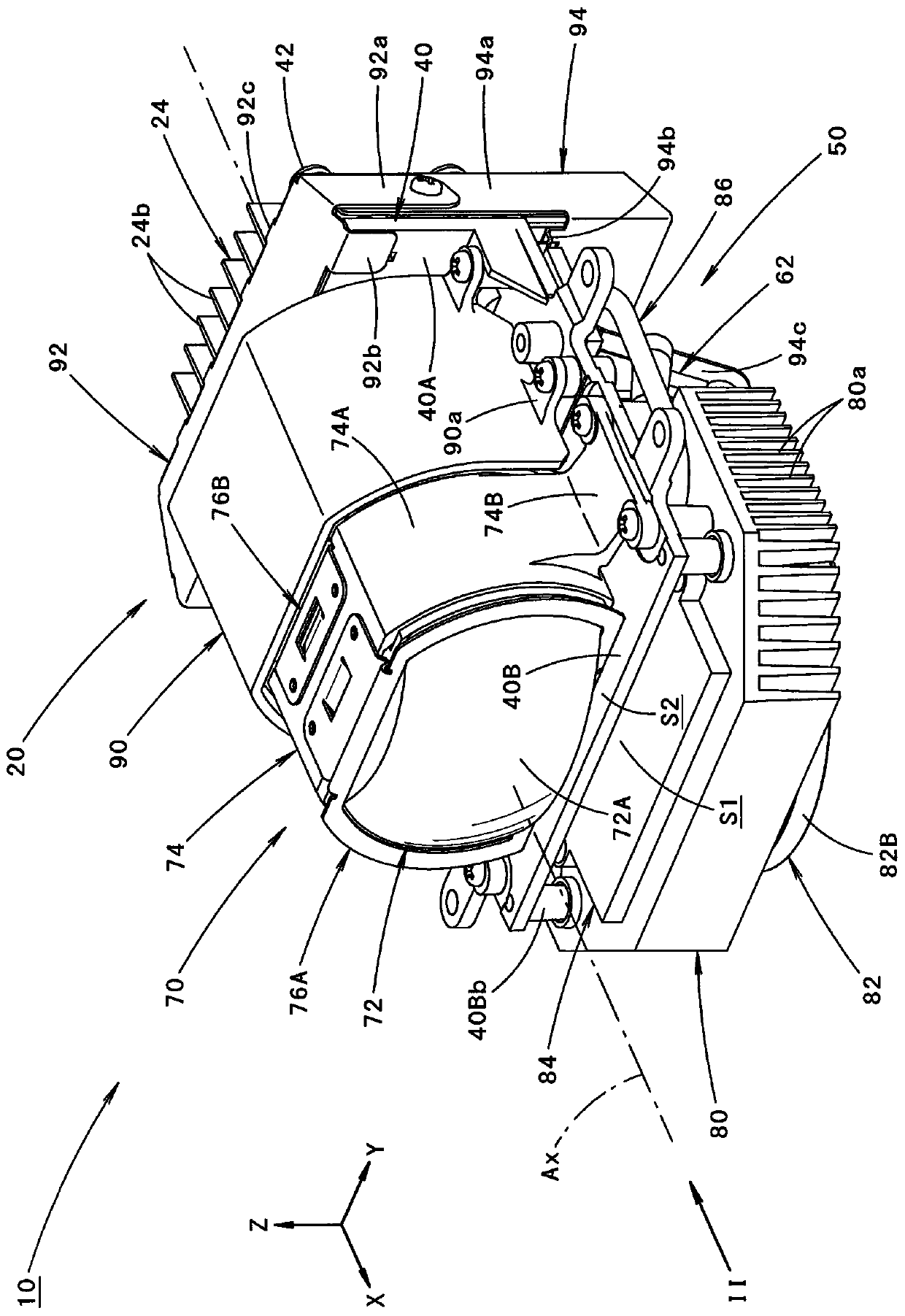

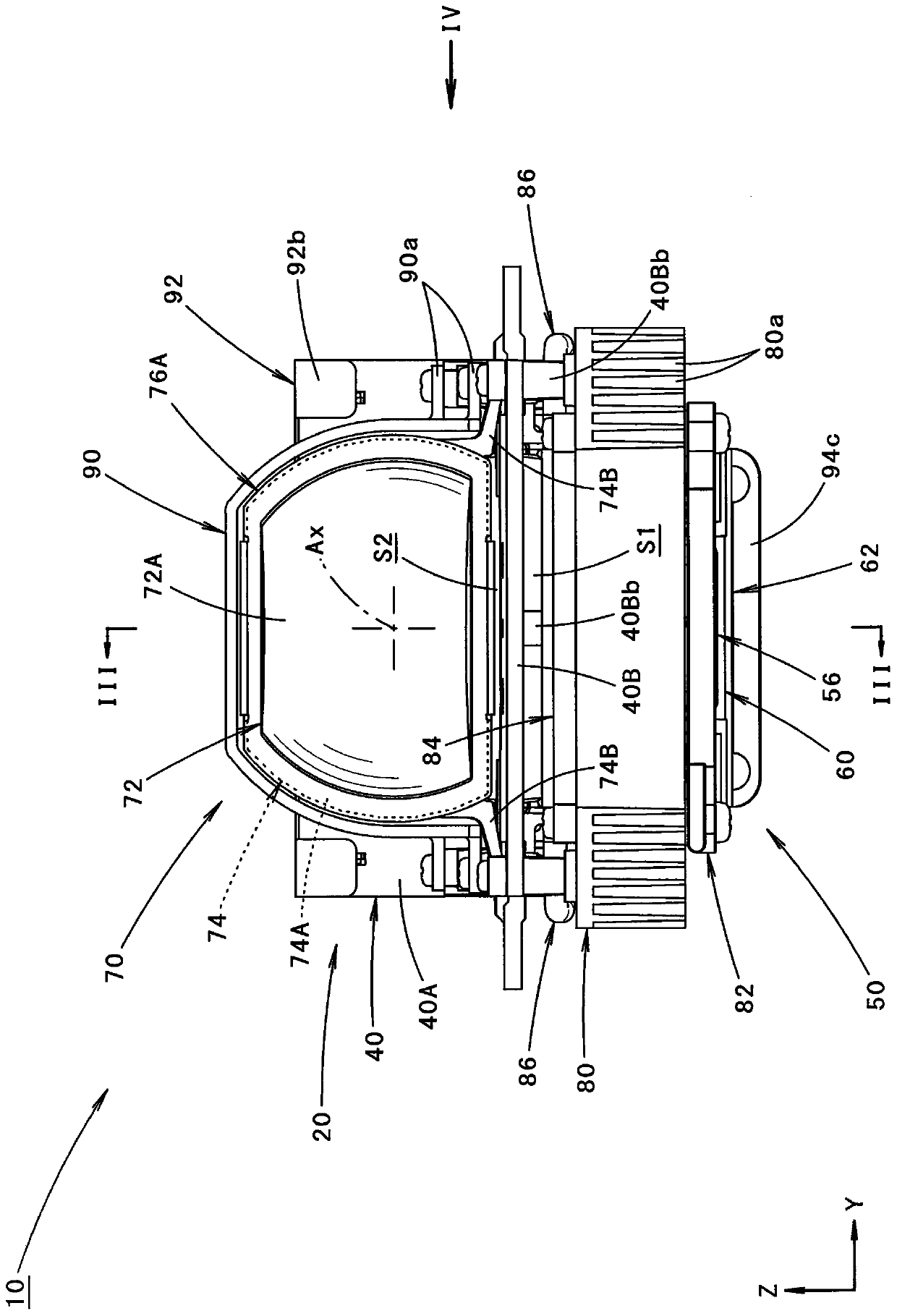

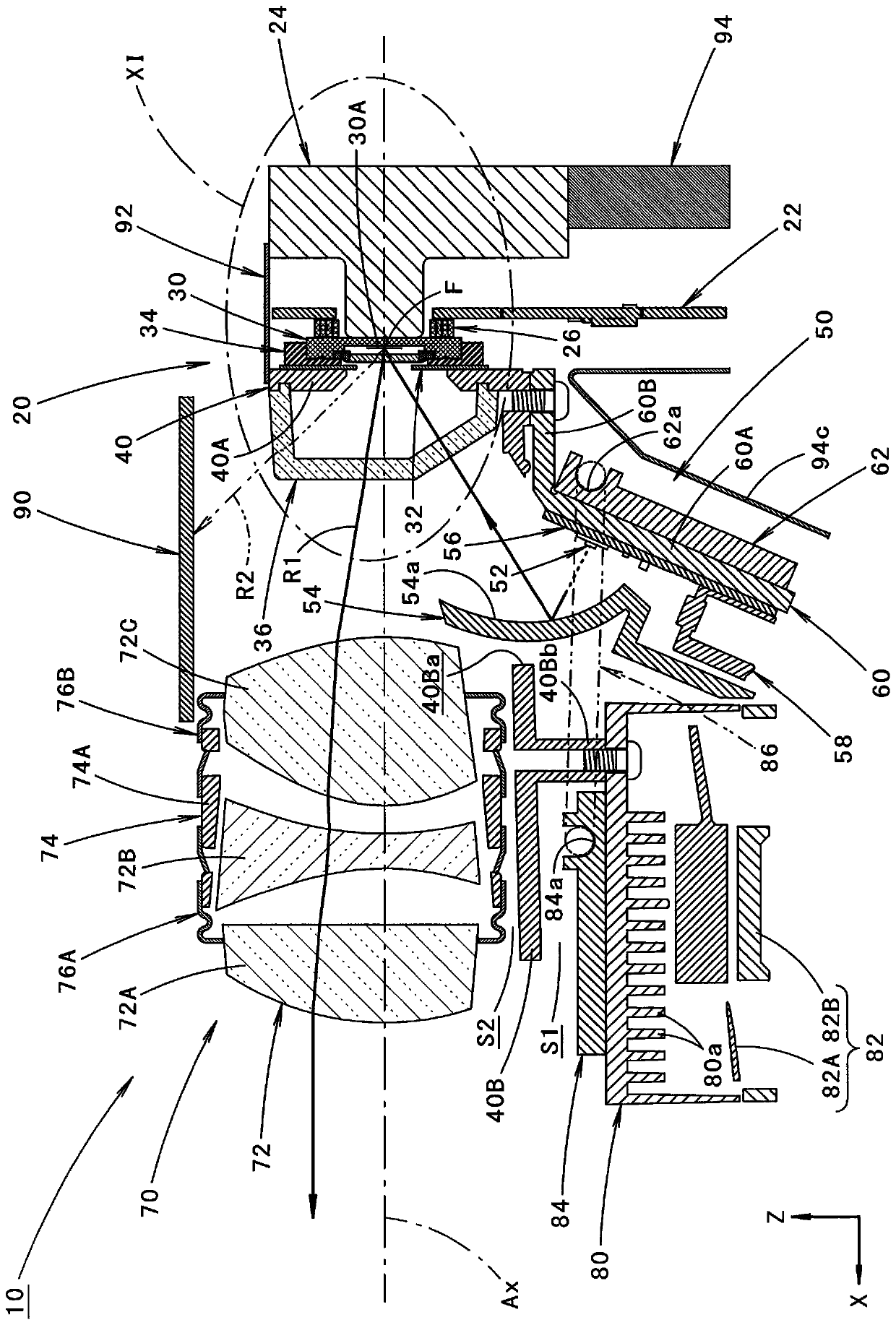

[0046] figure 1 is a perspective view showing a lamp unit 10 according to an embodiment of the present invention, figure 2 yes figure 1 II direction view. in addition, image 3 yes figure 2 Sectional view of line III-III, Figure 4 yes figure 2 View in the direction of IV. in addition, Figure 5 yes Figure 4 The V-direction view, Figure 6 yes Figure 4 VI direction to the view, Figure 7 yes Figure 4 View from direction VII.

[0047] In these figures, the direction indicated by X is "unit front", the direction indicated by Y is "left direction" perpendicular to "unit front" ("right direction" when the unit is viewed from the front), and the direction indicated by Z is " up direction". The same applies to other figures.

[0048] The lamp unit 10 of this embodiment can be assembled into Figure 14 The state of the vehicular lamp 100 shown in the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com